What Is X40CrMoV5-1 Tool Steel?

Why do some die casting molds fail after just a few thousand cycles? Others keep running past 100,000 cycles. I’ve seen the difference comes down to one thing: the steel.

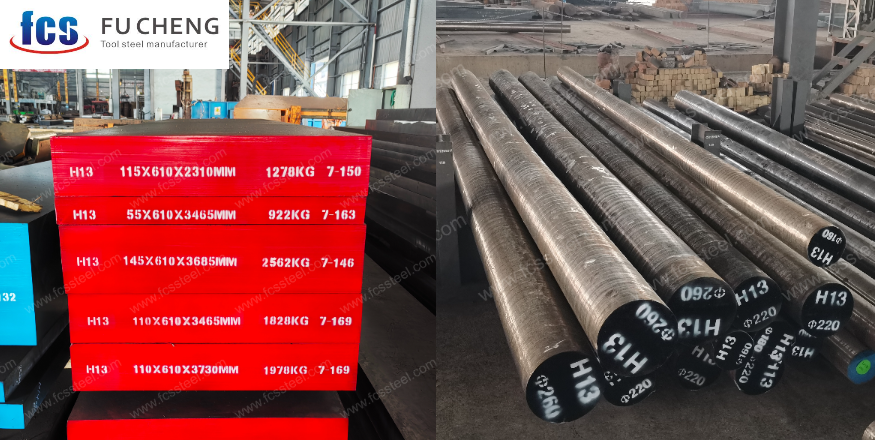

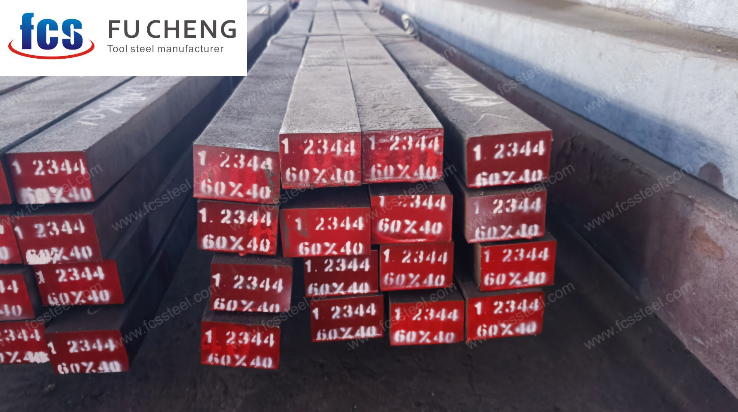

Let me tell you about X40CrMoV5-1 tool steel. X40CrMoV5-1 tool steel is a high-performance hot work steel. It belongs to the chromium-molybdenum-vanadium alloy group. You may also know it by other names like H13, 1.2344, and SKD61. Many industries use this steel for tough jobs.

Equivalent Standards & Nomenclature

X40CrMoV5-1 tool steel has many equivalent names around the world. Different countries use different standards. But the chemical makeup and performance are very similar. If you need to buy or specify this steel, you must know these equivalents. This helps you get the right material and ensures your tools work well.

International Standard Equivalents for X40CrMoV5-1

| Country/Region | Standard | Grade/Designation |

|---|---|---|

| Europe | EN ISO 4957 | X40CrMoV5-1 (1.2344) |

| USA | ASTM A681 | H13 |

| Germany | DIN W-Nr 17350 | 1.2344 |

| Japan | JIS G4401 | SKD61 |

| China | GB/T 9943-2008 | 4Cr5MoSiV1 |

| UK | BS 4659 | BH13 |

These standards appear often in supply chains and technical documents. In North America and Asia, you’ll see H13 most often. SKD61 is the common name in Japan. In Germany and Europe, people use 1.2344.

Quick Reference Table: X40CrMoV5-1 Chemical Composition

| Element | Typical Content (%) |

|---|---|

| C | 0.35–0.42 |

| Si | 0.80–1.20 |

| Mn | 0.25–0.50 |

| P | ≤0.030 |

| S | ≤0.020 |

| Cr | 4.80–5.50 |

| Mo | 1.20–1.50 |

| V | 0.85–1.15 |

This optimized chemical formula makes X40CrMoV5-1 tool steel stand out. It resists deformation well. It maintains high hardness during repeated heating and cooling. It keeps excellent toughness and size stability even under severe hot work conditions. Based on my experience, I suggest this steel for any demanding tooling application.

Key Properties of X40CrMoV5-1 Tool Steel

1. Abrasion Resistance and Toughness

- Good abrasion resistance works at both low and high temperatures. The steel’s balanced alloying elements ensure this.

- High toughness: After hardening and tempering, it achieves Charpy V-notch impact values from 16 J at 527°C up to 30 J at 605°C. The steel withstands industrial stress and shocks during forging or die casting.

2. Red Hardness and Thermal Fatigue Resistance

- It maintains excellent red hardness. The working hardness stays between 50–56 HRC even after repeated heat treatments.

- Thermal fatigue resistance and thermal shock resistance are strong. X40CrMoV5-1 performs well in applications exposed to heating and cooling cycles. This reduces the risk of heat checking or tool failure.

3. Thermal Conductivity and Specific Heat

- Thermal conductivity: from 19.2 W/(m·K) at room temperature up to 26.1 W/(m·K) at 600°C

- Specific heat capacity: increases from 460 J/(kg·K) to 587 J/(kg·K) over the same temperature range

- These heat flow properties are crucial for tools. They must dissipate heat quickly to avoid distortion or thermal damage.

4. Use-Case-Driven Property Expectations

- Hot forging, die casting, and extrusion dies benefit from the steel’s ability to keep >50 HRC and high toughness at elevated temperature.

- Consistent resistance to thermal fatigue and high strength during cyclic loading ensure long mold and die service life.

- Machinability is excellent in the annealed state. This is due to uniform microstructure and a low delivery hardness of max 229 HBW.

Mechanical Properties (Typical Values) of X40CrMoV5-1 Tool Steel

X40CrMoV5-1 tool steel offers strong mechanical performance in many operating conditions. Below, I break down the key mechanical properties. I’ll explain what they mean for hot work tool steel applications.

1. Core Mechanical Strength Data

- Tensile strength (Rm) at room temperature: 1495–1960 MPa

This high tensile strength means the steel can bear heavy loads before breaking. - Yield strength (Rp0.2) at room temperature: 1290–1570 MPa

I recommend this steel for applications needing dimensional stability. It resists deformation well. - Elongation: 13.0–15.4%

This balances strength and ductility. The steel can stretch a bit before fracture. - Reduction of area: 46.2–54.0%

This shows strong plasticity. I find this important for tools under repeated stress. - Charpy impact value (KV): 16–30 J

This reflects good impact toughness. The steel maintains this even after high-temperature tempering.

2. Hardness and Heat Treatment

- Hardness after tempering (527–605°C): 44–52 HRC

This provides solid working hardness for typical hot work tooling. - Working hardness range: 50–56 HRC

This range resists wear and deformation during heavy cycles. - Brinell hardness (soft/annealed): max 229 HB

This allows easy machining and shaping before final heat treatment.

3. Mechanical Highlights

- The steel keeps high tensile and yield strengths even after tempering. This is critical for high-volume or high-temperature manufacturing.

- Charpy impact values up to 30 J show real-world toughness. This minimizes tool breakage.

- Working hardness between 50–56 HRC supports extended tool life.

- Properties change with heat treatment. Always match the tempering cycle to exact tooling needs.

- Based on my experience: For mission-critical molds or dies, review the tempering data with your supplier. This will optimize longevity and reliability.

Applications of X40CrMoV5-1 Tool Steel

I recommend X40CrMoV5-1 tool steel for hot work tooling applications. It offers exceptional toughness, red hardness, and wear resistance. Based on my experience, this material delivers reliable performance in demanding environments.

Common Industrial Applications

- Extrusion Tools:

This steel is used for making dies, liners, mandrels, pressure pads, followers, bolsters, die holders, and adaptor rings in aluminum and brass extrusion. I suggest it as the primary material for die inserts. It works well for manufacturing aluminum profiles in construction and automotive sectors. - Forging Dies:

I like X40CrMoV5-1 for hot forming and die forging of automotive and industrial parts. It endures repeated heating cycles. It keeps its strength during heavy-duty forging operations. - Pressure Die-Casting:

This steel is essential for casting dies of aluminum, magnesium, and zinc alloys. We see it often in automotive housings, engine blocks, and consumer electronics casings. It serves as the material for die holders and die cases. It delivers long life and reduces downtime from cracking. - Press Dies and Shear Blades:

I recommend this steel for hot shear knives and swaging dies that face high thermal and mechanical stress. In steel mills and foundries, shear blades made from this material cut red-hot bars and billets with precision. - Ejector Pins & Die Systems:

We use it in ejector systems. It has strong resistance to wear and thermal cycling. This keeps precision dies operational for longer production runs. - Plastic and Light Alloy Processing:

Its thermal conductivity and toughness make it effective for injection and compression molds. I suggest it for reinforced plastics and abrasive thermoplastics in automotive and consumer goods industries.

Advantages and Features of X40CrMoV5-1 Tool Steel

X40CrMoV5-1 tool steel works well in tough industrial settings. I recommend it for hot work tooling. Its alloy mix and how it’s made give it strong mechanical and physical properties.

1. High-Temperature Strength and Performance

- Keeps working hardness above 40 HRC at 600 °C. Even at extreme heat, it holds more than 85% of its hardness.

- Beats standard mold steels in high-temperature strength. It stays stable through repeated heating and cooling cycles.

- Perfect for die casting and forging. Tools face constant heating and cooling in these jobs.

2. Toughness and Dimensional Stability

- After heat treatment, you get 50–54 HRC hardness and impact toughness of 25–30 J/cm².

- Heat treatment causes very little warping. This makes it great for complex or precision molds.

- Stays accurate under stress. Based on my experience, this extends tool and mold life.

3. Wear, Abrasion, and Fatigue Resistance

- The alloy design (5% Cr, 1.3% Mo, 1% V) gives excellent abrasion resistance. It beats H13 steel in similar uses.

- Resists thermal fatigue and cracking well. It also fights erosion from molten aluminum and copper alloys.

- Case data shows 30–40% longer service life in aluminum die-casting molds versus standard H13 steel. This cuts down on maintenance and tool changes.

4. Surface Treatability and Longer Life

- Nitriding treatments push surface hardness to HV 1000–1200+. This improves wear life under tough conditions.

- ESR (Electro-Slag Remelted) grades are very clean inside. After polishing, surface roughness can hit Ra 0.05 μm or less. I find this crucial for high-finish molds and fine detail work.

5. Corrosion Resistance and Surface Durability

- 5% chromium content protects tools from molten metals, cooling fluids, and harsh plastics.

- Surface treatments boost acid and chemical resistance for special uses.

6. Versatility and International Compatibility

- Covers many uses: die-casting molds, extrusion dies, hot forging dies, shear blades, thick wall plastic molds, and more.

- Available worldwide under different standards (ASTM H13, DIN 1.2344, JIS SKD61, etc.). This makes sourcing and replacement easy in all major markets.

7. Machinability and Production Efficiency

- As-supplied annealed bars have ≤235 HBS hardness. This allows for precise machining.

- Pre-hardened grades (28–32 HRC) are ready to use. They shorten manufacturing time and make tooling prep simpler.

- Works for both small, complex precision parts and large industrial tooling.

8. Key Figures and Competitive Data

- Alloy composition: 5% Cr, 1.3% Mo, 1% V

- Hardness after heat treatment: up to 50–54 HRC

- Surface hardness after nitriding: HV 1000–1200+

- Impact energy: 25–30 J/cm²

- High-temperature strength retention: >85% at 600 °C

- Service life extension: 30–40% longer compared to H13 in aluminum die casting

- Surface finish (ESR): Ra 0.05 μm or better

Conclusion

I’ve worked with hundreds of tool steels throughout my career, and X40CrMoV5-1 consistently stands out. Whether you’re running high-volume die casting or precision extrusion work, this steel delivers when it matters most. The combination of heat resistance, toughness, and long service life makes it worth every penny. If you’re serious about reducing downtime and maximizing your tooling investment, I believe this is the steel you should choose.