Introduction

D2 and D6 steel are both high-carbon, high-chromium cold-work tool steels, but they are built for different wear mechanisms. D2 is designed for metal-to-metal contact and mixed loading, using chromium carbides in a martensitic matrix. D6 contains more carbon and tungsten, which produces a higher volume of harder carbides for resistance to mineral, ceramic, and glass-fiber abrasion.

Although their hardness ranges overlap, their microstructures respond very differently to abrasive particles, heat, and section size. This difference determines which steel maintains edge and dimensional stability in service.

Why ASTM D6 Cannot Be Replaced by D2

ASTM D6 and D2 both belong to the high-carbon, high-chromium cold-work tool steel family, but they are designed for different wear mechanisms. D2 is optimized for metal-to-metal contact under mixed abrasion and impact, while D6 is engineered specifically for abrasive mineral environments.

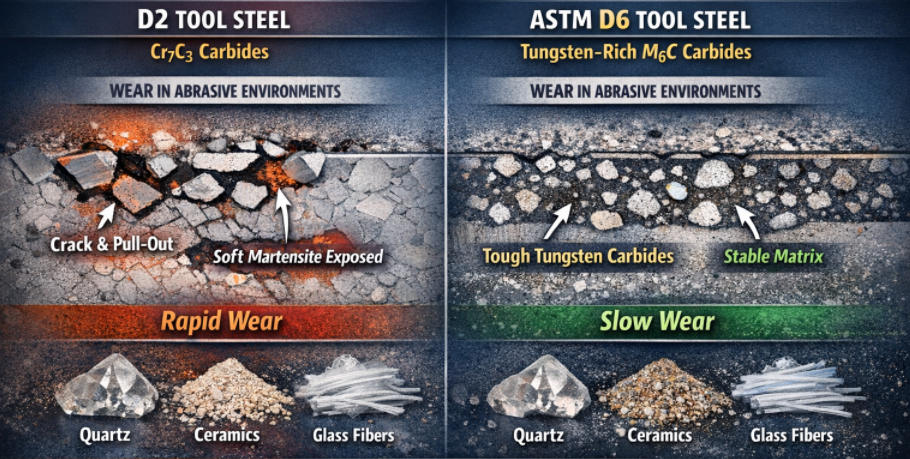

The main difference is carbide chemistry. D6 contains higher carbon and added tungsten, which forms a dense population of tungsten-rich M₆C carbides in addition to chromium carbides. These carbides are harder and more stable than the Cr₇C₃ carbides that dominate D2. When exposed to quartz, ceramic powders, glass fibers, or mineral fillers, D2’s chromium carbides tend to crack or be pulled out, exposing the softer martensitic matrix and accelerating surface wear.

In D6, tungsten-rich carbides resist micro-fracture and particle cutting, so abrasive particles are more likely to wear themselves rather than the steel. This leads to much slower dimensional loss in mineral-rich service.

Chemical and Microstructural Comparison

| Element | D2 (typical) | ASTM D6 (typical) |

|---|---|---|

| Carbon | 1.40–1.60% | 2.00–2.20% |

| Chromium | 11.0–13.0% | 11.5–12.5% |

| Tungsten | – | 0.6–0.9% |

| Molybdenum | 0.7–1.2% | – |

| Vanadium | 0.8–1.1% | 0.3–0.5% |

D2 relies on chromium, molybdenum, and vanadium to form fine chromium-based carbides, mainly Cr₇C₃, dispersed in a martensitic matrix. This produces good wear resistance but keeps the carbides relatively small and brittle.ASTM D6 uses much higher carbon and adds tungsten, which shifts the carbide system. In addition to Cr₇C₃, D6 forms tungsten-rich M₆C carbides. These carbides are harder, more thermally stable, and far more resistant to micro-fracture when struck by abrasive mineral particles.This changes the total carbide population inside the steel:

| Steel | Total carbide volume |

|---|---|

| D2 | ~15–18% |

| ASTM D6 | ~22–25% |

That extra 5–8% carbide is not cosmetic. It means a much larger portion of the cutting or forming surface is protected by extremely hard particles instead of softer steel matrix. In abrasive service, this directly translates into slower material loss, better edge stability, and longer dimensional life.

Hot Hardness and Dimensional Stability

Many abrasive processes also generate heat. Glass-filled plastics, ceramic pressing, and mineral-loaded polymers all produce frictional heating at the tool surface, often reaching 250–350 °C in continuous production.

At these temperatures, carbide type matters more than bulk hardness. The chromium carbides that dominate D2 begin to lose stability. Their hardness drops and they become more prone to micro-fracture and pull-out. Once this happens, the steel matrix is exposed, and wear accelerates while dimensions drift.

ASTM D6 behaves differently because of its tungsten-rich M₆C carbides. “The tungsten-rich carbide system and secondary hardening delay softening of the matrix at 250–350°C.” They resist softening and do not dissolve or coarsen as quickly, so the abrasive resistance of the surface remains stable even as heat builds up.

This thermal stability is why D6 is widely used for:

- Ceramic tile and technical-ceramic pressing dies

- Refractory and powder-forming tools

- Glass-fiber-filled plastic molds

- Mineral-slurry extrusion and shaping components

In these applications, maintaining edge geometry and die size under heat is just as important as resisting wear.

Through-Hardening in Large Sections

ASTM D6 also outperforms D2 when tools become thick and massive. Its very high carbon content combined with tungsten gives it stronger hardenability, allowing martensite and carbides to form deep into the core during quenching.

In practical heat treatment, the difference becomes obvious as section size increases:

| Section thickness | D2 | ASTM D6 |

|---|---|---|

| 50 mm | Fully hardened | Fully hardened |

| 150 mm | Slight hardness drop | Uniform hardness |

| 250 mm | Risk of soft core | “D6 maintains >58–60 HRC much deeper into the section than D2” |

D2 air-hardens well in moderate sizes, but in large blocks the cooling rate at the core is too slow. This allows retained austenite and softer transformation products to remain, creating a tough but weak center under a hard surface.

In ceramic dies, wear plates, and mineral-processing blocks, this soft core is dangerous. It allows the hard outer layer to flex, crack, and eventually collapse. D6’s stronger through-hardening keeps the entire section rigid and wear resistant, greatly improving structural and dimensional stability in large abrasive tools.

D2 vs ASTM D6 — Cost Structure Comparison

Material cost is just one piece of your total tooling budget. “Typical market pricing in bar stock shows D6 about 8–12% higher than D2 due to tungsten content.The high chromium and tungsten content suggests $4.00-4.50 per pound. That’s an 8-10% premium over D2, or about the same tier.

The raw material difference looks minimal. The real cost gap shows up during machining and heat treatment.

| Cost factor | D2 Tool Steel | ASTM D6 Tool Steel |

|---|---|---|

| Raw material price | Lower | ~8–10% higher (W alloying) |

| Machining speed | Normal | 20–40% slower due to hard carbides |

| Tool wear during machining | Moderate | High (carbide and grinding wheel consumption) |

| Heat treatment | Air quench, simple | Oil / high-pressure gas, triple temper |

| Heat-treat distortion risk | Low | Medium–high if not controlled |

| Heat-treat cost | Standard | +15–25% higher |

| Tool life in mineral abrasion | Baseline | 3–4× longer |

| Die change frequency | High | Much lower |

| Cost per produced part | Increases rapidly with wear | Drops sharply in abrasive service |

Expert Note

ASTM D6 is expensive in the workshop but cheap on the production floor.

Most buyers focus on the purchase price and machining cost, where D6 always looks worse than D2. That is misleading. In mineral-filled plastics, ceramic powder pressing, glass-fiber molding, or slurry extrusion, D2 typically loses its cutting edge and dimensional accuracy far earlier because its chromium carbides are attacked by quartz and alumina. D6’s tungsten-rich carbides survive those environments, so the die runs several times longer.

When downtime, tool changes, regrinding, and scrap rate are included, D6 almost always delivers a lower cost per finished part in high-abrasion service — even though it costs more to machine and heat treat.

D2 vs ASTM D6 — Application Selection Guide

| Working condition | D2 Tool Steel | ASTM D6 Tool Steel |

|---|---|---|

| Sheet metal stamping | Standard low-alloy and mild steel | High-silicon electrical steel, abrasive coatings |

| Blanking & punching | General cold work, moderate runs | Not recommended (risk of chipping) |

| Deep drawing | Simple geometry, good lubrication | Stainless steel, high friction, galling-prone parts |

| Plastic molding | Unfilled or lightly filled polymers | Glass-fiber, mineral-filled, ceramic-filled plastics |

| Cutting & slitting | Paper, cardboard, wood, mild metals | Ceramic tiles, bricks, abrasive sheets |

| Forming rolls | Tube and rim forming | Grit-contaminated rolling, sizing, crushing |

| Die block thickness | ≤150 mm preferred | Large wear blocks, thick ceramic dies |

Engineering Note

D2 is a balanced cold-work steel. It tolerates impact, misalignment, and cyclic stress reasonably well while offering good wear resistance. That makes it ideal for punching, blanking, and mixed-duty tooling.

ASTM D6 is a pure abrasion steel. Its tungsten-rich carbide network is engineered for continuous sliding, grinding, and mineral attack — not for shock. In ceramic pressing, glass-fiber molding, or quartz-filled plastics, D6 can last several times longer than D2 because its carbides are harder than the abrasive. But in punching or impact loading, the same carbide network becomes a liability and leads to chipping or cracking.

In short: D2 survives force.D6 survives sand.

Technical Reference — Chemical Specs & Heat Treatment

D2 and ASTM D6 may look similar on a datasheet, but their chemistry drives very different carbide systems and heat-treatment behavior.

Chemical comparison

| Element | D2 (wt%) | ASTM D6 (wt%) | Effect on performance |

|---|---|---|---|

| Carbon | 1.40–1.60 | 2.00–2.10 | D6 forms a denser carbide network |

| Chromium | 11.0–13.0 | 10.0–12.0 | Similar corrosion and base wear resistance |

| Tungsten | – | 0.50–0.90 | D6 gains stable W-rich carbides |

| Molybdenum | 0.70–1.20 | Trace–0.30 | D2 hardens deeper |

| Vanadium | 0.70–1.10 | 0.20–0.50 | D2 keeps finer grain size |

D2’s molybdenum and vanadium support a fine chromium-carbide structure with good hardenability. D6 replaces that balance with much higher carbon and tungsten, creating large volumes of tungsten-rich carbides that dominate its wear behavior.

D2 heat treatment — air hardening for dimensional control

D2 is austenitized at 980–1010 °C to dissolve enough chromium carbides into solution. Air quenching to about 65 °C produces uniform martensite through sections up to ~150 mm thick, reaching ~64 HRC as-quenched.

Air cooling keeps distortion very low (typically <0.1%), which is why D2 is favored for precision dies. A double temper at 150–230 °C reduces hardness to 58–62 HRC and stabilizes the structure. Tensile strength at this condition is around 1900 MPa. Tempering above ~540 °C should be avoided, as chromium carbides coarsen and hardness drops rapidly.

ASTM D6 heat treatment — secondary hardening control

D6 austenitizes lower, at 940–980 °C, to prevent excessive dissolution of tungsten carbides. Soak time is typically 1 hour per 25 mm of section. Oil or high-pressure gas quenching to ~60 °C gives 64–65 HRC as-quenched, with retained austenite usually below 10% near 960 °C.

D6 requires multiple high-temperature tempers to stabilize. Triple tempering at 540–560 °C triggers secondary hardening from tungsten carbides:

| Temper condition | D6 hardness |

|---|---|

| As-quenched | 64–65 HRC |

| 540 °C (1×) | ~62 HRC |

| 560 °C (3×) | 58–60 HRC |

| >600 °C | <55 HRC |

During these tempers, tungsten-rich carbides precipitate and lock the microstructure. This resists the softening that affects D2 at similar temperatures and gives D6 better dimensional stability during heat treatment, even though both steels end up in a similar working hardness range.

Conclusion

D2 is a general-purpose cold-work steel designed to survive impact, misalignment, and cyclic stress while offering good wear resistance.

ASTM D6 is a specialized abrasion steel designed to survive environments where hard mineral particles would destroy normal tool steels.

If your tooling fails by cracking or chipping, D6 will make the problem worse.

If your tooling fails by edge washout, erosion, or loss of geometry, D2 will never survive long enough.

Choosing between D2 and ASTM D6 is not about brand or hardness. It is about what is attacking the tool surface—steel, or minerals.