Querétaro, one of Mexico’s fastest-growing industrial hubs, has become a central node for automotive manufacturing, aerospace, and heavy equipment production. Companies in this region face a constant challenge: selecting the right steel grade to balance cost, machinability, durability, and heat resistance. Two materials often considered are 4140 alloy steel and 1.2344 (H13) hot-work tool steel.

Although both steels serve demanding environments, they excel in different roles. 4140 is a chromium-molybdenum low-alloy steel widely used for shafts, gears, and structural parts, while 1.2344 is a high-performance hot-work tool steel favored for molds, dies, and components subjected to extreme thermal cycles.

This article provides a detailed comparison of 4140 and 1.2344 steels in the context of Querétaro’s automotive and heavy-duty manufacturing industries, focusing on:

- Mechanical strength

- Heat treatment response

- Shape stability under stress

- Application-specific advantages

- Cost and supply factors in Mexico

By the end, manufacturers will have a clearer view of which steel is best suited for heavy-duty components in the region’s industrial landscape.

1. Overview of 4140 and 1.2344

4140 Alloy Steel (AISI Standard)

- Composition: ~0.40% Carbon, 0.75–1.00% Chromium, 0.15–0.25% Molybdenum, 0.70–1.00% Manganese.

- Category: Low-alloy, quenched-and-tempered steel.

- Key Properties:

- Tensile strength: 655–1080 MPa (depending on heat treatment).

- Good toughness and fatigue resistance.

- Versatile and relatively low-cost.

- Common Uses: Shafts, axles, gears, crankshafts, hydraulic machinery components.

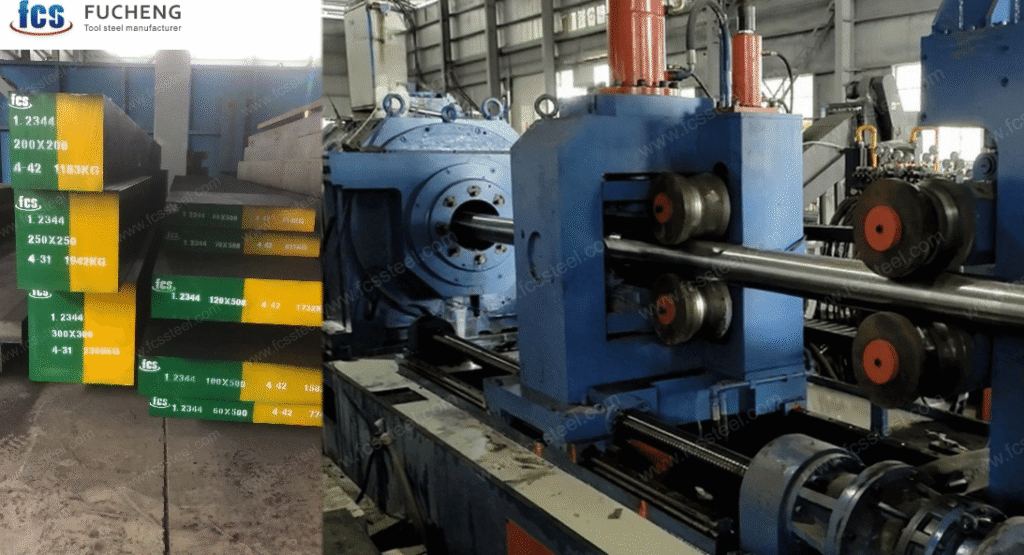

1.2344 Tool Steel (H13 Equivalent)

- Composition: ~0.38% Carbon, 5.0% Chromium, 1.3% Molybdenum, 1.0% Vanadium.

- Category: Hot-work tool steel.

- Key Properties:

- Hardness: 44–52 HRC after heat treatment.

- Excellent hot hardness and thermal fatigue resistance.

- Superior dimensional stability during repeated heating/cooling cycles.

- Common Uses: Die-casting molds, hot extrusion dies, forging dies, high-temperature tooling.

2. Strength and Mechanical Performance

In Querétaro’s automotive and heavy-equipment plants, components must endure both static and dynamic loads.

- 4140:

- Tensile strength ranges between 655–1080 MPa, depending on quenching and tempering.

- Exhibits high fatigue resistance, making it ideal for rotating machinery parts like crankshafts or drive shafts.

- Slightly less wear resistance compared to tool steels.

- 1.2344:

- Tensile strength can exceed 1200 MPa in certain conditions.

- Designed to retain strength even at elevated temperatures (up to 600°C).

- Particularly advantageous in hot forging or die casting, where molds are repeatedly exposed to molten metal at high pressures.

Comparison:

- For cold-load, structural components, 4140 is more cost-effective and provides sufficient strength.

- For hot-work environments, 1.2344 outperforms due to superior thermal stability.

3. Heat Treatment and Quench Response

Heat treatment strongly influences both steels’ performance.

- 4140:

- Quench-hardened and tempered to achieve hardness between 28–32 HRC.

- Oil or water quenching can be used, but distortion risk increases with complex geometries.

- Easily machinable in annealed state, later hardened for use.

- 1.2344:

- Air-hardening steel, reducing the risk of cracking and distortion during quenching.

- Maintains stability even after multiple tempering cycles.

- Typical hardness after treatment: 44–52 HRC.

- Designed to resist softening at high temperatures, making it ideal for mold longevity.

Comparison:

- 4140 is versatile and responds quickly to quenching, but dimensional changes are more likely.

- 1.2344 provides superior stability after repeated heat cycles, essential for precision tooling in die casting.

4. Shape Stability and Thermal Fatigue

For manufacturers in Querétaro producing precision dies and molds for automotive parts, shape stability is crucial.

- 4140:

- Performs well in cold and moderately heated conditions.

- Risk of warping or dimensional drift under prolonged heat exposure.

- Not recommended for continuous high-temperature applications.

- 1.2344:

- High resistance to thermal fatigue cracking, a common failure mode in die-casting.

- Maintains dimensional accuracy across thousands of production cycles.

- Prolonged service life in high-pressure die casting of aluminum or magnesium parts.

Comparison:

- 4140: Best for heavy-duty shafts, gears, and frames.

- 1.2344: Best for molds, dies, and tools exposed to heat-fatigue conditions.

5. Application in Querétaro’s Industries

Automotive Sector

Querétaro is home to major automotive OEMs and suppliers.

- 4140: Suitable for drivetrain components, steering systems, suspension arms.

- 1.2344: Suitable for mold production, particularly in aluminum engine block casting, transmission housings, and high-precision injection molds.

Heavy Machinery and Aerospace

- 4140: Used for hydraulic cylinders, pressure vessels, and machine shafts.

- 1.2344: Favored in aerospace for turbine tooling and molds subjected to high cycle fatigue.

Case Data:

A study from ASM International shows that 1.2344 dies last 2–3 times longer than standard alloy steels in aluminum die casting, reducing downtime and tool replacement costs.

6. Cost and Availability in Mexico

- 4140:

- Widely available in Mexican steel distribution networks.

- Lower price compared to tool steels, making it a cost-efficient choice for large-volume parts.

- 1.2344:

- Higher initial cost due to alloying elements and processing.

- Import reliance for some grades, though suppliers in Monterrey and Querétaro increasingly stock it.

- Longer tool life offsets upfront expenses in high-volume production runs.

7. Selection Guidelines for Querétaro Manufacturers

- Choose 4140 if:

- Components operate at room or moderate temperatures.

- Cost efficiency and toughness are priorities.

- Applications involve shafts, gears, pressure vessels, structural frames.

- Choose 1.2344 if:

- Parts endure high thermal loads and repeated heating/cooling cycles.

- Dimensional stability and tool life are critical.

- Applications involve die casting, forging dies, or high-performance molds.

Conclusion

In Querétaro’s rapidly expanding industrial landscape, the choice between 4140 alloy steel and 1.2344 hot-work tool steel depends largely on application:

- 4140 remains the go-to material for structural and rotating components, valued for its strength, toughness, and cost-effectiveness.

- 1.2344, though more expensive, delivers unmatched performance in thermal fatigue resistance and dimensional stability, making it indispensable in die casting and hot-forging industries.

For Mexico’s automotive and aerospace manufacturers aiming to compete globally, the right balance between 4140 and 1.2344 ensures reliability, efficiency, and long-term cost savings.