1.2360 Tool Steel

At FCS Tool Steel, we offer 1.2360 Tool Steel in multiple supply conditions:

Supply Condition:Annealed,Machined

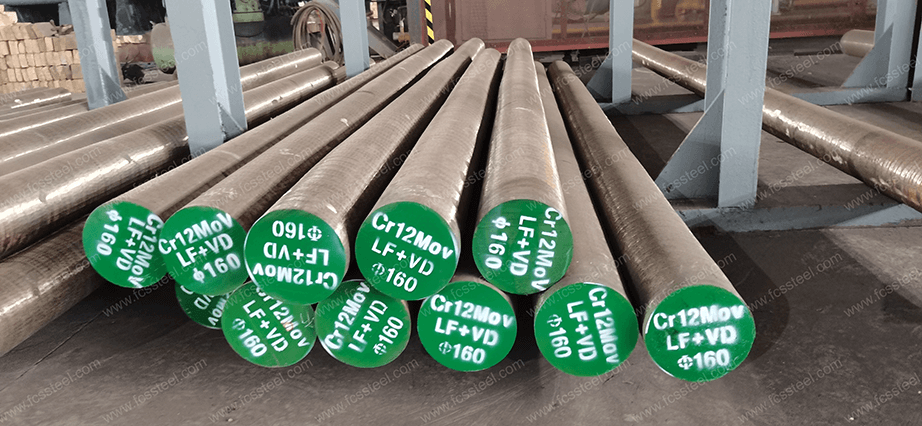

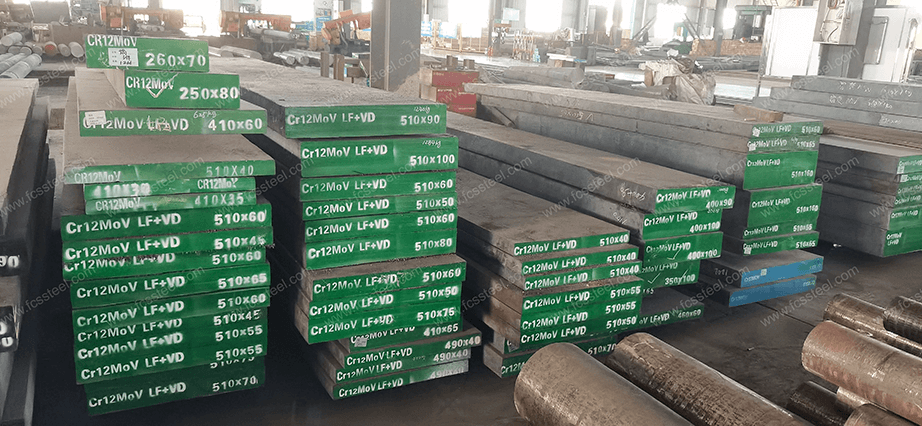

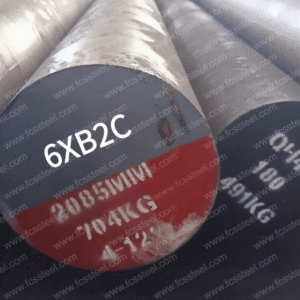

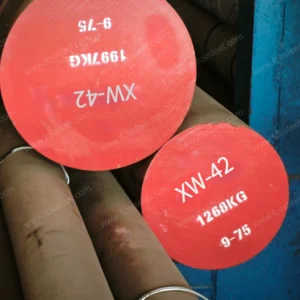

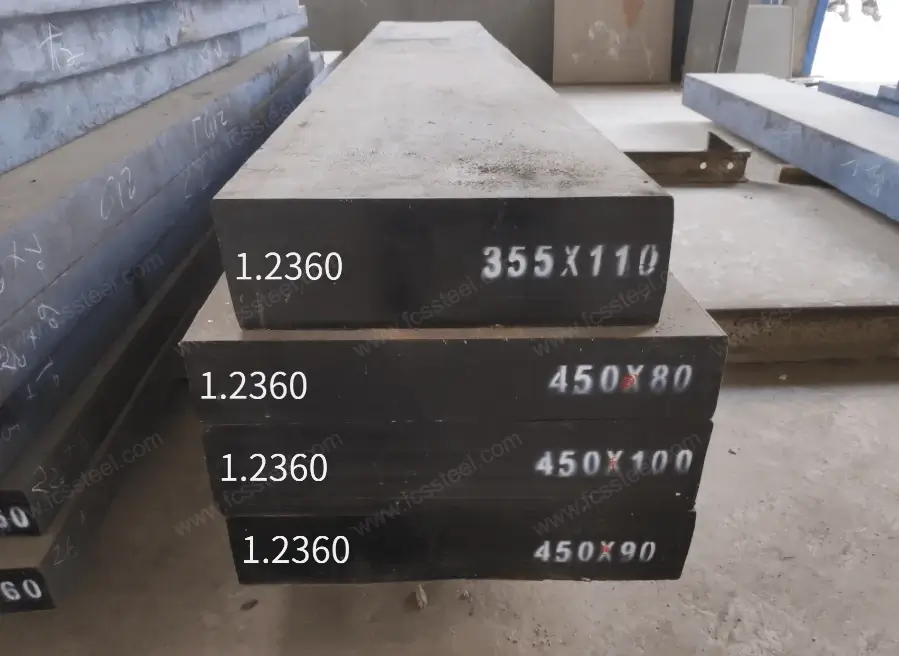

Available Forms:Round bars,Plates / Flat bars,Custom-cut pieces

Processing Services:Sawing,Rough machining,Custom heat treatment.

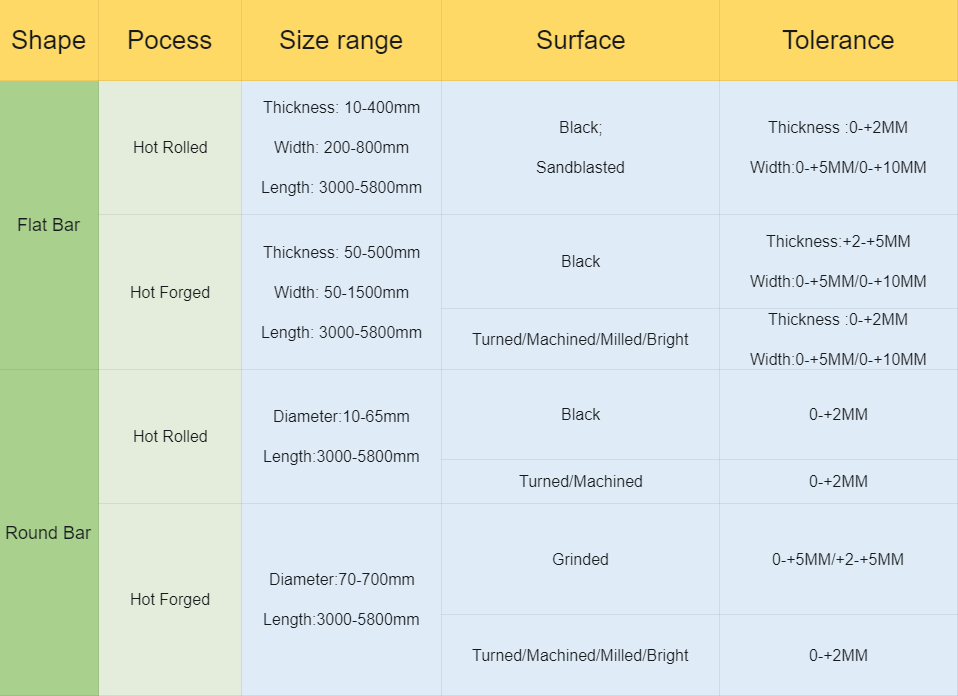

Standard Size Range (Availability varies by stock):

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Forming Methods:Hot Rolled,Hot Forged.

Surface Finish Options:Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

1.2360 Tool Steel:Material Introduction

1.2360 is a kind of composite strengthened cold working tool Steel, belonging to DIN standard X48CrMoV8-1-1, also known as "Chipper Knife Steel". It features high hardenability, excellent toughness and wear resistance, and outstanding dimensional stability after heat treatment. It is widely used in industrial cutting tools and blanking dies.

1.2360 Tool Steel:Product Specification

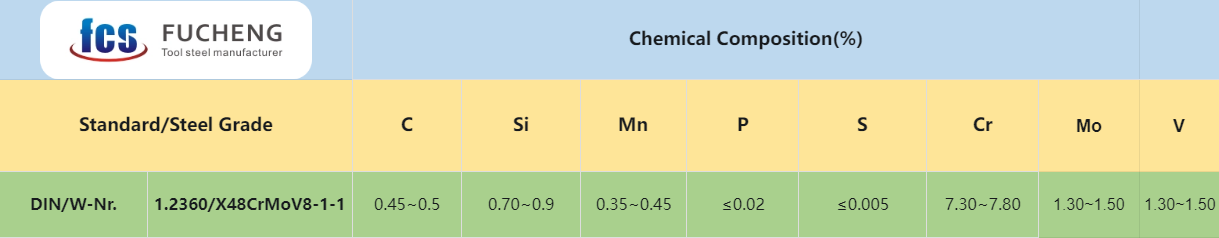

1.2360 Tool Steel:Chemical Composition

1.2360 Tool Steel Equivalent Grades

1.2360 Tool Steel:Heat treatment suggestions

- Annealing: Heat to 820-860 °C → slow furnace cooling, annealing hardness ≤ 240 HB.

- Stress relief (if processed) : approximately 600-650 °C → furnace cooling.

- Quenching: Heat to 950-1070 °C → oil cooling/salt bath/air cooling.

- Tempering: It is recommended to do it within the range of 200-600 ° C. After tempering, the hardness is excellent. The tensile strength is optimal at 400-500 °C.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 135 × 25 cm |

.png)