4Cr5MoSiV1 Tool Steel

4Cr5MoSiV1 tool steel, by rationally proportioning Cr, Mo, Si and V elements, takes into account thermal hardness, wear resistance and thermal fatigue resistance, and is suitable for various mold application scenarios subject to thermal shock and high-temperature wear.

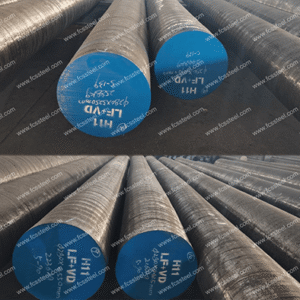

4Cr5MoSiV1 Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

4Cr5MoSiV1 Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

4Cr5MoSiV1 Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 4Cr5MoSiV1 Tool Steel?

4Cr5MoSiV1 is a representative hot work die steel in the Chinese GB/T 1299 standard, which is the domestic counterpart to the international H13 (DIN 1.2344, SKD61).

International Equivalent Grades of 4Cr5MoSiV1 Tool Steel

Chemical Composition of 4Cr5MoSiV1 Tool Steel

4Cr5MoSiV1 Steel Product Specifications

4Cr5MoSiV1 Steel Heat treatment suggestions

- Annealing: Hold at 860-890 °C for several hours and then cool slowly, target hardness ≤229 HBW.

- Quenching: Heat at 1020-1080 °C and then air or oil cool. The effective hardness can reach 56-58 HRC (slightly lower for large cross-sections).

- Tempering: Generally, double tempering at 560-580 °C is selected, and the final hardness is stabilized at 47-49 HRC. Tempering at 200 °C can be carried out after processing to relieve internal stress.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |