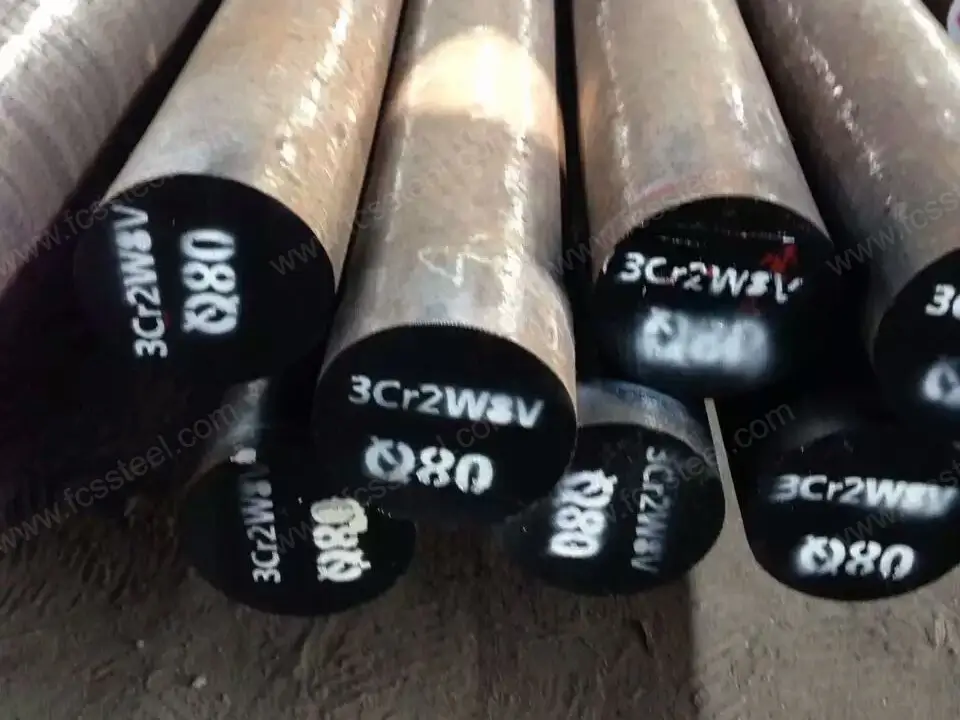

3Cr2W8V Tool Steel

3Cr2W8V alloy tool steel is a special steel grade formed by adding alloying elements to carbon tool steel, specifically designed for high-temperature and high-pressure working environments. As a representative of hot work die steel, it has achieved a breakthrough improvement in high-temperature performance through a unique composition combination.

3Cr2W8V Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

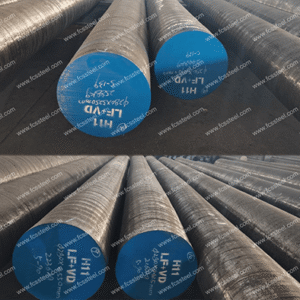

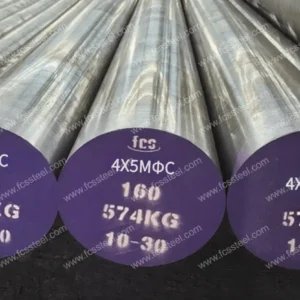

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

3Cr2W8V Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

3Cr2W8V Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 3Cr2W8V Tool Steel?

Under extreme working conditions of high temperature and high pressure, ordinary mold steel often finds it difficult to withstand continuous cold and hot cycles and mechanical stress. As a representative steel grade of hot work die steel in the Chinese national standard (GB/T 1299), 3Cr2W8V has solved this industry pain point through reasonable chemical composition balance and heat treatment process.

Its high thermal fatigue resistance and excellent hardenability make it an ideal choice for high-temperature forming processes such as die-casting and hot extrusion, especially suitable for the processing of non-ferrous metals like copper alloys and aluminum alloys.

International Equivalent Grades of 3Cr2W8V Tool Steel

Chemical Composition of 3Cr2W8V Tool Steel

3Cr2W8V Steel Product Specifications

3Cr2W8V Tool Steel:Performance features and application directions

- It has remarkable resistance to high-temperature fatigue and is suitable for continuous high-temperature operations.

- Hard and wear-resistant, it is suitable for scenarios such as thermal shearing and high-pressure die-casting.

- It has excellent toughness and is suitable for complex mold structures and heavy-load impacts.

Common applications include: die-casting molds, hot extrusion tools, precision forging dies, hot punches and high-temperature trimming tools.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |