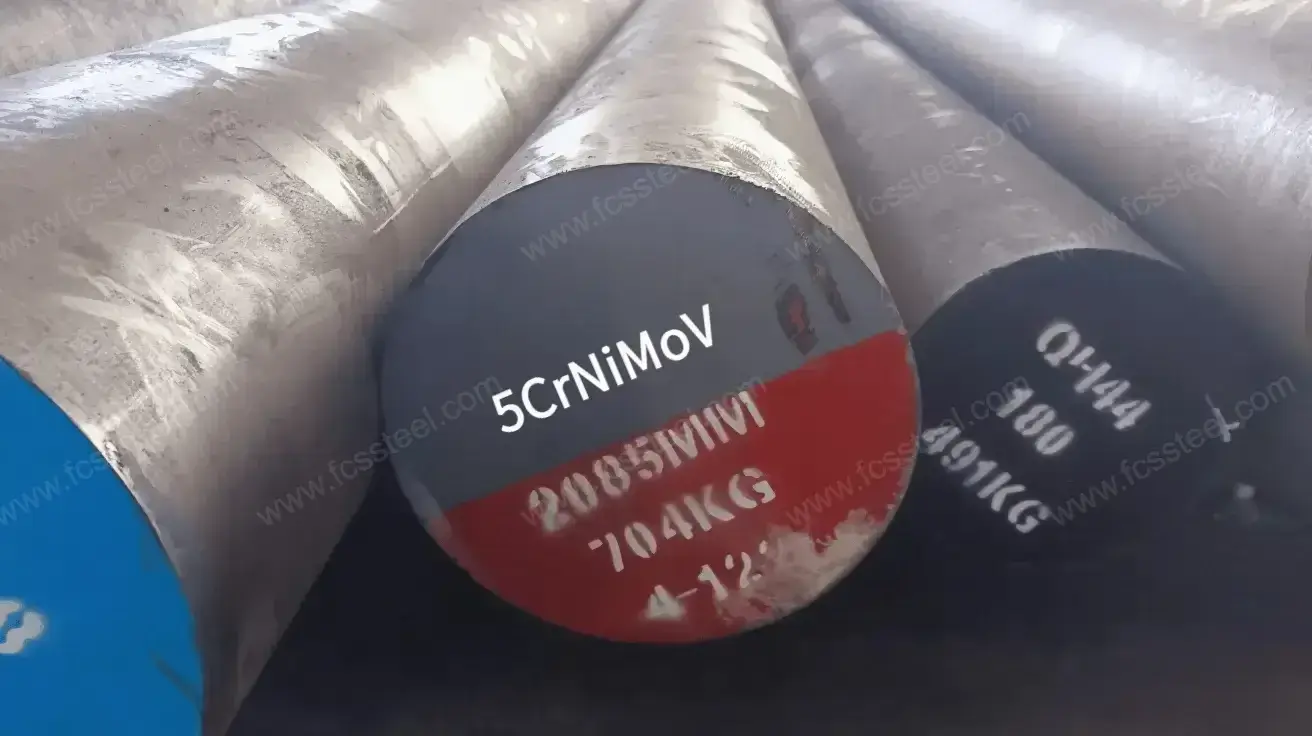

5CrNiMoV Tool Steel

Under heavy forging and impact load conditions, the toughness of the die directly determines its service life. 5CrNiMoV, as a representative of high-toughness hot work die steel in the Chinese national standard (GB/T 1299), has solved the industry pain points of easy cracking and short service life of large forging dies through high nickel content and vanadium-molybdenum composite strengthening. Its room-temperature impact energy is ≥40J, and it maintains a stable structure even at working temperatures of 400-500℃, making it the preferred material for automotive crankshafts and forging dies for construction machinery.

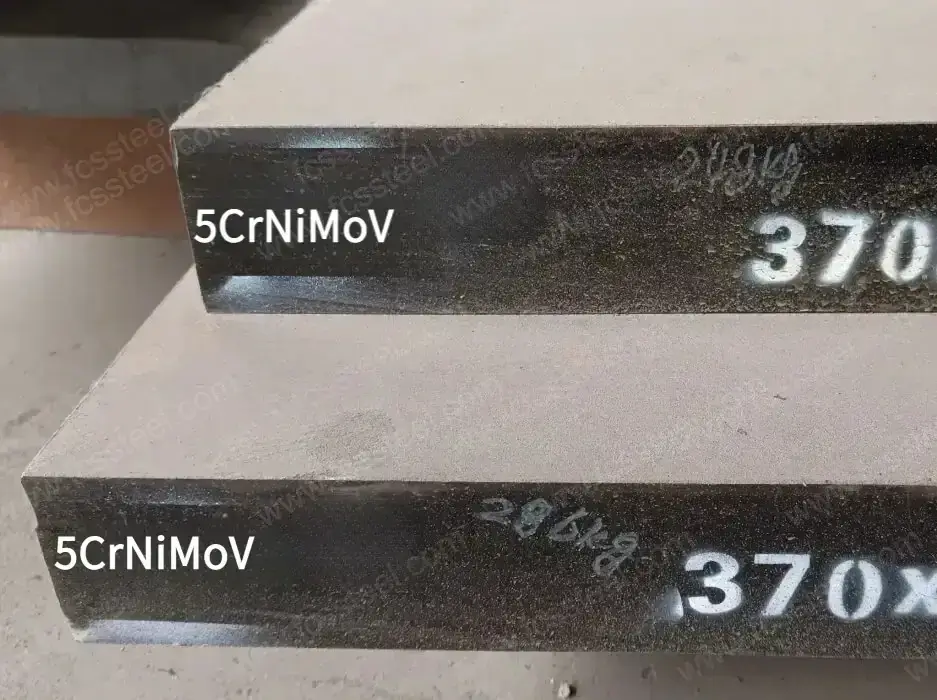

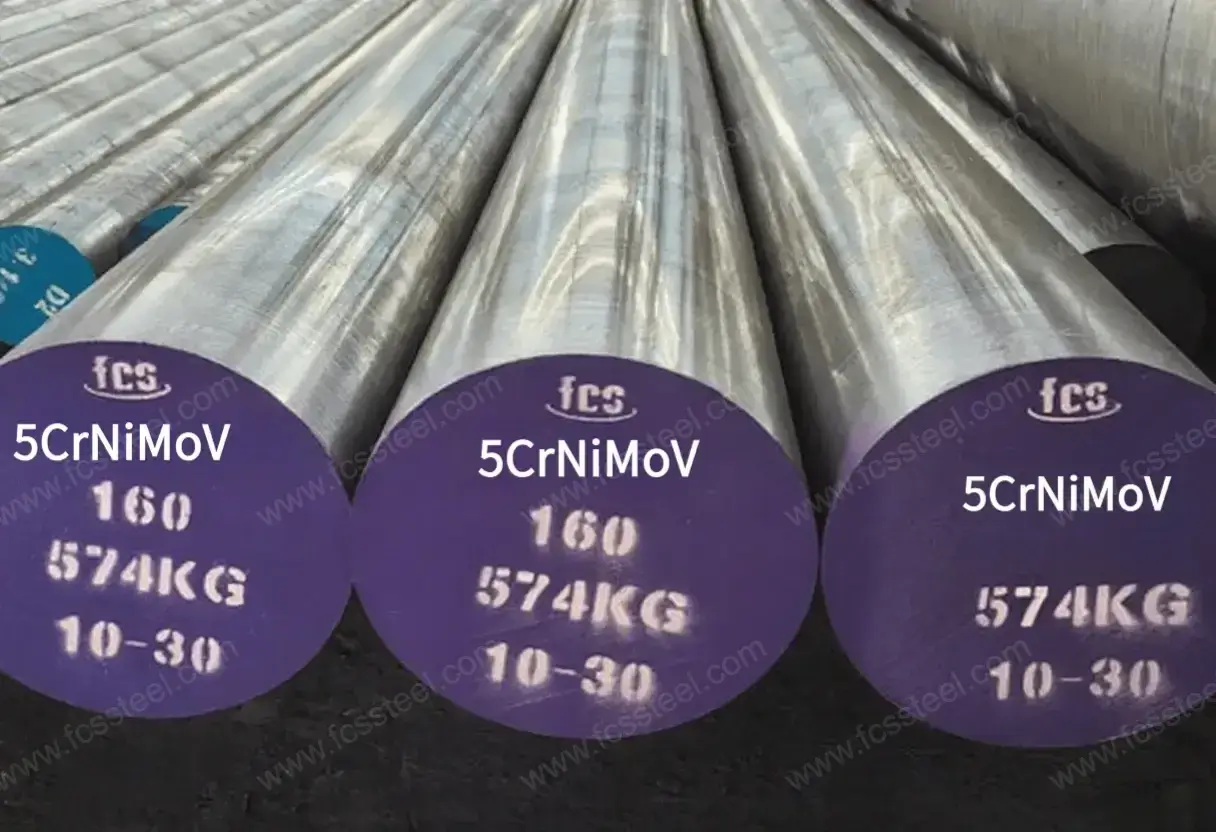

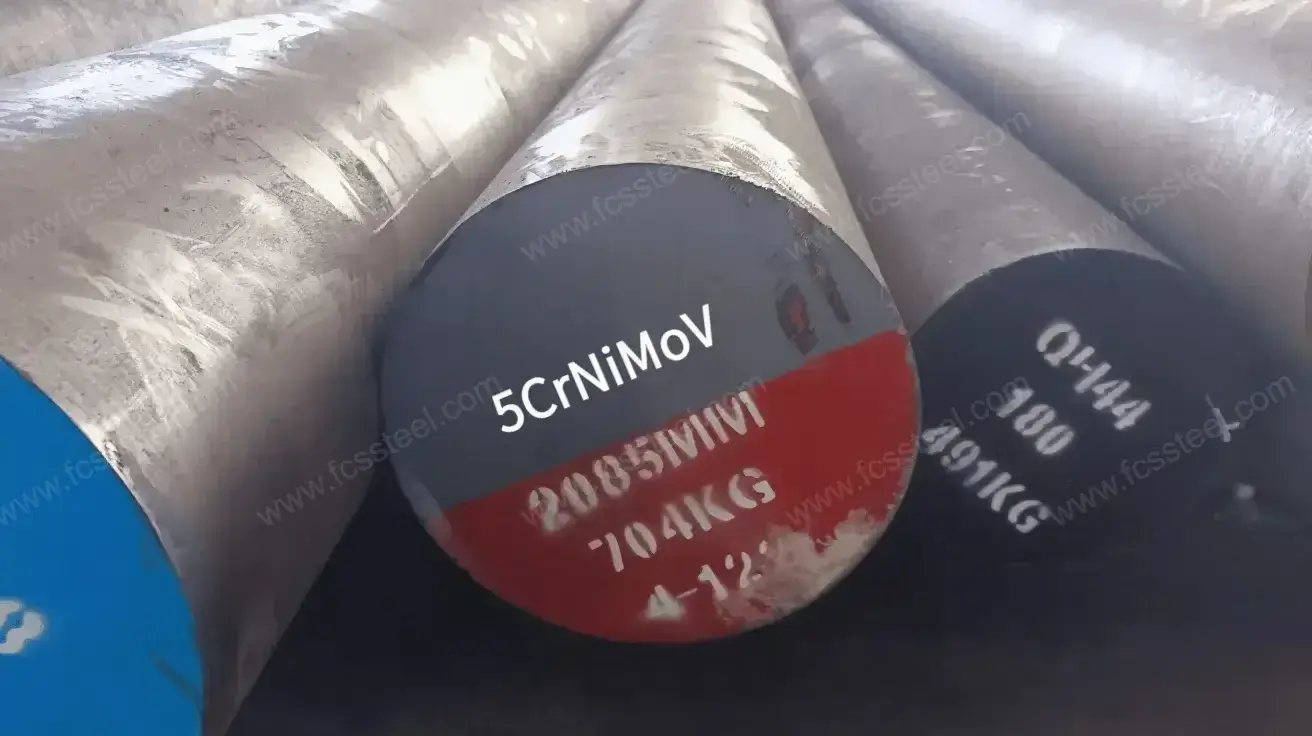

5CrNiMoV Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

5CrNiMoV Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

5CrNiMoV Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 5CrNiMoV Tool Steel?

5CrNiMoV is a highly wear-resistant hot forging die steel that is highly praised under the Chinese national standard system. Its composition design is extremely ingenious, achieving an outstanding balance in toughness, strength and wear resistance. During the production process, the advanced technology of electric furnace (EF) + refining (LT) + vacuum (VD) is adopted, which greatly enhances the purity of the die steel and lays a solid foundation for its outstanding performance.

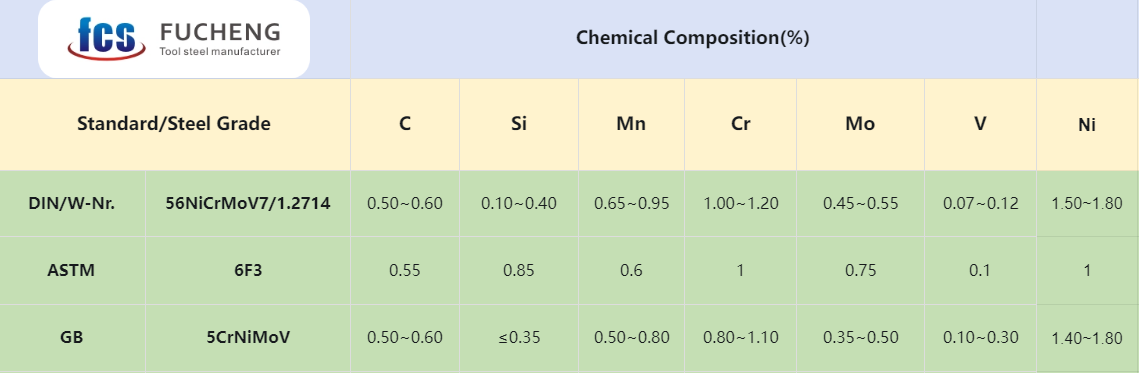

International Equivalent Grades of 5CrNiMoV Tool Steel

Chemical Composition of 5CrNiMoV Tool Steel

5CrNiMoV Steel Product Specifications

5CrNiMoV Steel:Heat treatment process and performance parameters

- Annealing: Annealing at 760-780 °C results in a hardness of approximately 197-241 HB.

- Quenching: Quench at 890-910 °C to oil cooling or gas cooling, with hardness reaching approximately 61.5 HRC.

- Tempering: The tempering temperature range is 420-550 ° C. Double tempering can adjust the final hardness to 38-47 HRC.

After heat treatment, this steel features high hardness, stable dimensions and good toughness, making it suitable for high-stress environments.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 180 × 40 × 30 cm |