H13 Tool Steel | 1.2344 | X40CrMoV5-1

As a high-quality chromium-molybdenum-vanadium alloy, 1.2344 achieves outstanding performance by optimizing its chemical composition. The high-quality JIS SKD61 Steel of FCS Factory has excellent thermal fatigue resistance, outstanding toughness and stable cutting performance, which can maximize the mold life and production efficiency. Designed for outstanding performance in aluminum die-casting, injection molding and hot forging operations.

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Product Introduction

1.2344 tool steel is a commonly used hot work mould steel, belonging to the German DIN standard (W-Nr. numbering system) in the grade, corresponding to the international widely used H13 type of mould steel (H13 in the U.S. ASTM standard, SKD 61 in the Japanese JIS standard, and 4Cr5MoSiV1 in the Chinese GB standard.) It has excellent thermal strength, thermal fatigue resistance, wear resistance and hardenability. It has excellent hot strength, hot fatigue resistance, wear resistance and hardenability, and is mainly used in moulds and parts subjected to shock and cyclic loads at high temperatures.

High-temperature mould applications pose a major challenge to tool engineers. Premature failure due to thermal fatigue, cracking and wear can result in costly downtime and inconsistent part quality. FCS Tool Steel's premium SKD61 tool steel addresses these challenges with an optimised chromium-molybdenum-vanadium alloy composition. With full certification and in-stock inventory, FCS Factory can help you reduce lead times and increase productivity.

H13 Tool Steel | 1.2344 | X40CrMoV5-1Types and Options

The table below shows the size range, surface condition and tolerance details for H13/1.2344/X40CrMoV5-1 Tool Steel:

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- H13/1.2344/X40CrMoV5-1 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

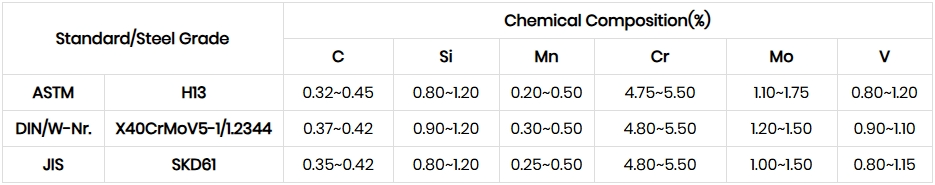

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Chemical Composition

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

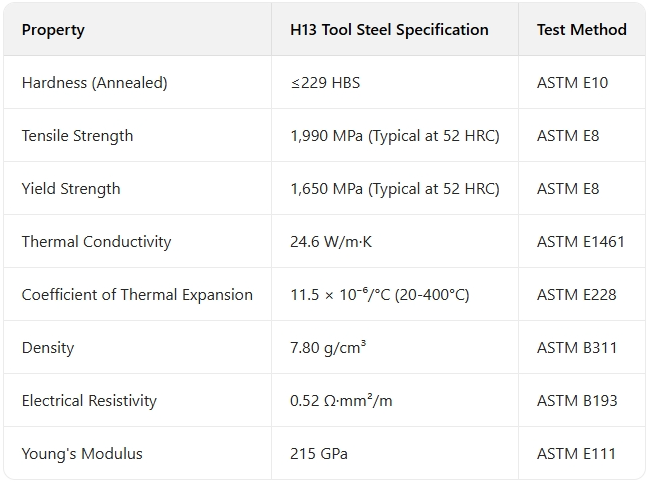

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Technical Specifications

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Product Applications

Cold-working moulds

- Stamping moulds: used for blanking steel plates and stainless steel plates with a large thickness (e.g., more than 2mm), such as automotive coverings stamping moulds, electrical machinery, silicon steel sheet stamping moulds, etc. Stamping moulds: used for stamping steel plates with large thickness (e.g. above 2mm), such as stamping moulds for automobile coverings, stamping moulds for silicon steel sheets of electric motors, etc. Due to its high wear resistance and high strength, it can withstand long time stamping load and reduce the risk of mould wear and breakage.

- Cold heading moulds: in the cold heading process of bolts, nuts and other fasteners, the moulds need to withstand very high pressure and friction. 1.2379 tool steel's high hardness and wear resistance make it an ideal material for cold heading moulds, which ensures the dimensional accuracy and surface quality of the fasteners.

- Cold Extrusion Dies: Used for the manufacture of cold extruded parts of non-ferrous metals such as aluminium alloys and copper alloys, such as gears and bearing rings. The good toughness and anti-fatigue properties of the steel, so that it can work stably in the complex stress state.

Gauges and Cutting Tools

Gauges: make high-precision gauges, plug gauges, card gauges, etc., used to measure the size and shape accuracy of workpieces. Because of its good dimensional stability and high wear resistance, it can maintain the accuracy of the gauge for a long time.

Cutting tools: such as broaches, reamers, taps, etc., are used for machining high-precision holes and threads. In cutting harder materials, 1.2379 tool steel's high wear resistance and tempering softening resistance can significantly improve tool life.

Other Areas

In some of the need for high hardness, wear resistance and a certain degree of toughness in the manufacture of mechanical parts, can also be used 1.2379 tool steel, such as wear-resistant liner, guide pillar guide bushing.

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Comparison Summary

Comparison Summary

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Customer Success Stories

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Pricing Structure Information

H13 Tool Steel | 1.2344 | X40CrMoV5-1 Frequently Asked Questions

Q: What is the difference between 1.2344 tool steel and 1.2379 tool steel?

A: 1.2344 has good thermal strength and toughness, and can maintain good strength and hardness at high temperatures, which is suitable for working in hot work environments with repeated heating and cooling. 1.2379 has excellent wear resistance and dimensional stability, and is able to withstand high-stress and high-wear working conditions at ambient temperatures, but has a lower toughness compared to 1.2344. 1.2379 has excellent wear resistance and dimensional stability, and is able to withstand high stress and high wear at ambient temperature, but has a lower toughness than 1.2344. 1.2344 is mainly used in the field of hot work molds, such as aluminum alloy die casting molds, hot forging molds, hot extrusion molds, etc. 1.2379 is mainly used in the field of cold work molds, such as blanking molds, cold heading molds, cold extrusion molds, deep drawing molds, etc. 1.2379 is mainly used in the field of cold work molds, such as blanking molds, cold heading molds, cold extrusion molds, deep drawing molds, etc.

Q: How does SKD61 compare to H13 tool steel?

A: SKD61 and H13 are equivalent grades under different standards (JIS vs. AISI). However, our premium SKD61 is cleaner, more stable and has better heat treatment response than standard commercial H13. The chemical composition ranges are similar, but our tighter control of trace elements and advanced machining processes result in superior performance.

Q: What is the difference between your standard SKD61 and ESR variants?

A: Our SKD61-ESR undergoes additional electroslag remelting to significantly improve cleanliness and reduce non-metallic inclusions. This provides superior polishability, enhanced fatigue resistance and a more consistent heat treat response - which is especially valuable for complex, highly polished moulds or safety critical components.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |