Cr12Mo1V1 Tool Steel

Cr12Mo1V1 tool steel, whose structure belongs to ledeburitic cold-work steel, combines excellent wear resistance, good hardenability and stronger red hardness, making it an ideal material for manufacturing high-precision molds and industrial cutting tools.

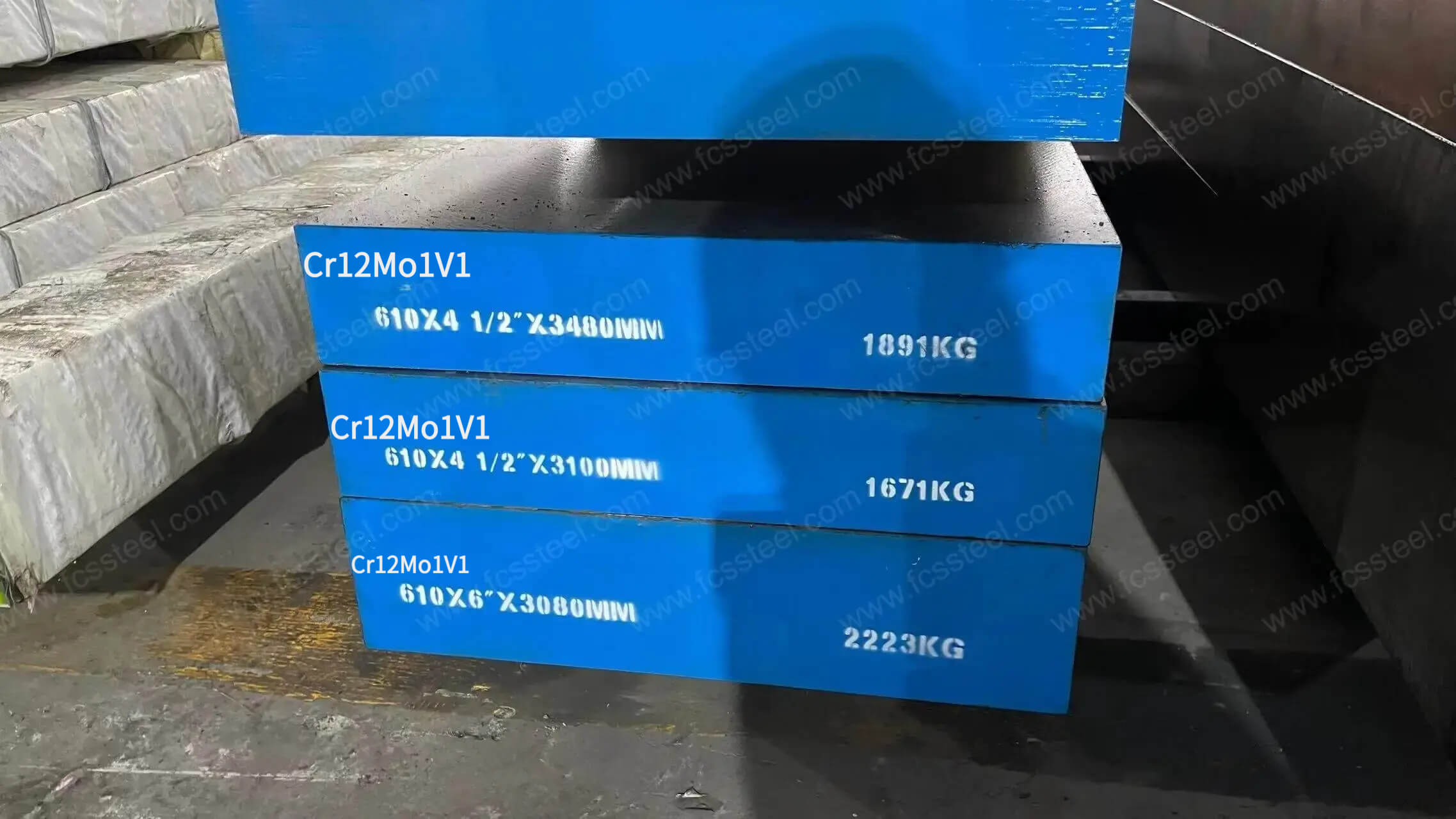

C12MoV:Product Form and Inventory Specifications

- Cr12Mo1V1 Supply status: Annealed state, machined state.

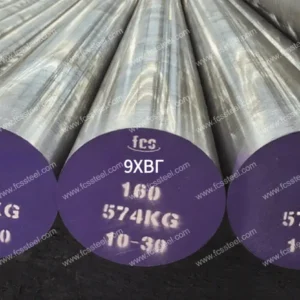

- Cr12Mo1V1 Delivery form: Round steel, plates/flat bar,custom cutting.

- Cr12Mo1V1 Processing services: sawing, rough machining, custom heat treatment.

- Cr12Mo1V1 Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc.

Cr12Mo1V1 Tool Steel Forming Process Options

Cr12Mo1V1 Hot Rolled,Cr12Mo1V1 Hot Forged

Cr12Mo1V1 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is Cr12Mo1V1 Tool Steel?

Cr12Mo1V1 is a high-carbon and high-chromium cold work die steel under the Chinese GB standard system. It is based on Cr12MoV with a higher vanadium (V) content to replace the international D2 / SKD11 (DIN 1.2379) steel grade.

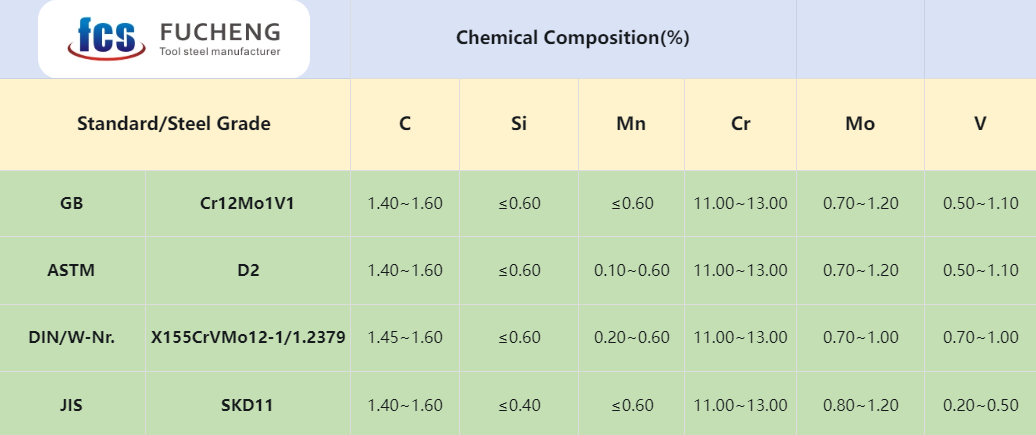

International Equivalent Grades of Cr12Mo1V1 Tool Steel

Chemical Composition of Cr12Mo1V1 Tool Steel

Cr12Mo1V1 Steel Product Specifications

Cr12Mo1V1 Steel Heat treatment standards and performance indicators

- The process condition for the annealed state is slow cooling at 800–850 °C, with a hardness range of ≤255 HB. Its performance characteristics are easy mechanical processing and shape handling.

- The process condition for the quenched + tempered state is quenching at 1020–1050 °C followed by low-temperature tempering, with a hardness range of 60–62 HRC. Its performance characteristics include extremely high wear resistance, improved toughness, and suitability for high-pressure stamping die structures.

- It is recommended to temper two to three times to avoid softening and cracking. At the same time, avoid prolonged tempering above 700 °C.

Cr12Mo1V1 Steel Typical application fields

Cr12Mo1V1 is often used in working conditions with high precision, high strength and high wear resistance requirements, and is compatible with the following molds and tools:

-

- Blanking dies, drawing dies, precision shearing dies.

- Drawing dies, cold extrusion dies and thread rolling/threading wheels.

- Powder metallurgy die and punching structural component die.

- Precision gauges, industrial edge trimming tools, blanking cutting tools, etc.

- It is particularly suitable for the fields of automotive hardware, electrical parts, bearings and electronic components.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |