H10 Tool Steel | 1.2365 | X32CrMoV3-3

In high temperature working environments, common mould steels face severe challenges of thermal fatigue cracking, premature softening and insufficient wear resistance, resulting in reduced productivity and high cost of frequent mould replacement.

As a professional mould steel supplier, FCS TOOL STEEL’s H10/1.2365/X32CrMoV3-3 hot-working mould steel offers excellent hot-hardness and hot-fatigue resistance through optimised chemical composition and special heat treatment processes. The innovation of this premium chromium-molybdenum-vanadium alloyed steel lies in its well-balanced elemental ratio, which ensures excellent hardness and wear resistance at operating temperatures of up to 650°C.

Customers using FCS Factory’s H10 tool steel have seen significant improvements in mould life of 30-50%, reducing downtime and replacement costs. In die casting environments with continuous high-temperature operations, the material exhibits excellent resistance to thermal shock and adhesion, bringing significant economic benefits and performance gains to your production process.

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Product Introduction

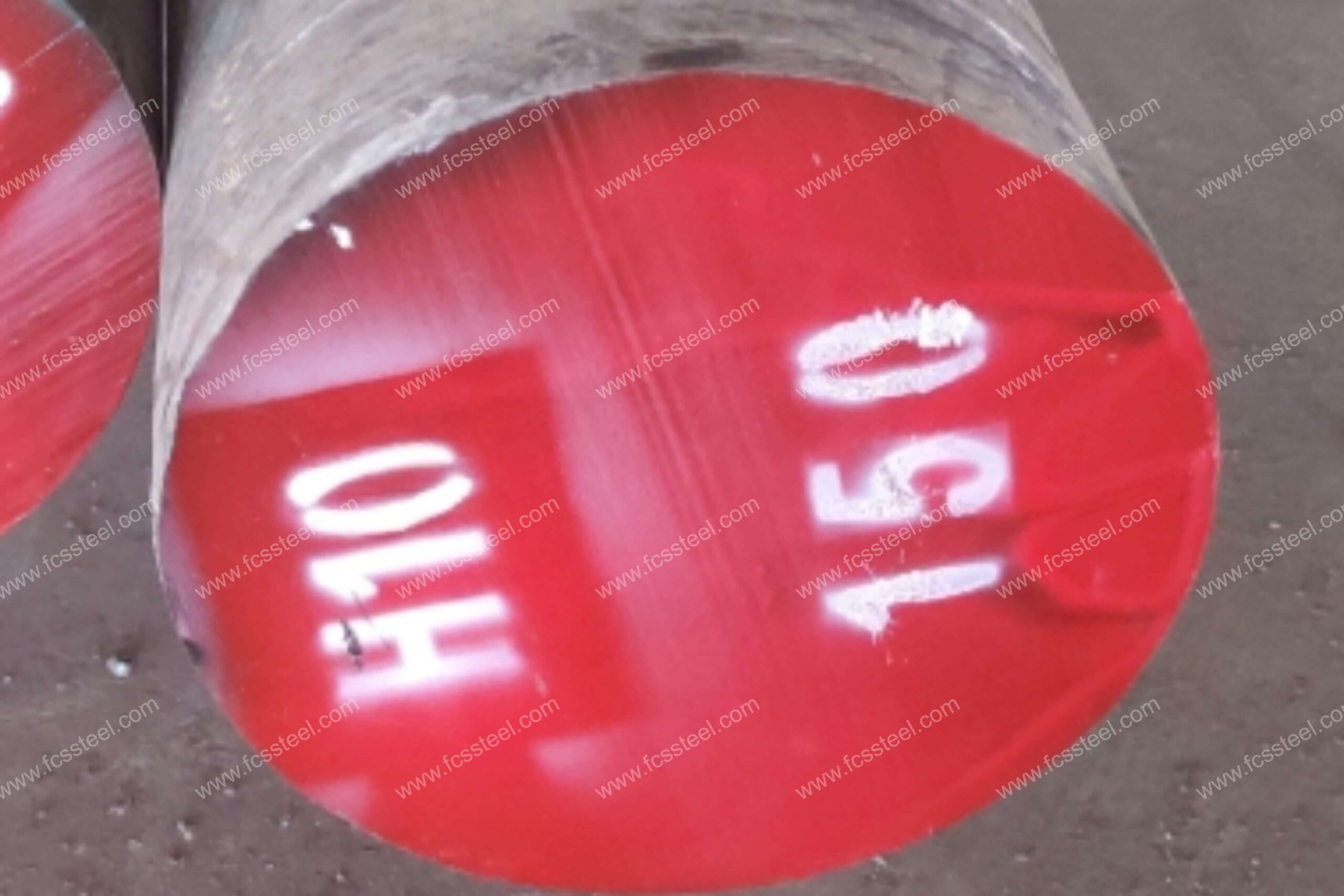

H10 Tool Steel

H10 tool steel is a chromium-molybdenum hot work tool steel characterised by low thermal conductivity and insensitivity to temperature changes. Its chemical composition contains 0.35-0.45% carbon, 3.00-3.75% chromium, 2.00-3.00% molybdenum, and small amounts of silicon and manganese, giving it medium corrosion resistance (grade 3/6) and excellent resistance to thermal cracking. Physical properties include a density of 7.78 g/cm³ and a thermal conductivity of 32.8 W/(m-K) in the annealed state; the hardness after heat treatment is up to 50-52 HRC, with performance optimisation to be achieved by quenching in oil or air-cooling at 1000-1030°C and tempering at 450-570°C The steel should be oil quenched or air cooled at 1000-1030°C and tempered at 450-570°C to optimise properties.

1.2365 Tool Steel

1.2365 tool steel (corresponding to the German W-Nr/DIN standard) is a high-alloyed hot work tool steel with a composition of 0.28-0.35% carbon, 2.70-3.20% chromium, 2.60-3.00% molybdenum, and 0.40-0.70% vanadium. 0.70%, emphasising high temperature stability and wear resistance. It has a density of 7.85 g/cm³ and a thermal conductivity of 33 W/(m-K) at 400-600°C; heat treatment is by quenching at 1020-1050°C (oil/air-cooling) and tempering at 500-650°C, and hardness can be regulated to 40 -55 HRC, while the yield strength ≥ 730 MPa, elongation ≥ 14%.

X32CrMoV3-3 tool steel

X32CrMoV3-3 tool steel (DIN, Germany) has a composition highly consistent with 1.2365: 0.28-0.35% carbon, 2.70-3.20% chromium, 2.60-3.00% molybdenum, 0.40-0.50% vanadium. -0.70%, with emphasis on hardenability and high temperature strength. Physical parameters include a density of 7.85 g/cm³ and a coefficient of thermal expansion (20-100°C) of 11.8 x 10-⁶ K-¹; hardened at 1020-1060°C and tempered at 520-700°C, it reaches a hardness of 50-700°C. After hardening and tempering, it reaches a hardness of 50-700°C. After quenching at 1020-1060°C and tempering at 520-700°C, it has a hardness of 50-52 HRC, a tensile strength of ≥980 MPa and excellent resistance to thermal fatigue.

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Types and Options

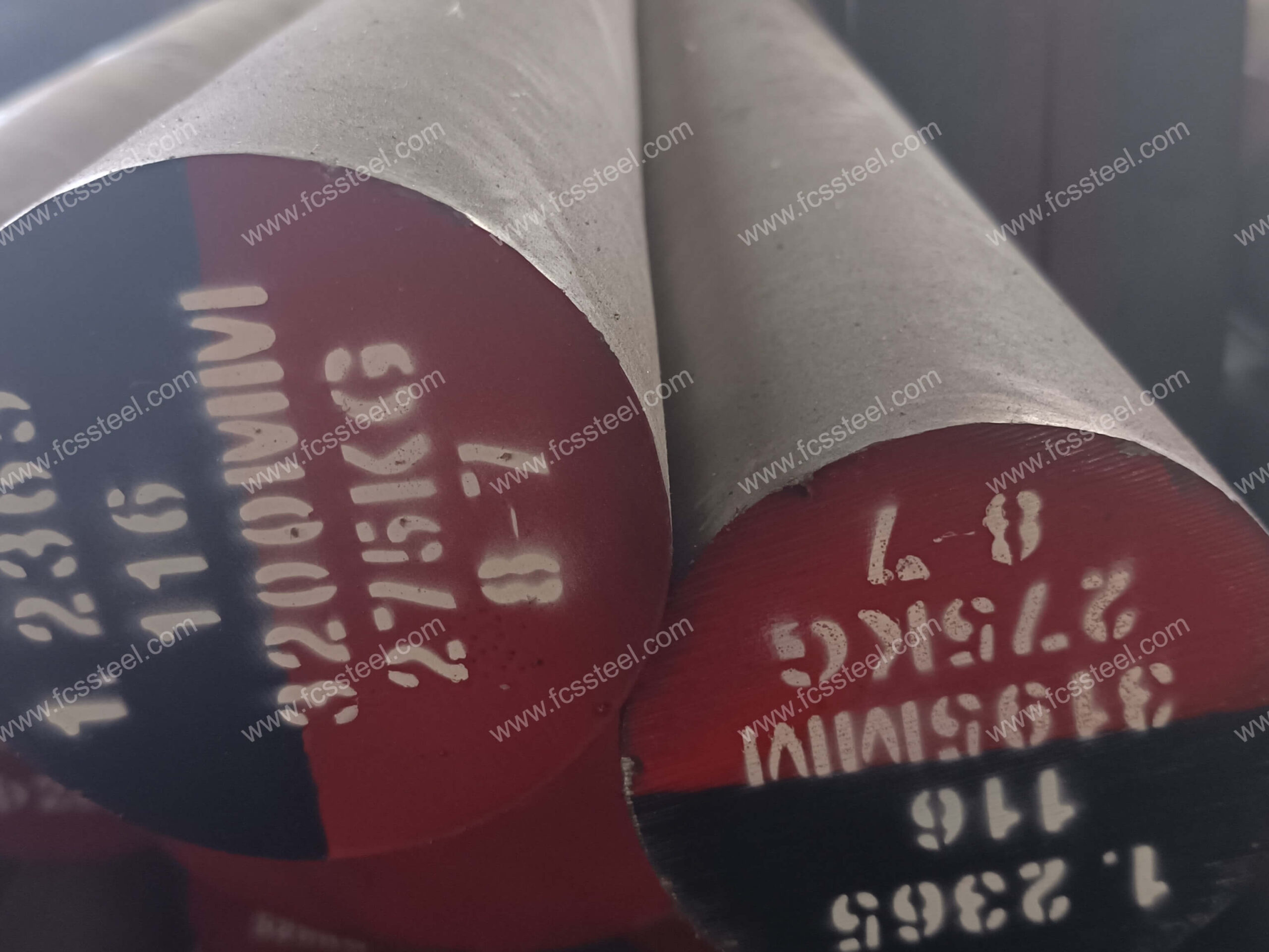

The table below shows the size range, surface condition and tolerance details for H10/1.2365/X32CrMoV3-3 Tool Steel:

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- H10/1.2365/X32CrMoV3-3 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

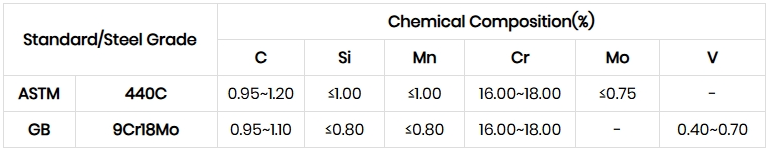

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Chemical Composition

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

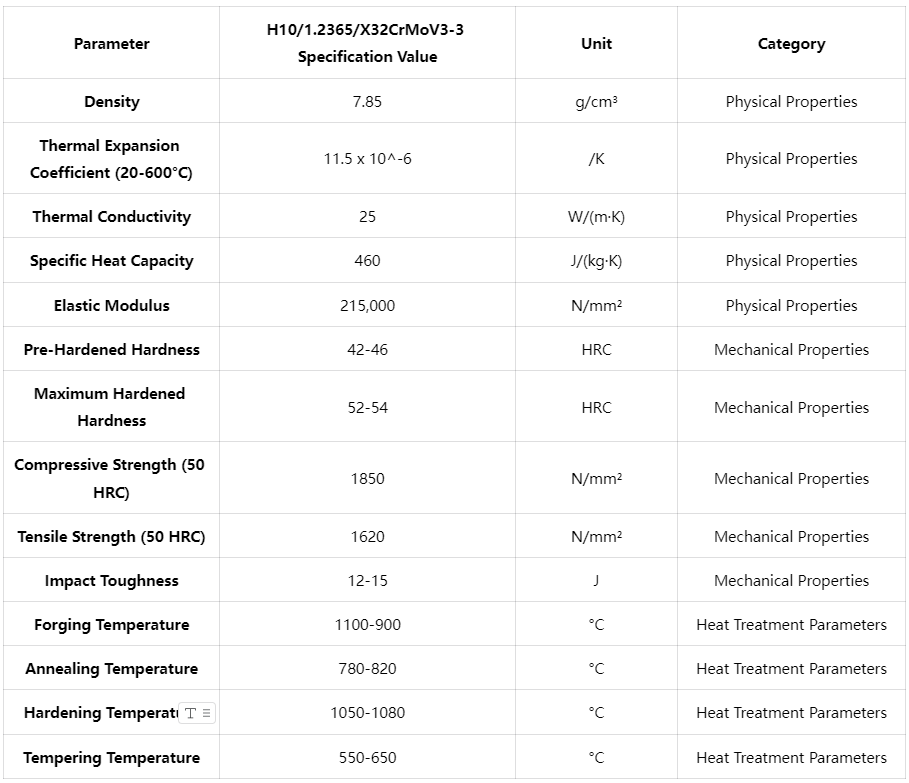

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Technical Specifications

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Product Applications

Key Usage Scenarios

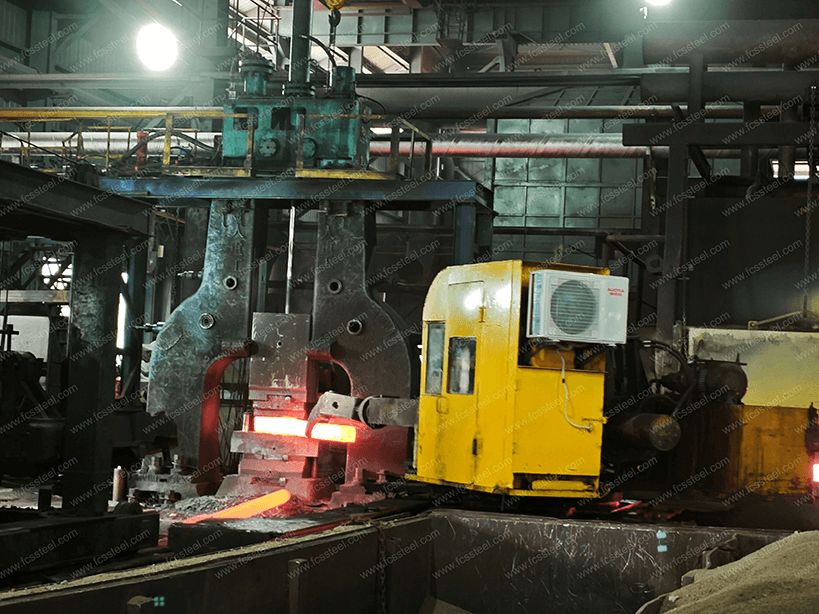

Hot Forging Die Applications

In the hot forging process, H10/1.2365 tool steel demonstrates excellent high temperature strength and wear resistance. An industrial forging plant used our 1.2365 steel to make complex forging dies that maintained excellent dimensional stability and surface integrity, even at operating temperatures above 900°C. The steel was used to produce a number of complex forging dies. Especially for precision forgings that require accurate dimensional control, the low distortion properties of H10 steel offer significant advantages, reducing the need for subsequent machining.

Hot extrusion tooling applications

X32CrMoV3-3 tool steel excels in metal extrusion tooling, particularly aluminium profile and copper alloy extrusion dies. A profile producer has extended the service life of its extrusion dies from the traditional 3 months to 5 months by using our die steel. The high wear resistance ensures that the die cavities maintain their precise geometry even at high pressures and temperatures, producing consistent, high-quality profile products.

High-temperature shear tool applications

Shear tools for cutting sheet metal, profiles and bars at high temperatures are another important application for H10/1.2365 steel. These applications require a material with excellent toughness and wear resistance at the same time, and FCS TOOL STEEL steels are precisely heat-treated to ensure sufficient toughness while maintaining high hardness, preventing chipping of the cutting edge and prolonging tool life.

Industry-Specific Applications

- Automotive Industry: die casting dies for aluminium alloy engine components; forging dies for driveline systems; thermoforming tools for chassis components;High-performance exhaust system dies; aerospace industry.

- Lightweight Alloy Precision Forging Dies: hot forming tools for turbine components; extrusion dies for structural components; high precision hot stamping tools.

- Consumer Electronics Industry: Smartphone and Tablet PC Heat Sink Extrusion Dies; Lightweight Aluminium Alloy Shell Die Casting Dies; Precision Connector Extrusion Tools; Durable Electronic Equipment Shell Hot Forming Dies

- Energy Industry: turbine parts forging moulds; power transmission parts extrusion tools; valve parts hot forging moulds; high-pressure equipment parts forming moulds.

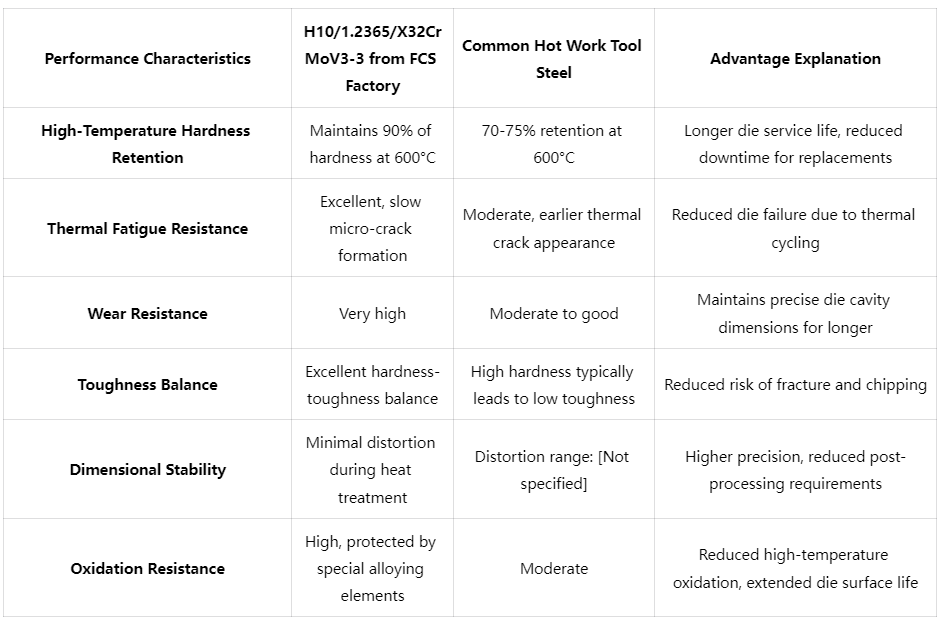

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Competitive Advantage Comparison

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Customer Success Stories

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Pricing Structure Information

H10 Tool Steel | 1.2365 | X32CrMoV3-3 Frequently Asked Questions

Q: Are H10/1.2365 and X32CrMoV3-3 exactly the same steel?

A: Yes, H10 (American AISI standard), 1.2365 (German DIN standard) and X32CrMoV3-3 (European EN standard) are different international standard designations for the same hot work mould steel. They have the same chemical composition and performance characteristics, and differ only in the naming standards.Q: What are the main advantages of H10 over other hot work mould steels (e.g. H13/1.2344)?

A: Compared to H13, H10/1.2365 has higher hot hardness and thermal fatigue resistance, making it particularly suitable for demanding applications such as aluminium die casting.H10 steel contains a higher proportion of molybdenum and vanadium, which forms a more stable carbide and has a greater ability to maintain its hardness at elevated temperatures. However, H13 offers better corrosion resistance due to its higher chromium content.Q: What is the difference between H10 tool steel and CrMoV hot work steel?

A: There is no difference, H10/1.2365 tool steel is a CrMoV hot work tool steel and the main alloying elements are chromium (Cr), molybdenum (Mo) and vanadium (V). The combination of these elements provides excellent hot hardness, wear resistance and resistance to thermal fatigue.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |