1. SKD61 Chemical Composition & Functions

| Element | Content (%) | Function |

|---|---|---|

| C | 0.32–0.45 | Hardness, toughness balance |

| Cr | 4.75–5.50 | Hardenability, heat & wear resistance, corrosion protection |

| Mo | 1.10–1.75 | Heat strength, wear resistance, prevents softening at high temps |

| V | 0.80–1.20 | Wear & toughness, carbide stabilization |

| Si | 0.80–1.20 | Strength, hardness |

| Mn | 0.20–0.50 | Hardenability, reduces brittleness |

| P | ≤0.03 | Reduces brittleness |

| S | ≤0.03 | Prevents hot-shortness |

| Ni | ≤0.30 | Toughness, dimensional stability |

| Cu | ≤0.25 | Stability, corrosion resistance |

2. Key Performance Characteristics

2.1 High Temperature Strength

SKD61 tool steel stays hard even when die surfaces hit 500°C during continuous use. Molybdenum and vanadium carbides lock in strength. This stops heat damage that ruins cheaper steels. Hardness holds steady at 45–52 HRC through repeated heating and cooling. The material keeps its edge under long-term stress and heat.

Thermal fatigue resistance shines in die-casting work. The steel fights hot cracks and wear at the same time. Surface temps swing wild—from room temperature to over 600°C. Dimensional stability stays solid. Warped dies kill production tolerances and boost scrap rates.

Heat treatment brings out peak high-temp performance. Quench the steel at 1020–1050°C. Then run triple tempering cycles between 550–680°C. This cleans up the carbide network and eases internal stress. Mold life jumps more than 50% versus single-tempered parts. The steel holds together where other materials crack. You get dependable service across the 0–500°C range. No strength loss. No heavy wear.

2.2 Wear Resistance

Fine carbides spread through SKD61’s structure. This network protects surfaces from wear during forming and tooling. Vanadium and molybdenum carbides create hard barriers. They stop material loss. You get solid protection in cold dies or at 500°C in non-stop service.

SKD61 combines wear resistance with real toughness—impact values hit ≥47 J/cm². Dies resist cracking under repeated heat shocks and heavy loads. The steel won’t chip or break during high-volume production stress. Hardness holds at 45–52 HRC through temperature changes. Structure stays firm. No softening at high temps. This means steady performance across the full 0–500°C service range.

2.3 Resistance to Thermal Fatigue and Hot Cracking

Dies face repeated heating and cooling. This pushes them to their breaking point. SKD61 fights back with a microstructure built to resist cracks. Chromium (4.75–5.50%), molybdenum (1.10–1.75%), and vanadium (0.80–1.20%) lock the structure in place during thermal cycling. These elements stop cracks before they start.

Fine, well-distributed carbides spread through the martensitic matrix. This network blocks crack growth when temps swing fast. The steel absorbs thermal shock without splitting. Impact values ≥47 J/cm² prove the material handles sudden stress. Your dies survive violent temperature changes from casting and forging work.

Hot cracking stays away thanks to excellent dimensional stability. Thermal expansion measures just 16–17 × 10⁻⁶/K. Dies hold their shape through endless heat cycles. Thermal conductivity hits 42.7 W/m·K at 100°C. Heat flows out fast. This cuts dangerous temperature gaps that crack weaker steels.

Triple tempering at 550–680°C after quenching transforms the structure. Grain size stays fine and moderate. Carbides spread throughout. This process boosts mold life over 50% versus basic heat treatment. Aluminum die-casting dies run longer. So do hot extrusion tooling and forging equipment. SKD61 outlasts competing tool steels where thermal fatigue destroys performance.

2.4 Resistance to Softening at High Temperatures

SKD61’s carbide network locks in hardness at high operating temperatures. The steel keeps its structure intact through long hot work cycles. Fine carbides spread evenly through the matrix stop thermal softening that ruins weaker tool steels.

Tempering temperature controls final hardness. At 540°C, the steel holds 52 HRC. Raise tempering to 550°C, and hardness drops to 50 HRC. Push it to 565°C, and you get 48 HRC. At 580°C, hardness settles at 44 HRC. This controlled drop lets you set exact hardness for specific die jobs.

The material performs well across the 0–500°C service range. Hot work dies face constant heat stress. SKD61 resists softening, so dies keep their cutting edges and surface hardness. Production runs stay the same. Tool life goes far beyond standard grades that lose hardness under heat.

2.5 Good Hardenability

SKD61 gives you uniform hardness through the entire tool cross-section. The core and surface stay equally hard, even in large, complex dies. Chromium (4.75–5.50%) and manganese (0.20–0.50%) create this balance. These two elements push hardening deeper during quenching.

Deep-hardening performance matters in thick die blocks. The steel hardens from surface to core without variation. Soft spots don’t form inside. This prevents uneven wear and weak spots during high-load hot work. Your tools keep the same strength throughout. Performance stays reliable across the full cross-section.

Uniform hardness means longer tool life. Dies resist bending and wear at the same rate everywhere. Production quality holds steady through long runs. SKD61’s hardenability fits tough hot-work jobs where tool size and complexity would break lesser grades.

2.6 Good Toughness

SKD61 tool steel won’t crack under pressure. Charpy impact values stay above 47 J/cm²—way past minimum industrial standards. This toughness comes from a fine grain structure packed with small, evenly-spread carbides. The structure absorbs shock and stops cracks from spreading.

Dies take a beating—sudden hits, heat shocks, and heavy loads. SKD61’s balanced properties cut crack risk to nearly zero. The steel bends instead of breaking. Your tools survive high-volume production without breaking down.

3. Mechanical Properties

| Property | Typical Value / Range | Notes |

|---|---|---|

| Hardness (HRC) | 40–52 | Most dies 42–48 HRC; higher = wear resistance, lower = impact resistance |

| Brinell Hardness (HB) | 207–335 | Soft annealed for machining; hardened after quenching/tempering |

| Tensile Strength (Rm) | 1200–1590 MPa | Higher tempering → lower strength, higher toughness |

| Yield Strength (Rp0.2) | 1000–1380 MPa | Lower tempering → higher yield, higher tempering → more toughness |

| Elastic Modulus | 207 GPa | Stable under heat ≤500°C |

| Poisson’s Ratio | 0.27–0.30 | Lateral contraction under tension |

| Elongation (A%) | 9–15% | Higher tempering → more ductility |

| Cross Section Reduction (Z%) | 50–53% | Shows plastic deformation capacity |

| Impact Toughness (Charpy) | 13.57–24.44 J | Higher tempering → higher toughness, lower hardness |

| Specific Heat Capacity | 460–500 J/kg·K | Controls heating/cooling behavior |

4. Machinability & Processing Performance

| Property / Process | Performance / Notes |

|---|---|

| Machinability | 65–70% vs standard tool steels; easier after annealing (207 HB) |

| Deep Hole Drilling | Up to 9.8 m for internal cooling channels |

| Heat Treatment | Quench 1020–1050°C, triple temper 550–680°C for peak strength |

| Annealed Hardness | 207 HB for easy pre-machining |

| Polishing | Achieves mirror finish on dies |

| Production Forms | Plate, sheet, coil, flat bar, round bar, strip, wire, forgings |

5. Applications

| Application | Details / Industries |

|---|---|

| Die Casting Dies | Aluminum & non-ferrous metals, withstand 600°C |

| Hot Extrusion Dies | Aluminum profiles, maintains shape under heat & pressure |

| Forging Dies | Absorbs hammer blows & thermal stress |

| Bolt Heading Dies | Forms fasteners under repeated loads |

| Hot Shearing Blades | Cuts heated metal bars cleanly |

| Mandrels & Punches | Hot-forming tools, stable dimensions & wear resistance |

| Industries | Automotive, aerospace, heavy manufacturing, general hot-work tooling |

6. SKD61: The Leading Steel for General Hot Working and Forging Molds

General Hot Working and Forging Molds

SKD61 leads hot work tooling worldwide. Its fine, evenly spread carbides give you strong toughness and stable dimensions. Complex dies keep their accuracy under heavy production loads. Large forging molds won’t warp during heat cycles. The martensitic structure forms after quenching and tempering, creating a fine grain base that handles tough hot work jobs without breaking.

Vacuum degassing and electric slag remelting clean the steel before it reaches your shop. High purity means fewer flaws. You get steady performance across production batches. Dies last longer. Scrap rates drop. SKD61 is the top pick for general hot working and forging molds. Automotive, aerospace, and heavy manufacturing plants rely on it.

6.1 SKD61 Hardness vs Tempering Temperature

| Tempering Temperature (°C) | Hardness (HRC) | Impact Toughness (J) | Notes |

|---|---|---|---|

| 540 | 52 | 13.57 | Maximum surface wear resistance, lower toughness |

| 550 | 50 | – | Moderate hardness, balance wear and toughness |

| 565 | 48 | 24.44 | Balanced hardness and impact toughness |

| 580 | 44 | – | Lower hardness, higher toughness |

| 620 | 45 | High | Suitable for extrusion dies and die casting inserts |

6.2 SKD61 Standard Heat Treatment Process

| Step | Temperature (°C) | Duration / Notes | Purpose |

|---|---|---|---|

| Preheat | 600–850 | – | Prevent thermal shock |

| Austenitizing | 1000–1050 | Hold for uniform heating | Full austenitic transformation |

| Quenching | – | Air, oil, or polymer depending on section | Hardening |

| Tempering | 500–650 | Triple cycle, ~2h per cycle | Refine carbide network, reduce internal stress |

| Annealing (Softening) | 840–860 | 2–4 hours, slow cooling 30–50°C/h | Improve machinability, reduce stress |

6.3 SKD61 Machinability and Annealed Properties

| Property | Value | Notes |

|---|---|---|

| Hardness (annealed) | 170–207 HB | Soft state for easier machining |

| Machinability | 65–70% of W1 steel | Turning, milling, drilling improved |

| Carbide Structure | Small, round carbides in ferrite | Uniform cutting, better heat treatment results |

| Cooling Rate | 30–50°C per hour to 500°C, then air cool | Prevents internal stress |

7. Product Features / Additional Characteristics

SKD61 meets global standards—JIS SKD61, AISI H13, and DIN 1.2344. This means worldwide compatibility and reliable sourcing. The density of 7.7–8.03 × 10³ kg/m³ helps you calculate die weight accurately. You need this for press setups and handling equipment. Melting temperature sits at 1370–1400°C. That’s far above service conditions. Your structure won’t break down during extreme heat.

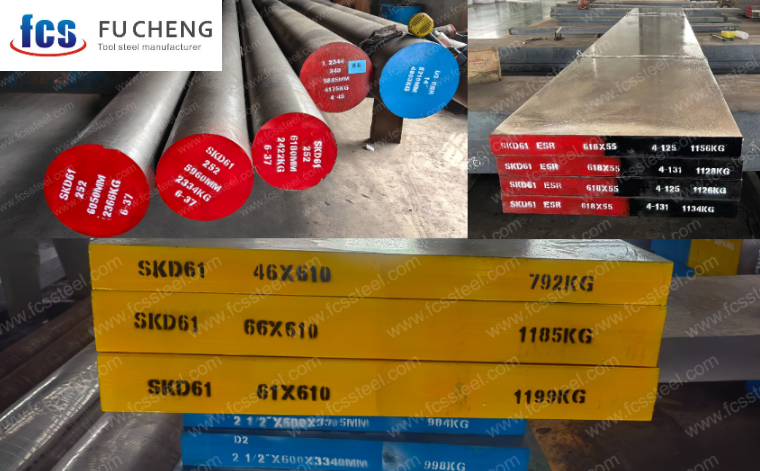

Electrical resistivity measures 0.7 Ω·mm²/m. This value stays stable for industrial uses where electromagnetic properties count. The steel ships in multiple product forms—plate, sheet, coil, flat bar, round bar, strip, wire, and forgings. You get what fits your manufacturing needs. No custom orders required.

Dimensional ranges cover most die sizes: Round bars span 1–2000 mm diameter. Square bars run 10–1000 mm. Plates and sheets offer 0.08–800 mm thickness with 10–1500 mm width. Tubing comes in OD φ4–410 mm with wall thickness 1–35 mm. This range cuts material waste. You won’t deal with oversized blanks.

Strong thermal fatigue resistance sets SKD61 apart from lower-alloy hot work grades. Other steels crack faster under repeated heating and cooling. SKD61 lasts longer in die casting, extrusion, and forging. Surface temperatures swing between shots in these processes.

8. Corrosion Resistance

Chromium levels at 4.75–5.50% protect SKD61 from oxidation during hot work. A thin oxide film forms on die surfaces. This layer blocks attacks from molten aluminum, magnesium, zinc, and copper alloys.

Die casting puts tooling under chemical stress. Plus, temperatures change fast. SKD61 handles both. You won’t see the surface damage that ruins cheaper steels.