Cr12W Tool Steel

Cr12W is a preferred material among domestic cold work die steels that combines high wear resistance and thermal stability, and its performance is close to AISI D6 tool steel.

C12W:Product Form and Inventory Specifications

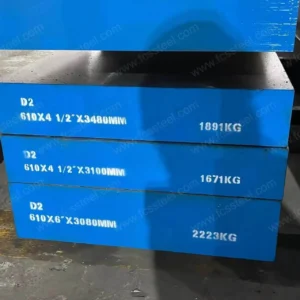

- Cr12W Supply status: Annealed state, machined state.

- Cr12W Delivery form: Round steel, plates/flat bar,custom cutting.

- Cr12W Processing services: sawing, rough machining, custom heat treatment.

- Cr12W Optional sizes: Diameter Φ10 ~ Φ65/Φ 70 ~ Φ400/500/600/700 mm,thickness 8-45/50-500mm,width 50-1000mm/50-1500mm, Forged disc ≤ 1200mm,

etc

Cr12W Tool Steel Forming Process Options

Cr12W Hot Rolled,Cr12W Hot Forged

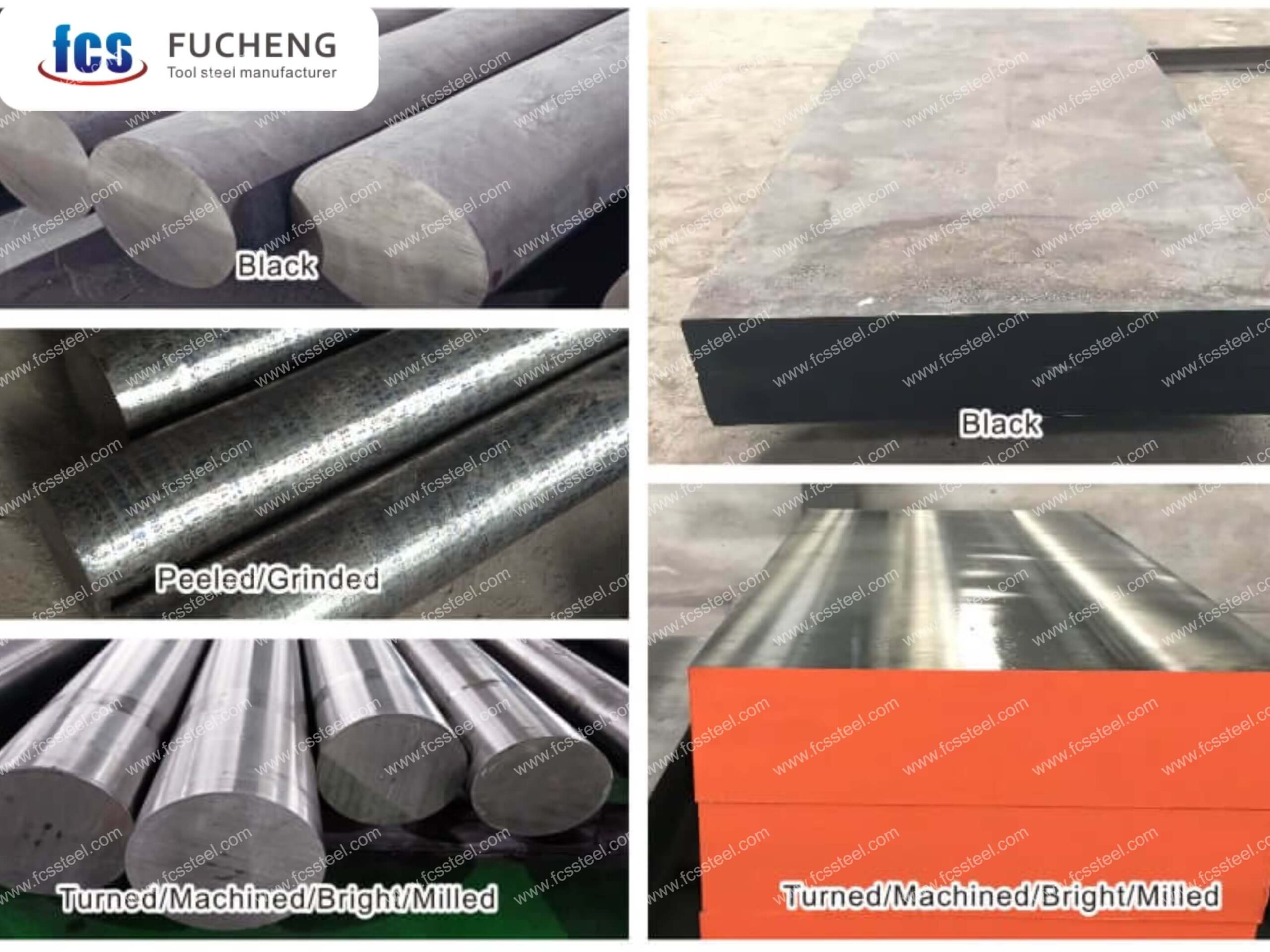

Cr12W Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

What is Cr12W Tool Steel?

Cr12W is a high-carbon and high-chromium cold working tool steel defined in the Chinese national standard GB/T 1299-2000. Its characteristic is that an appropriate amount of tungsten (W) element is added to the Cr12 composition system to enhance its wear resistance and red hardness. It belongs to the Ledeburitic structure steel type and is suitable for manufacturing cold working dies with high wear resistance requirements and harsh working conditions.

Compared with common Cr12 or Cr12MoV, Cr12W demonstrates superior thermal stability and service life under continuous impact or medium-temperature operation, making it particularly suitable for high-speed blanking dies, punching dies, and tools that require sharp cutting edges for long periods of time.

International Equivalent Grades of Cr12W Tool Steel

Chemical Composition of Cr12 Tool Steel

Cr12W Steel Product Specifications

The advantages of Cr12W Steel

- It has higher wear resistance than Cr12 and Cr12MoV and is suitable for high-friction working conditions.

- It has strong thermal stability and excellent anti-softening performance at the cutting edge.

- After quenching, the hardness is high, reaching up to 64HRC.

- Long service life, suitable for mass production of molds.

Cr12W Steel Quality standards and inspection

- Execution standard: GB/T 1299-2000 "Alloy Tool Steel".

- Flaw detection standard: Qualified at grade D/d.

- Inspection methods: Component spectral analysis, hardness testing, ultrasonic flaw detection, metallographic microscopy.

-1-300x300.png)