Introduction:

Precision tooling demands high-performance steel, but importing O1 to Vietnam is a minefield. A single HS code error or a “too-good-to-be-true” supplier can turn a profitable job into a financial disaster.

This guide strips away the complexity. No fluff—just the verified steps to secure authentic O1 steel, unlock FTA duty savings, and bypass customs delays at Cat Lai or Hai Phong. You need to know your true landed cost before signing that purchase order. Here is how to get it right the first time.

O1 Tool Steel Chemical Composition & Key Benefits

You can’t just trust the label. O1 tool steel gets its performance from a specific chemical recipe. In Vietnam’s humid environment, getting this balance right is what prevents your dies from cracking or rusting prematurely. Here are the exact percentages you need to see on the Mill Test Certificate (MTC):

| Element | Composition (%) | Key Benefit |

|---|---|---|

| Carbon (C) | 0.85 – 1.00 | Provides the hardness (60-65 HRC) for sharp cutting edges. |

| Manganese (Mn) | 0.9– 1.40 | CRITICAL: Enables safe oil quenching. Low Mn (<1%) causes soft spots. |

| Chromium (Cr) | 0.40 – 0.60 | Adds depth to hardness and helps resist wear over time. |

| Tungsten (W) | 0.40 – 0.60 | Maintains a fine grain structure for better toughness. |

| Silicon (Si) | 0.20 – 0.50 | Stabilizes the steel size during heat treatment to reduce warping. |

Pay close attention to that Manganese (Mn) line. This is where suppliers cut corners. Authentic O1 must have at least 1.00% Mn. If a supplier offers you “O1” with only 0.5% Mn, walk away. That material won’t harden properly in oil, and your mold will likely distort or fail under pressure.

O1 Steel’s Performance in Vietnam

High-quality O1 tool steel gives you rare value: hard edges at manageable costs. Vietnam’s precision shops need this balance. Mold makers in Ho Chi Minh City use it. Blade producers in Hanoi rely on it. It keeps them competitive.O1’s chemical makeup shows up in your workshop results. 0.85-1.00% carbon content gets you 60-65 HRC hardness after heat treatment. So O1 gives your cutting edges longer life.

O1 Tool Steel Chemical Composition & Key Benefits

| Element | Composition (%) | Key Benefit |

| Carbon (C) | 0.85 – 1.00 | High edge retention & wear resistance for precision cutting |

| Manganese (Mn) | 0.9 – 1.4 | Increased toughness; prevents chipping during heavy impact |

| Chromium (Cr) | 0.40 – 0.60 | Deep hardening response & resistance to abrasive wear |

| Tungsten (W) | 0.40 – 0.60 | Maintains sharp cutting edges & improves secondary hardness |

| Silicon (Si) | 0.20 – 0.35 | Dimensional stability during the tempering process |

For Vietnamese machine shops, this specific blend offers a distinct advantage: machinability. O1 is easier to work with than D2 or high-speed steels. You spend less time roughing and finishing. However, always confirm the Manganese content stays above 1.00%. Cheap “O1” imposters often drop this to 0.50%, which destroys the steel’s ability to harden safely in oil.

Oil Quenching Saves Money in Vietnam

Heat treatment costs add up fast in Vietnam’s competitive market. O1’s oil quench process (780-830°C) produces minimal distortion. This matters for precision molds with tight tolerances. Water-quenched steels warp more. They need expensive secondary machining to fix the warpage. You skip those rework costs.

Tempering at 150-200°C after quenching locks in stable dimensions. At HRC 62, O1 maintains 2200 MPa compressive yield strength. Your dies run continuous stamping jobs. No early failures.

Cost Positioning for Vietnamese Buyers

O1 steel sits in a great spot on the market. You pay less than you would for premium D2. Yet, it holds a sharper edge than A2. For Vietnamese manufacturers, this balance makes sense. You get strong performance without breaking the budget.

Where It Shines:

Auto Manufacturing: Works well for high-wear cutting and punching dies. These tools handle heavy use.

Knife Production: A top pick among Hanoi makers. They rely on it for precision blades.

Mold Shops: Smart for injection molds. You can hold tight dimensions over thousands of cycles.

The Trade-Off: Rust

O1 is not stainless, but it resists corrosion better than plain carbon steel.So, you must add protective coatings. But for indoor workshops in Vietnam, you can handle this easily. You aren’t fighting outdoor weather or coastal salt spray. Take on this small maintenance task. You get top cutting performance for every dollar.

Finding the Right O1 Partner & Red Flags

Your supplier choice matters. High-quality O1 tool steel either arrives ready to work—or turns into expensive scrap metal. Vietnam’s import market has experienced steel traders and opportunistic middlemen. The difference appears on your production floor, not just your invoice.

The Four-Layer Verification System

Importing O1 steel to Vietnam requires precision, not guesswork. Skip the marketing noise—here is your practical checklist for a secure transaction:

- Verify Before Buying: Cheap quotes often mean fake alloys. Demand detailed Mill Test Certificates (MTC) and test samples locally for 60-65 HRC hardness.

- Nail the HS Codes: Misclassifying the 7228 series triggers 15-30% penalties. Get this right to bypass delays at Cat Lai or Hai Phong ports.

- Leverage FTA Benefits: Don’t pay full duty. Ensure your Certificate of Origin (Form D/E) is perfect to cut tariffs to 0-5%.

- Know Real Landed Costs: FOB prices are deceptive. Factor in CIF, VAT, and hidden port fees to see your actual margin before signing the PO.

Red Flags That Cost Vietnamese Buyers Money

- Suspiciously Low Prices: Genuine O1 steel typically costs $2,800–3,600/ton. Quotes significantly lower (e.g., $2,200) often signal fake alloys with insufficient carbon content (0.65%), leading to early tool failure and expensive production scrap.

- Vague Origin Descriptions: Avoid generic labels like “European origin.” Legitimate suppliers name the exact mill (e.g., Bohler, Daido, Crucible). Vague details often hide inferior steel from uncertified re-rollers, resulting in inconsistent hardness and ruined product batches.

- Incomplete Paperwork: Missing commercial invoices, packing lists, or accurate HS codes (7228.30/7228.60) create customs nightmares. Errors here block FTA tariff benefits and can trap your shipment at port for weeks, piling up storage fees.

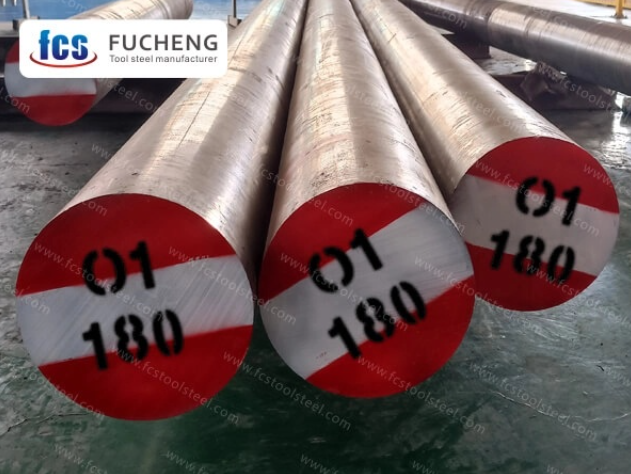

Recommended Partner: FCS Tool Steel

If you want to bypass the import risks described in this guide, consider sourcing through FCS Tool Steel. They have built a strong presence serving the Vietnamese tooling market, bridging the gap between global quality and local availability.

Why do mold makers choose them?

- Verified Quality: FCS provides full Mill Test Certificates (MTC) with every order. You don’t have to guess about carbon content or hardness—the data is right there.

- Logistics Speed: Instead of waiting weeks for customs clearance yourself, FCS manages the logistics pipeline. They deliver O1 steel that is cleared and ready for your workshop floor.

- Technical Support: They understand the specific heat treatment needs of O1 (oil quenching). Their team helps ensure you pick the right grade for your specific die or mold application.

For Vietnamese manufacturers tired of rolling the dice on “mystery steel,” FCS Tool Steel offers a secure, transparent alternative. You get the audit trail of a major importer with the service of a local partner.

Mastering Tariffs: HS Codes & FTA Savings

Tariff mistakes hurt budgets more than supplier markups. One wrong digit in your HS declaration causes 15-30% penalties. Plus, it leaves your steel stuck at Cat Lai Port. Here is how you classify O1 correctly and save tax money.

Understanding the HS 7228 Series

Vietnamese customs looks at physical form and finish. Stick to these specific codes:

Bars & Rods: We see this O1 import most often. Ground or precision-peeled O1 bars are usually cleared under 7228.60 in Vietnam. Pick 7228.30 for hot-rolled types.

Flat Products: Width matters here. Material ≥600mm fits the 7225 series. Anything <600mm goes into the 7226 series.

Rectangular Bars: Watch out for widths over 125mm. Customs often labels them as plates, which means higher duty. Declare them as 7228 bars. You must prove this with their production method.

Cut Costs with FTA Benefits

Free Trade Agreements (ATIGA, ACFTA, EVFTA) drop your duty rate. You go from 15% (MFN) to 0-5%. This saves you over $4,000 on a typical 10-ton order.

Strict compliance helps you qualify:

Valid Certificate of Origin: Use the right forms. Form D or Form E work, depending on the source country.

Exact Mill Details: Avoid generic origins like “Made in EU.” Your paperwork needs a clear trail to the specific mill. For example, list “Bohler Kapfenberg.”

Chemical Proof: Customs checks alloy content. Your Mill Test Certificate must show 0.90-1.00% Carbon and <0.6% Chromium. This proves it is real O1 tool steel.

Your Four-Step Classification Checklist

Stop guessing at HS codes. Follow this sequence before filing customs papers:

Step 1: Measure physical dimensions. Width >125mm and bar/rod form? Start with 7228 series. Flat products? Measure width against 600mm limit.

Step 2: Identify processing method. Cold-finished surfaces point to 7228.50. Hot-rolled scale texture means 7228.30. Check your mill certificate’s “condition” field.

Step 3: Verify O1 chemistry against high-speed steel limits. O1’s tungsten content (0.4-0.6%) sits below high-speed steel minimums (6%+ tungsten). This confirms NESOI tool steel class.

Step 4: Match WCO (World Customs Organization) Chapter 72 notes with your supplier’s export documents. Compare their declared HS code against Vietnam’s import tariff schedule. Gaps mean you need pre-clearance talks with licensed customs brokers.

Vietnamese customs updated HS codes align with global 2025 changes. GCC countries shifted to 12-digit codes January 1, 2025. U.S. 10-digit HTS becomes required September 1, 2025. EU refined CN Chapter 72 splits January 2025. These changes don’t alter O1’s core 7228 class but add check digits. Your customs broker handles the extended codes during declaration.

Logistics & Customs Roadmap: From Port to Factory

Your O1 tool steel shipment arrives at Vietnam’s port. The race begins. Customs clearance delays cost you $80-150 per day in storage fees. Missing paperwork triggers red-lane inspections. These last 7-14 days. Your production line waits. Workers stay idle. Clients get angry.

Smart importers move cargo from ship to factory floor in 3-7 days. They know the system. You need the same advantage.

Pre-Import Compliance: O1 Steel Pre-Import Compliance Checklist

- Legal Authority & Business Credentials

- Business License: Ensure a valid copy of your Enterprise Business License is ready.

- Tax Registration: Verify your Tax ID is active; this serves as your primary legal authorization for import.

- VNACCS System Registration (Critical Step)

- Platform Role: All declarations are processed via the Vietnam Automated Cargo and Port Consolidated System (VNACCS).

- Action Required: Log in to the online portal, upload credentials, and set up e-signature authorization.

Timeline Warning: Approval takes 3–5 working days. Register before the steel ships to avoid container demurrage charges at ports like Cat Lai.

- High-Precision Commercial Invoice Requirements

- Specific HS Codes: Explicitly state 7228.30 (hot-rolled) or 7228.50 (cold-finished).

- Technical Specs: Vague descriptions are rejected. Use: “O1 tool steel bars, annealed condition, chemical composition per ASTM A681.”

- Financial Details: Must include unit price, total CIF value (FOB + Freight + Insurance), country of origin, and clear Incoterms (e.g., CIF Hai Phong).

- Digitization & Accuracy

- PDF Formatting: All documents must be scanned as searchable PDFs.

- Data Integrity: Ensure alloy content (>0.6% Carbon/Mn) aligns with the 7228 series. Poor scan quality or mismatched chemistry data will trigger manual reviews and delays.

The Three-Lane Customs System: Green, Yellow, Red

VNACCS assigns your O1 shipment to inspection lanes. The software analyzes your declaration data. Three outcomes determine your clearance speed.

Vietnam Customs Clearance: VNACCS Three-Lane System

| Customs Lane | Classification & Risk Level | Inspection Requirements | Estimated Timeline | Key Approval Criteria |

| Green Lane | Low Risk (Instant Release) | No physical or document inspection. | 1 – 2 Business Days | HS codes match descriptions; CIF value aligns with benchmarks; clean supplier history. |

| Yellow Lane | Medium Risk (Document Review) | Screen-based review of MTC, COO, and Packing Lists. | 3 – 5 Business Days | Detailed chemical data (C, Mn, Cr) matches invoice; paperwork is complete and accurate. |

| Red Lane | High Risk (Physical Inspection) | Full container unpacking and physical verification of dimensions/markings. | 7 – 14 Business Days | Random selection (20–30%); first-time importers; vague descriptions; undervalued CIF. |

Key Strategies for Successful Clearance

- Document Accuracy: Ensure your Mill Test Certificates (MTC) include specific alloy percentages (e.g., 0.90% C, 1.50% Mn). Vietnamese customs officers prioritize chemical composition over generic trade names.

- HS Code Consistency: Never use vague descriptions like “Steel Bars.” Use specific terminology such as “O1 Tool Steel, 55-60 HRC Hardness” to avoid being flagged for Red Lane inspection.

- The “First-Timer” Buffer: If this is your first import, budget for Red Lane timelines and physical inspection fees. Once you establish a history of 3–5 compliant shipments, your probability of receiving the Green Lane status increases significantly.

- Post-Inspection Payment: Once cleared, pay your import duties and 10% VAT via bank transfer through VNACCS to trigger the e-Delivery Order (e-DO) for port pickup.

Port Selection: Matching Location to Your Factory

Vietnam operates three major southern ports handling containerized O1 tool steel imports. Choose based on your factory location and shipment volume.Choosing the right entry point affects your inland trucking costs and clearance speed. Here is how Vietnam’s key ports compare for tool steel logistics.

| Port Name (Region) | Capacity & Key Feature | Est. Cost (20ft Container) | Best Use Case |

|---|---|---|---|

| Cat Lai (South) | 9.5M TEUs (Busiest). Direct link to HCMC industrial zones. | $1,800 – $2,200 | Frequent, small shipments (2-5 tons) to Binh Duong or Dong Nai. |

| Cai Mep (South) | Deep-water berths for large vessels (8,000+ TEU). | $1,600 – $2,000 | Bulk orders (10+ tons). Lower port fees offset the longer 80km trucking distance. |

| Vung Tau (South) | Lower congestion; fast transit to southeastern provinces. | $1,700 – $2,100 | Time-sensitive delivery to Long An or Tay Ninh factories. |

| Hai Phong (North) | Major northern hub feeding Hanoi/Bac Ninh clusters. | Matches Southern Rates | Northern factories. Sea freight takes 20-25 days from East Asia. |

For factories in VSIP I/II (Binh Duong), Cat Lai is standard, but considering the 2026 HCMC Ring Road 3 construction, Cai Mep might offer fewer traffic delays for bulk O1 orders.”

Air Freight for Urgent O1 Tool Steel Needs

Production emergencies demand speed. Sea shipping takes 20-40 days from Asian mills to Vietnam. Air freight delivers in 1-3 days. This option makes sense for small batches under 2 tons. Your downtime costs must exceed transport premiums.

| Airport (Region) | Est. Air Rate (Japan/Korea Origin) | Total Landed Cost Example (500kg) | Best Use Case |

|---|---|---|---|

| Noi Bai (HAN) – North | $8.00 – $12.00 / kg | $4,410 – $6,570 (Freight + Clearance + Handling + Trucking) |

Emergency repairs for factories in Bac Ninh or Hanoi. |

| Da Nang (DAD) – Central | $9.00 – $13.00 / kg | Similar to HAN rates | Urgent die maintenance for Central Vietnam manufacturers. |

Packaging That Passes Customs Checks

Vietnamese customs officers look closely at your packaging. Bad packing causes rusty steel. You get rejected shipments. Stick to this 3-step plan:

- Inner Protection (VCI Paper): Wrap each bar in VCI (Vapor Corrosion Inhibitor) paper. Never skip this. O1 steel has low chromium. It rusts fast in tropical humidity. Standard oil won’t last a 45-day sea trip. VCI keeps it safe for 12-18 months.

- Crate Weight Limit (2 Tons): Pack items in steel-reinforced wooden crates. Keep the total weight under 2 tons per unit. Why? Vietnam’s port forklifts handle this weight best. Go over the limit, and you need special cranes. That jumps your cost from $50 up to $180 for every move.

- Container Optimization: Keep crate length under 5.8 meters. They fit right into standard 20-foot containers (inner length: 5.9m). This prevents jams. Plus, you avoid paying extra for open-top containers.

Total Landed Cost Breakdown To Vietnam

Your true expense starts with the CIF price formula: CIF = FOB Price + International Freight + Insurance. This three-part foundation drives what customs officers calculate next. Vietnamese buyers importing high-quality O1 tool steel from China face FOB prices around $600/mt in 2025. This sits 10-20% above standard HRC benchmark rates ($500-550/mt). O1’s specialized alloy content explains the premium.

Cost Breakdown: Importing 10 Metric Tons of O1 Tool Steel

Let’s crunch the numbers for a shipment from Shanghai to Ho Chi Minh City. We’re talking 10 metric tons of real O1 rounds for precision die work.

Note: We use a real FOB price of $3,000/MT. This reflects genuine alloy content, not the $1600/MT cost of cheap construction steel.

1. CIF Cost Foundation

This sets the tax base for customs.

| Cost Element | Unit Cost (USD/MT) | Total (10 MT) |

|---|---|---|

| FOB Shanghai (Material) | $3,000.00 | $30,000.00 |

| Ocean Freight (20ft FCL) | $150.00 | $1,500.00 |

| Marine Insurance | $15.00 | $150.00 |

| CIF Value (Tax Base) | $3,165.00 | $31,650.00 |

2. Tax & Duty Liability

We use the standard 15% MFN duty rate (assuming no FTA) to show the maximum risk.

| Levy Type | Calculation | Total Payable |

|---|---|---|

| Import Duty (15%) | 15% of CIF | $4,747.50 |

| VAT (10%) | 10% of (CIF + Duty) | $3,639.75 |

| Total Taxes | — | $8,387.25 |

3. Final Landed Cost Summary

| Summary Item | Cost per MT | Project Total |

|---|---|---|

| Total CIF (Goods) | $3,165.00 | $31,650.00 |

| Taxes & Clearance | $850.00 | $8,500.00 |

| FINAL LANDED COST | $4,015.00 | $40,150.00 |

Conclusion

Quit guessing. You have the plan. Use verified suppliers. Get the right HS 7228 codes. Take advantage of FTA savings.

Hidden costs drain profits. Don’t let that happen. Act now.Ask three suppliers for mill test certificates. Then, figure out your real landed cost. Do this before you sign a deal.Precision tooling needs smart sourcing. Secure your O1 steel edge today.