1.2085 Tool Steel

At FCS Tool Steel, we offer 1.2508 Tool Steel in multiple supply conditions:

Supply Condition:Annealed,Machined

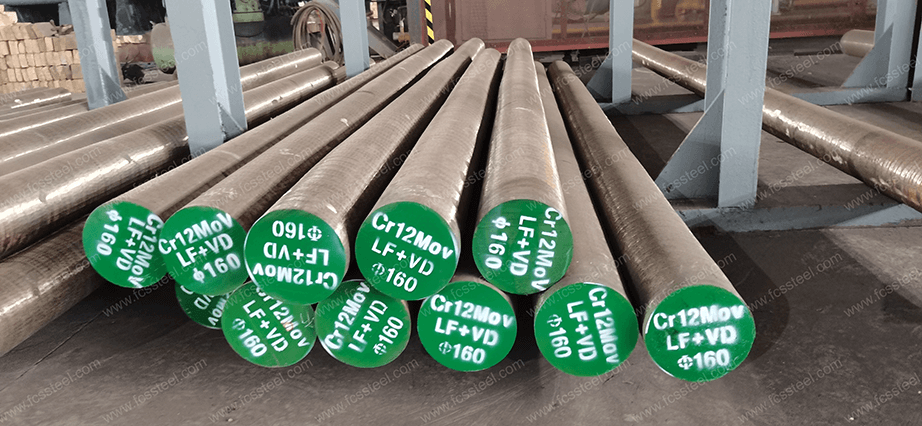

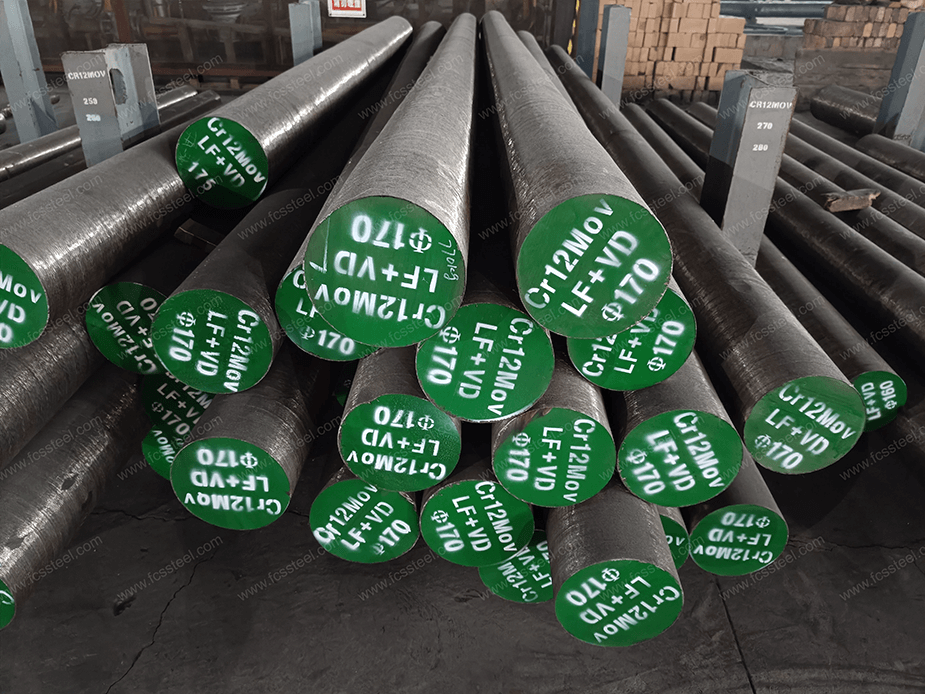

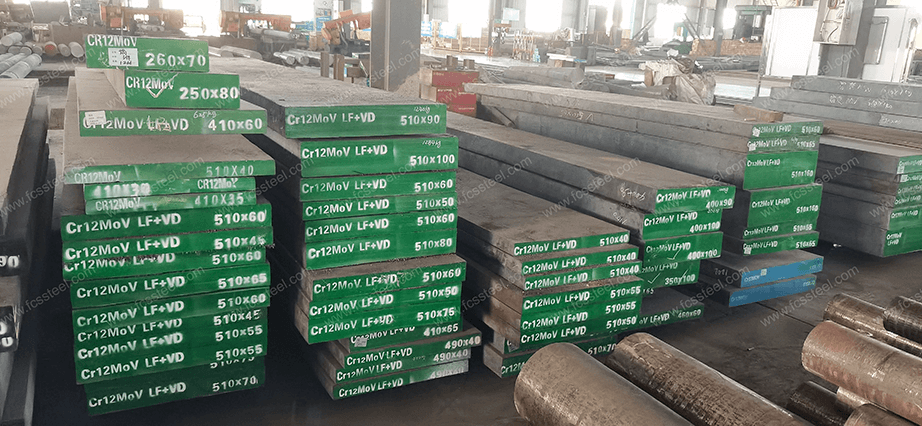

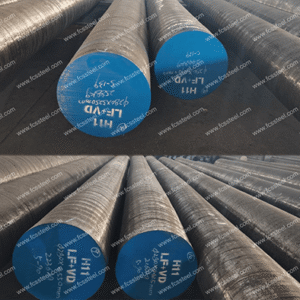

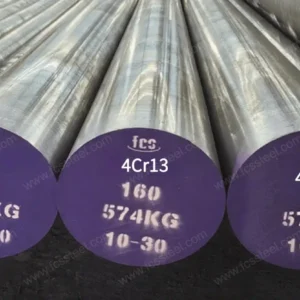

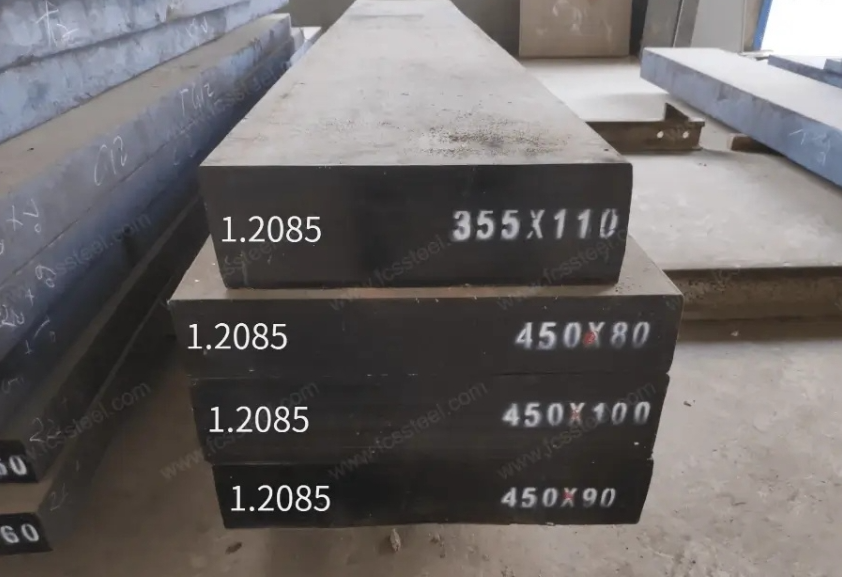

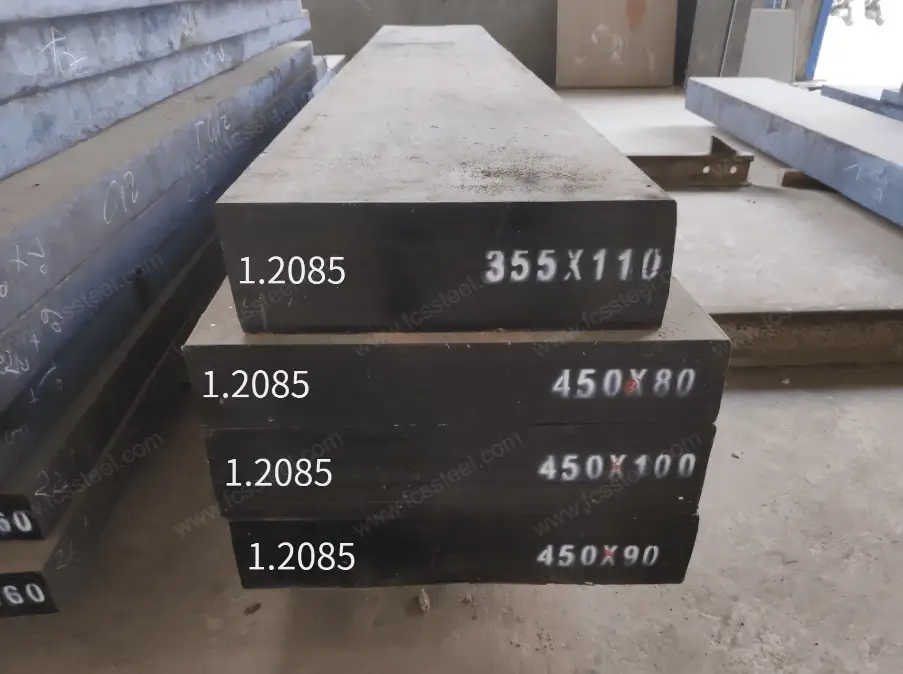

Available Forms:Round bars,Plates / Flat bars,Custom-cut pieces

Processing Services:Sawing,Rough machining,Custom heat treatment.

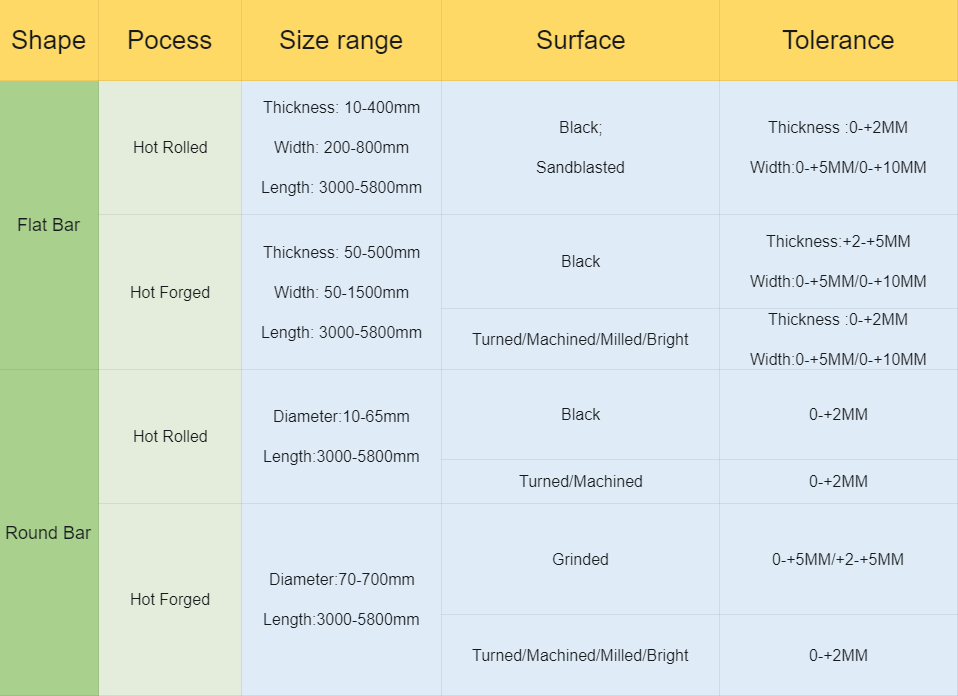

Standard Size Range (Availability varies by stock):

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Forming Methods:Hot Rolled,Hot Forged.

Surface Finish Options:Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

1.2085 Tool Steel:Material Introduction

1.2085 is neither a simple stainless steel tool steel nor a simple plastic tool steel, but a "stainless plastic tool steel" that combines the characteristics of stainless steel (corrosion resistance) with the application of plastic mold steel. 1.2085 (also known as SUS420F/X33CrS16), with high chromium (about 15-17%) as the main alloying element, features excellent corrosion resistance, high hardness and good machinability. Its sulfur content is relatively high, which further enhances the machinability of the machine. It is often used in wet environments or for mold components that require a mirror-like finish.

1.2085 Tool Steel:Product Specification

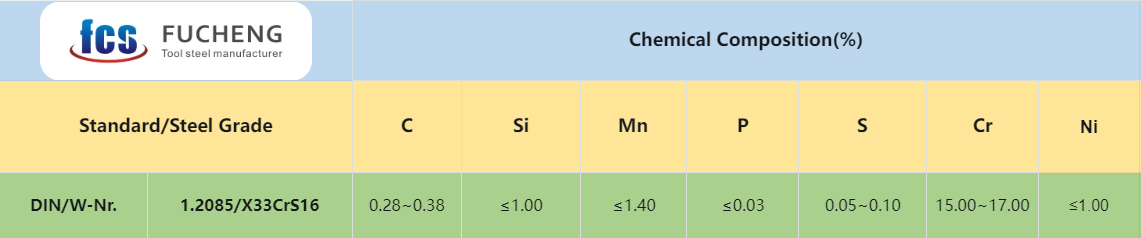

1.2085 Tool Steel:Chemical Composition

1.2085 Tool Steel:Heat treatment guidance

- Annealing: Heat to 850-880 °C and cool slowly in the furnace → obtain a reprocessing state of approximately ≤ 240 HB.

- Quenching: Heat to 1000-1050 °C → Oil or air cooling; It can achieve approximately HRC.

- Tempering: Double tempering at 150-200 °C can suppress quenching stress and stabilize hardness.

1.2085 Tool Steel:Mechanical properties (typical state)

- Yield strength: ≥ 905 MPa

- Tensile strength: 950-1100 MPa

- Elongation: ≥ 10%

- Reduction of area: ≥ 21%

- Annealing hardness: ≤ 230 HBW

- After hardening: It can reach HRC ~48, and is more durable after polishing.

1.2085 Tool Steel:Typical application scope

- Plastic molds (with high requirements for moisture resistance and corrosion resistance)

- Cutting tool and measuring tool components

- Medical devices and pump valve shafts

- Decorative components with high requirements for surface polishing

- Precision tools that need to maintain dimensional stability in corrosive environments

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 135 × 30 cm |

.png)