1.2713 Tool Steel | L6 | 55NiCrMoV6

In modern manufacturing, the performance of moulds and tools has a direct impact on productivity and product quality. Ordinary steels often suffer from premature wear, deformation or fracture under high strength, high temperature or complex working conditions, leading to frequent downtime for repairs and replacements and significantly increasing production costs.

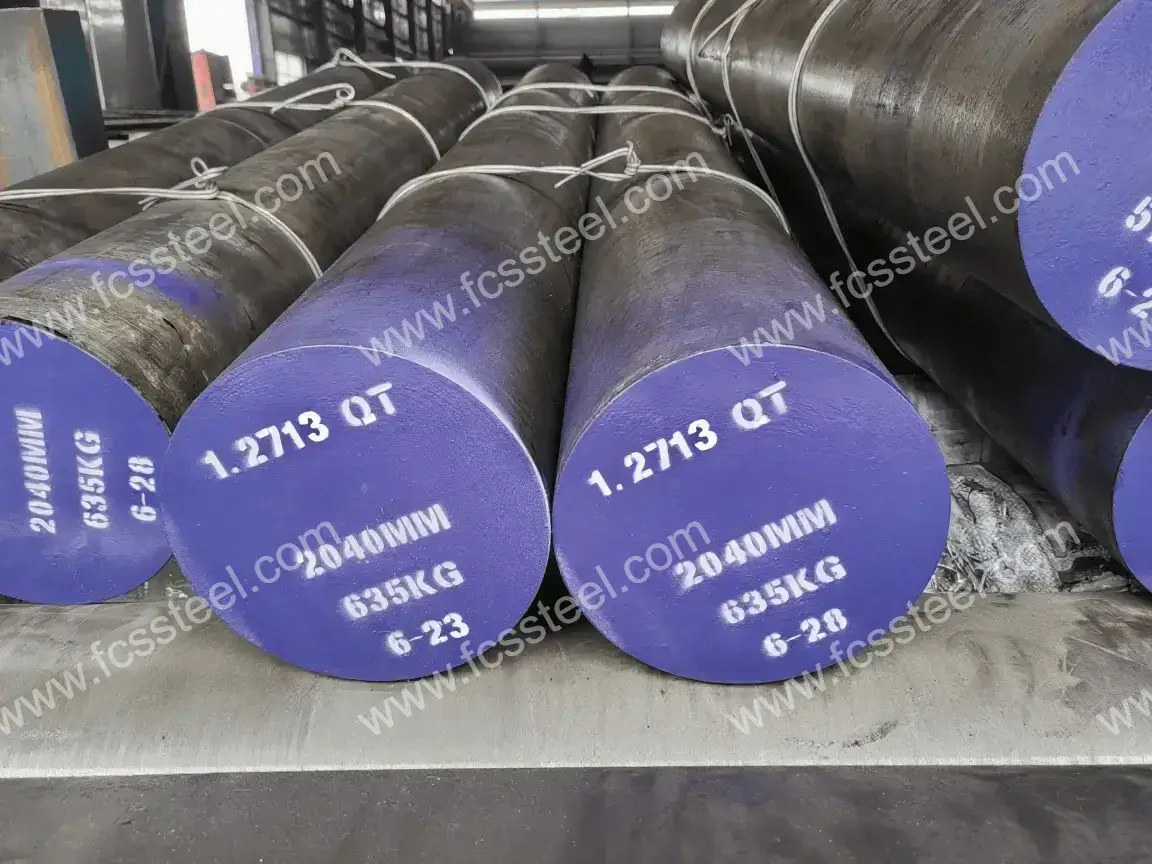

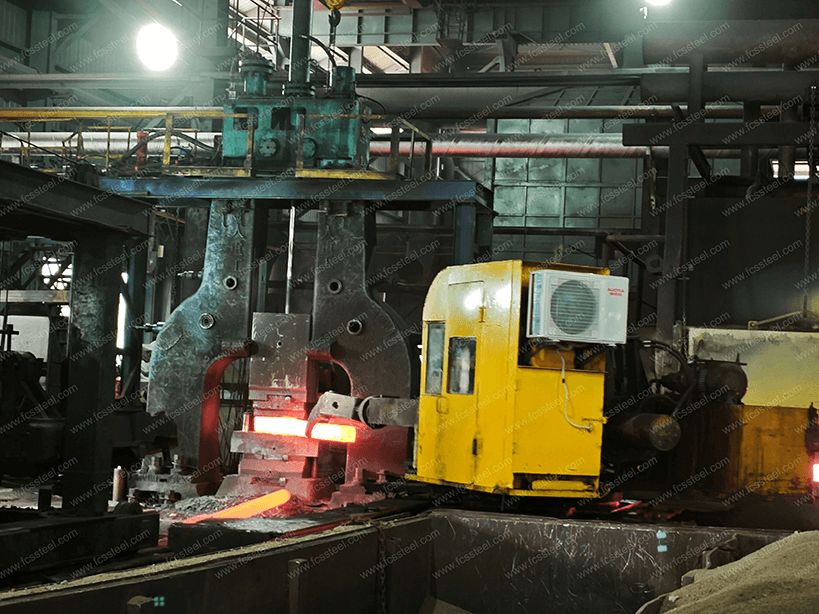

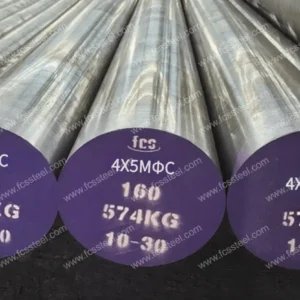

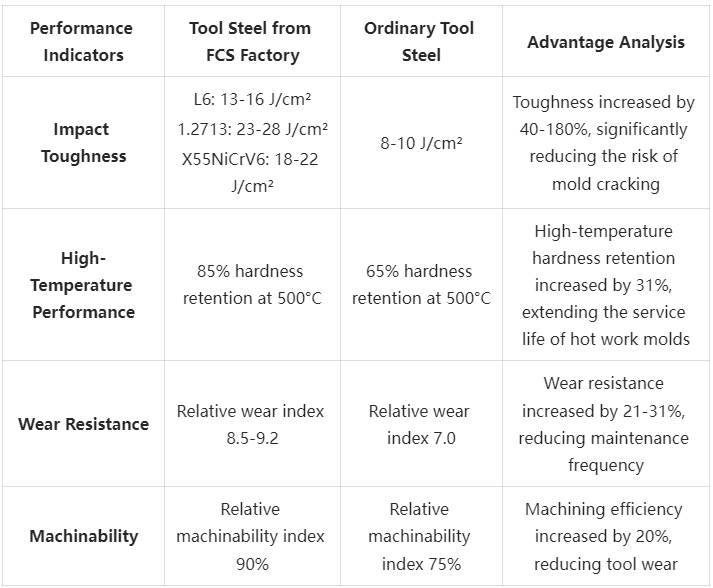

FCS Factory offers a range of L6, 1.2713 and X55NiCrV6 high performance tool steels with optimised chemical composition ratios and advanced heat treatment processes to achieve the perfect balance of wear resistance, toughness and thermal stability. These speciality steels maintain excellent performance under extreme conditions, significantly extending tool life.

Customers using FCS Factory’s tool steels have seen an average increase in mould life of 40-60%, a 35% reduction in downtime and an increase in productivity of more than 25%, providing a reliable material base for precision manufacturing. As a specialist tool steel manufacturer, FCS TOOL STEEL offers a full range of services from standard specifications to full customisation.

1.2713 Tool Steel | L6 | 55NiCrMoV6 Product Introduction

L6 Tool Steel (American Standard ASTM)

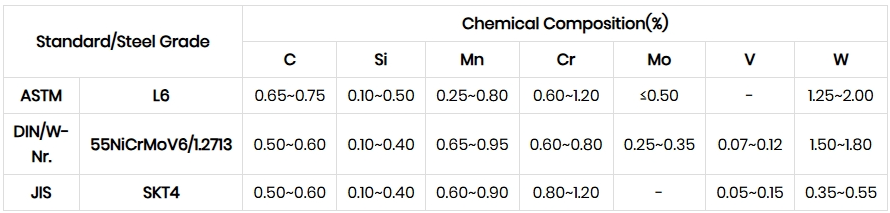

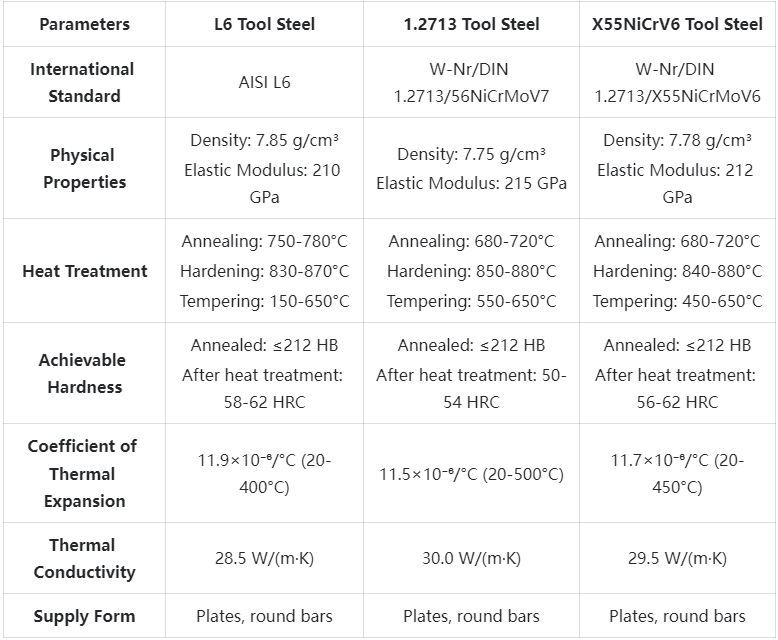

Composition and Basic Properties: L6 tool steel is an oil-hardening, chromium-nickel tool steel with a typical composition of carbon (0.65%-0.75%), nickel, and chromium (0.60%-1.20%), supplemented by manganese (0.25%-0.80%) and traces of molybdenum (≤ 0.50%).

Heat treatment and properties: hardness of 40-54 HRC after oil quenching (816-843°C) and low-temperature tempering, combining high toughness with moderate wear resistance (industrial rating 2/6). The hardenability is excellent and large cross sections can be hardened uniformly, but strict temperature control is required to avoid cracking and rapid cooling is required after tempering.

1.2713 Tool Steel (DIN, equivalent to 55NiCrMoV6)

Composition and Physical Properties: 1.2713 tool steel is a nickel-chromium-molybdenum-vanadium alloyed tool steel, with a composition of carbon (0.50-0.60%), nickel, chromium (0.60-0.80%), molybdenum (0.25-0.30%) and molybdenum (0.25-0.30%). 0.25%-0.35%) and vanadium (0.07%-0.12%).

Heat treatment and micro-control: oil quenching at 830-860°C, hardness after tempering varies with the temperature gradient (approx. 54 HRC at 200°C tempering, approx. 51 HRC at 300°C). Its high hardenability supports hardness uniformity over large sections (300 mm thickness), but it is sensitive to smelting impurities (phosphorus and sulphur ≤ 0.030%) and white point defects need to be controlled.

55NiCrMoV6 tool steel (German DIN, composition approximates 1.2713)

Composition and property correlation: X55NiCrV6 tool steel is a high-nickel-chromium-vanadium alloy steel, with a typical composition of carbon (0.50%-0.60%), nickel, chromium (0.60%-0.80%), vanadium (0.07%) 0.07%-0.12%) and vanadium (0.07%-0.12%), differing from 1.2713 by the absence of molybdenum.

Process characteristics: oil quenching at 830-870°C, hardness gradient after tempering similar to 1.2713 (tempered hardness 47-56 HRC at 160-300°C). The need to improve purity by electroslag remelting (ESR) and the low heat treatment distortion rate make it suitable for precision machining.

1.2713 Tool Steel | L6 | 55NiCrMoV6 Types and Options

The table below shows the size range, surface condition and tolerance details forL6/1.2713/55NiCrMoV6 Tool Steel:

1.2713 Tool Steel | L6 | 55NiCrMoV6 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- L6/1.2713/55NiCrMoV6 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

1.2713 Tool Steel | L6 | 55NiCrMoV6 Chemical Composition

1.2713 | L6 Tool Steel | 55NiCrMoV6 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

1.2713 Tool Steel | L6 | 55NiCrMoV6 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

1.2713 Tool Steel | L6 | 55NiCrMoV6 Technical Specifications

1.2713 Tool Steel | L6 | 55NiCrMoV6 Product Applications

L6 Tool Steel Application Scenarios (Impact Performance Preferred)

With its excellent balance of toughness and hardness, L6 tool steel is particularly suited to application scenarios where impact loading is required. In the automotive industry, our L6 tool steel is widely used in the production of large stamping dies that can withstand continuous high-speed stamping operations without cracking.

After an auto parts manufacturer used our L6 tool steel to make the body side plate stamping die, the die life was increased from 800,000 times to 1.35 million times, reducing the number of die maintenance times by 40% and significantly reducing the production downtime.

In addition, L6 tool steel also performs well in woodworking cutting tools, large shear knives and cold work moulds that require high toughness. A wood processing company uses band saws made from our L6 tool steel to cut hardwoods with 55% longer life than ordinary tool steel, significantly reducing replacement and maintenance costs.

1.2713 tool steel application scenarios (hot work performance preferred)

Designed for high temperature working environments, 1.2713 tool steel excels in hot forging, hot extrusion and die casting applications. Our 1.2713 tool steel is used in a wide range of aluminium alloy die casting moulds, where it maintains good hardness and resistance to thermal fatigue at sustained working temperatures of 500°C and above.

A die casting factory using our 1.2713 tool steel manufacturing aluminium alloy auto parts mould, achieve a continuous 80,000 times die casting without maintenance, than using ordinary hot work die steel to improve productivity by 30%, product qualification rate increased by 5 percentage points.

In addition, 1.2713 tool steel in the hammer forging die, hot extrusion die and plastic mould also has excellent performance. A heavy-duty forging plant uses our 1.2713 tool steel to manufacture hammer forging dies, and in the 1100 ℃ high-temperature forging environment, the service life is 45% higher than that of traditional dies, creating significant economic benefits for customers.

X55NiCrMoV6 Tool Steel Application Scenarios (Precision Performance Preferred)

55NiCrMoV6 tool steel is ideal for precision cold work moulds and precision measuring tools. The 55NiCrMoV6 tool steel we supply has high dimensional stability and excellent wear resistance, and performs well in precision stamping, precision forming and precision instrument manufacturing.

A precision electronic connector manufacturer uses our 55NiCrMoV6 tool steel to manufacture precision stamping moulds, which can achieve a dimensional accuracy of ±0.005mm, and maintains the original accuracy after 2 million consecutive production runs, which significantly improves product consistency.

In addition, 55NiCrMoV6 tool steel in high-precision gauges, precision cutting tools and high-load cold working moulds are also widely used. An aerospace parts manufacturer uses our 55NiCrMoV6 tool steel to manufacture precision forming moulds, and the deformation in the production process is 65% lower than that of ordinary tool steel, which greatly improves the product qualification rate.

1.2713 Tool Steel | L6 | 55NiCrMoV6 Competitive Advantage Comparison

1.2713 Tool Steel | L6 | 55NiCrMoV6 Customer Success Stories

1.2713 Tool Steel | L6 | 55NiCrMoV6 Pricing Structure Information

1.2713 Tool Steel | L6 | 55NiCrMoV6 Frequently Asked Questions

Q:How do I select the best tool steel for my application?

A:The choice depends on your specific application requirements. Consider the following factors: working temperature, type of load (impact, pressure, wear), batch size, precision requirements and budget. L6 tool steel is suitable for high impact applications, 1.2713 for high temperature working environments and X55NiCrMoV6 for precision applications. Our technical team can give you professional advice based on the application information you provide.Q:How do ESR and VAR processes improve the properties of tool steel?

A:Electroslag Remelting (ESR) and Vacuum Arc Remelting (VAR) are advanced processes that improve the purity of tool steel. These processes can reduce the amount of non-metallic inclusions by 60-80% and significantly improve fatigue strength and toughness. ESR/VAR tool steels are particularly suited for high-load, long-life, or safety-critical applications, and although more expensive, they are often more cost-effective over their entire life cycle.Q:What is the lead time for tool steel materials?

A:Lead times depend on material type, specification and quantity.Q:What factors affect the service life of tool steel?

A:The main factors affecting tool steel life include: proper material selection, quality of heat treatment, surface finish, operating temperature, load size, frequency of impacts, lubrication conditions, cooling effectiveness, frequency of maintenance, and operating practices. By optimising these factors, tool life can vary by a factor of 5-10 FCS TOOL STEEL offers a full range of technical advice to help customers maximise the performance of their tool steel.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |