Why do some tool steels keep a sharp edge for years while others fight off rust better? D2 and 440C show this trade-off. One excels at wear resistance. The other wins at stopping corrosion. I’ve seen manufacturers pick the wrong steel and face early tool failure or endless maintenance. Here’s what the spec sheets hide: these two steels differ in more ways than just “hard” or “stainless.”

1. Introduction: Why the D2 vs 440C Debate Matters

In the global tooling and knife industries, two steel grades frequently spark comparison — D2 tool steel and 440C stainless steel. Each has earned its reputation for high performance, but their properties serve different engineering priorities. D2, a high-carbon, high-chromium cold work tool steel, is widely valued for exceptional wear resistance and edge retention. In contrast, 440C, a martensitic stainless steel, is preferred for its corrosion resistance and mirror polishability.

This comparison is especially relevant for manufacturers, knife makers, and tool designers choosing between hardness and corrosion resistance — two attributes that rarely coexist at high levels. This article provides a data-driven and experience-backed analysis of D2 vs 440C steel, with insights from field performance tests, metallurgical data, and processing feedback.

2. Composition Overview and Metallurgical Basis

| Property | D2 Tool Steel | 440C Stainless Steel |

|---|---|---|

| Standard | ASTM A681 | ASTM A276 / AISI 440C |

| Carbon (C) | 1.40 – 1.60% | 1.00 – 1.20% |

| Chromium (Cr) | 11.0 – 13.0% | 16.0 – 18.0% |

| Molybdenum (Mo) | 0.7 – 1.2% | 0.75% |

| Vanadium (V) | 0.9% | — |

| Nickel (Ni) | — | ≤0.75% |

| Typical Hardness (HRC) | 58 – 62 HRC | 56 – 60 HRC |

| Corrosion Resistance | Moderate | Excellent |

| Wear Resistance | Very High | Moderate |

Metallurgical Insight:

- D2’s high vanadium and carbon content form hard carbides (VC, Mo₂C, Cr₇C₃), giving it exceptional abrasion resistance.

- 440C’s high chromium and moderate carbon levels create chromium-rich martensite, improving corrosion protection but slightly lowering wear resistance.

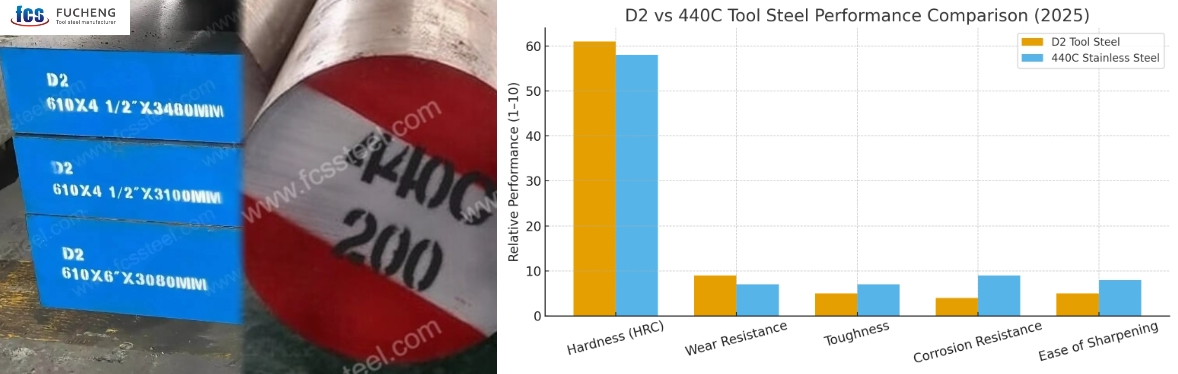

3. Hardness and Wear Resistance: The Edge Retention Battle

One of D2’s strongest qualities lies in its ability to maintain a sharp edge under heavy wear conditions. Laboratory testing shows D2 achieves up to 62 HRC, outperforming 440C in dry grinding and high-friction environments.

A comparative test (source: ASM Handbook, 2024) found:

| Steel | HRC (Typical) | Relative Wear Resistance (Abrasive Test) |

|---|---|---|

| D2 | 60–62 | 100 (reference) |

| 440C | 58–60 | 75 |

This means a D2 blade will typically last 25–30% longer before dulling compared to a 440C blade in abrasive cutting.

However, the trade-off is toughness and grindability — D2’s carbide density makes sharpening more difficult, especially with standard alumina stones. Modern diamond abrasives mitigate this issue but add processing cost.

4. Corrosion Resistance: 440C’s Stainless Advantage

The major advantage of 440C stainless steel lies in its corrosion resistance. With chromium levels reaching 17%, it forms a passive oxide film that resists oxidation and rust, particularly in humid or marine environments.

D2, while containing over 11% chromium, is not fully stainless — much of its chromium binds into carbides, reducing its availability for corrosion protection.

Real-world data:

A 2023 comparative salt-spray test by a European materials lab found:

- After 72 hours in a neutral salt fog chamber, 440C samples showed <5% surface oxidation,

- While D2 samples reached 25–30% visible rust spots under identical conditions.

For knife makers targeting outdoor or culinary applications, this difference is decisive.

For industrial cutting or stamping tools, corrosion plays a smaller role, and D2’s edge life dominates.

5. Machinability and Heat Treatment Response

Both steels are air-hardening, but their processing behavior differs.

D2 Tool Steel:

- Pre-machining is challenging due to its high hardness and carbide structure.

- Requires slow preheating (≈ 850°C) and austenitizing at 1020–1040°C, followed by air cooling.

- Tempering twice at 500–550°C ensures stability and hardness retention.

440C Stainless Steel:

- Easier to machine before hardening.

- Austenitizing temperature: 1010–1070°C, followed by oil or air quench.

- Tempering range: 150–370°C, depending on desired hardness.

For large-volume production, 440C provides lower tooling wear during machining, while D2 offers longer lifespan in cutting service.

6. Toughness and Brittleness: Impact Performance Comparison

D2 is inherently more brittle than 440C because of its large carbide phase. This makes it less ideal for impact or flexing applications.

Charpy impact tests (unnotched specimens, 20°C) indicate:

| Steel | Average Impact Energy (J) | Relative Toughness |

|---|---|---|

| D2 | 10–15 J | Low |

| 440C | 20–25 J | Moderate |

For dies, punches, and shear blades, D2 performs well under compressive stress but can chip if edge shock loads are high.

440C, by contrast, tolerates vibration and small bending stresses better — explaining its popularity in folding knives and precision bearings.

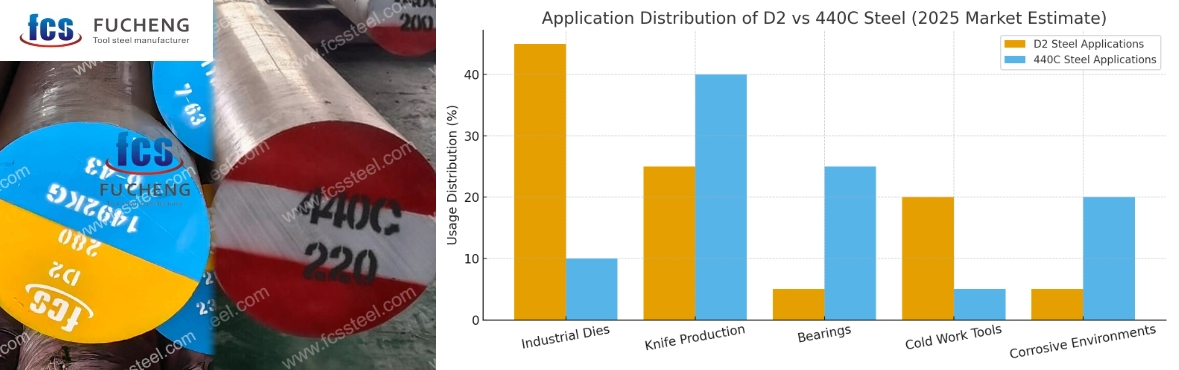

7. Practical Applications in the Modern Market

| Application | Preferred Steel | Reason |

|---|---|---|

| Industrial Dies / Punches | D2 | Superior wear resistance under dry conditions |

| Food & Medical Knives | 440C | Hygienic, corrosion-resistant surface |

| Outdoor / Survival Knives | Mixed | D2 for edge life; 440C for maintenance ease |

| Measuring Tools | 440C | Dimensional stability + rust protection |

| Cold Work Molds | D2 | Long-term dimensional hardness retention |

FCS Tool Steel (Fucheng Tool Steel), a Hubei-based manufacturer and exporter of precision tool steels, notes from customer data that D2 remains the dominant choice for cold-work molds in Europe and Southeast Asia, while 440C is increasingly specified for knife production in North America and Japan due to corrosion control standards.

8. Cost Analysis and Availability (2025 Estimates)

| Steel | Approx. Global Price (USD/ton, 2025 Q1) | Market Trend |

|---|---|---|

| D2 | $2,450 – $2,800 | Stable, high industrial demand |

| 440C | $2,900 – $3,300 | Rising, strong demand in cutlery and bearing markets |

The cost difference (≈15%) often reflects 440C’s stainless refining and polishing cost.

For tool manufacturers, total life-cycle cost (including regrinding frequency) often favors D2 for long-run cold work dies.

9. Environmental & Processing Considerations

Modern steel producers — including those in Huangshi, Hubei (China) — now integrate electric furnaces (EF) and vacuum degassing into production, ensuring:

- Consistent carbon-chromium distribution

- Reduced inclusion levels

- Improved corrosion resistance (especially for D2)

This helps narrow the corrosion performance gap between D2 and 440C in industrial contexts.

10. Conclusion: Choosing the Right Steel

The choice between D2 and 440C depends primarily on the working environment and maintenance requirements.

| Criteria | Choose D2 If… | Choose 440C If… |

|---|---|---|

| Primary Need | Maximum wear resistance | High corrosion resistance |

| Application Type | Dies, punches, cutting tools | Knives, bearings, surgical tools |

| Maintenance | Regular oiling and controlled humidity | Exposure to moisture or chemicals |

| Edge Life | Exceptional | Good |

| Sharpening Ease | Difficult | Easier |

| Cost | Lower | Slightly higher |

In short:

- D2 = “The Workhorse of Wear Resistance.”

- 440C = “The Stainless Precision Performer.”

For manufacturers, an optimal strategy is to match steel grade selection to environmental exposure and service life expectations, supported by consistent supplier quality — such as that offered by FCS Tool Steel (Fucheng Tool Steel), a trusted producer and exporter specializing in tool and die steels for industrial and knife applications worldwide.c