SKD6 Tool Steel

SKD6 tool steel is a hot-work die steel specified in Japan’s JIS G4404 standard, corresponding to the American AISI H11. It is a Cr-Mo tool steel with medium vanadium content. Its main advantages lie in good toughness and resistance to heat cracking, making it suitable for die applications under medium heat load, such as hot shearing knives, hot punches, and die casting cores.

Compared with high-vanadium hot-work steels, SKD6 is slightly inferior in high-temperature strength and red hardness, but it offers better machinability and dimensional stability during heat treatment. It is especially suitable for die components requiring multiple machining operations or high dimensional accuracy.

International equivalent grades of SKD6 include: China’s GB 4Cr5MoSiV, the United States’ AISI H11, Germany’s DIN X38CrMoV5-1 (1.2343), Russia’s GOST 4Х5МФС. With its balanced performance and good cost-effectiveness, SKD6 is widely used in aerospace part forming, aluminum alloy extrusion dies, and hot shearing equipment.

SKD6 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SKD6 Mould Steel:

SKD6 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- SKD6 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

SKD6 Tool Steel Chemical Composition

SKD6 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

SKD6 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

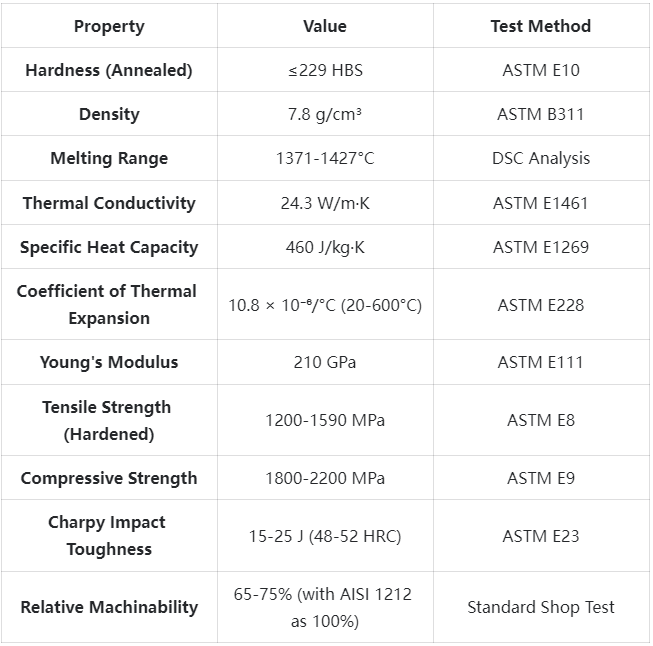

SKD6 Tool Steel Technical Specifications

SKD6 Tool Steel Product Applications

Main application scenarios

Forging dies and tools

Hot forging operations benefit from SKD6's excellent resistance to mechanical and thermal fatigue. The steel's toughness prevents premature cracking while maintaining wear resistance at forging temperatures. When an aerospace component supplier used our SKD6 forging dies, tool life was increased by 35% and the dimensional consistency of the forged parts improved, leading directly to improved manufacturing efficiencies and lower cost per part.

HOT SHEAR BLADES

SKD6 combines high hardness, wear resistance and toughness, making it ideal for hot shear blades used in steel mills and metal fabricators. These blades maintain cutting edge integrity at high temperatures for clean cuts and extended maintenance intervals. One steel fabricator reduced blade replacement frequency by 45% with our SKD6 hot shear blades.

Plastic moulds for high temperature resins

For injection moulding of high temperature engineering plastics (PPS, PEI, PEEK), SKD6 offers excellent wear resistance and polishability. Its thermal properties ensure efficient heat transfer and stable cooling, producing high-quality moulded parts with reduced cycle times. One manufacturer of electronic components reported improved surface finish quality and 25% faster cycle times after upgrading to our SKD6 moulds.

Industry-specific applications

- Automotive industry: transmission component dies, engine block dies, suspension component forging dies.

- Aerospace: turbine blade forging tools, structural component extrusion dies, high-strength fastener tools.

- Electronics industry: heat sink extrusion dies, connector dies, semiconductor packaging tools.

- Construction industry: aluminium window frame extrusion dies, structural steel forging tools.

- Consumer Goods: durable component dies, appliance component tooling.

- Military / Defence: precision component tooling for critical applications requiring Military / Defence: precision component tooling for critical applications requiring reliability.

- Medical Equipment: surgical instrument tooling, implant component tooling requiring high accuracy.

SKD6 Tool Steel Competitive Advantage Comparison

SKD6 Tool Steel Customer Success Stories

SKD6 Tool Steel Pricing Structure Information

SKD6 Tool Steel Frequently Asked Questions

Q: How does SKD6 compare to standard H13 tool steel?

A: SKD6 is a Japanese grade (JIS) that is roughly equivalent to AISI H13, but our SKD6 has tighter chemical composition control, optimised machining and tighter quality control within the H13 specification, resulting in superior performance characteristics, particularly in terms of thermal fatigue resistance and toughness.Q: Can SKD6 be welded and repaired?

A: Yes, SKD6 can be successfully welded using the proper procedures; we recommend preheating to 315-370°C, using compatible filler materials, maintaining interlayer temperatures, and post-weld heat treatment. Our technical support team can provide detailed welding procedures for your specific application.Q: How does section size affect the performance of SKD6?

A: SKD6 maintains good hardenability up to a cross-section size of approximately 150mm. Larger cross sections may result in progressively lower core hardness. For critical applications in tools and moulds with large cross sections, we recommend SKD6-SD (Special Deep Hardening variant) or consider a high end electroslag remelting / vacuum arc remelting grade to enhance full cross section hardness.Q: How should SKD6 be stored prior to use?

A: It should be stored in a dry, temperature-controlled environment to prevent corrosion. Light oil should be applied for long term storage. Large sections should be properly supported to prevent warping. If corrosion occurs, it should be thoroughly removed prior to heat treatment.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |