| Shape | Pocess | Size range | Surface | Tolerance |

| Flat Bar | Hot Rolled | Thickness: 10-400mm

Width: 200-800mm Length: 3000-5800mm |

Black;

Sandblasted |

Thickness :0-+2MM

Width:0-+5MM/0-+10MM |

| Hot Forged | Thickness: 50-500mm

Width: 50-1500mm Length: 3000-5800mm |

Black | Thickness:+2-+5MM

Width:0-+5MM/0-+10MM |

|

| Turned/Machined/Milled/Bright | Thickness :0-+2MM

Width:0-+5MM/0-+10MM |

|||

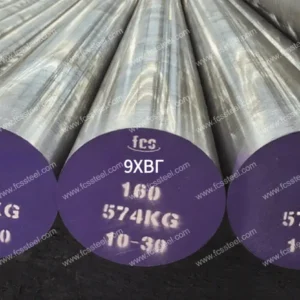

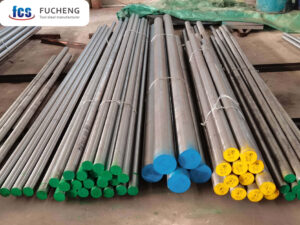

| Round Bar

|

Hot Rolled | Diameter:10-65mm

Length:3000-5800mm |

Black | 0-+2MM |

| Turned/Machined | 0-+2MM | |||

| Hot Forged | Diameter:70-700mm

Length:3000-5800mm |

Grinded | 0-+5MM/+2-+5MM | |

| Turned/Machined/Milled/Bright | 0-+2MM |

1.2379 Cold Work Steel |X155CrVMo12-1 | D2

1.2379/X155CrVMo12-1/D2 tool steel represents the pinnacle of high-carbon and high-chromium cold working tool steel technology.1.2379/X155CrVMo12-1/D2 steel features excellent wear resistance, good compressive strength and medium toughness, making it an ideal choice for automobiles. The preferred material for the most demanding cold working applications in the electronics and precision manufacturing industries.

The FCS factory not only has a large inventory of D2 tool steel plates and round bars, but also offers custom cutting services. If you have any requirements for heat treatment, we can also provide you with professional consulting services.

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 product introduction

1.2379/X155CrMoV12-1 is a tool steel grade in the German Standard (DIN), which belongs to cold work mould steel. It is also a high-carbon, high-chromium cold working tool steel. Its corresponding Chinese national standard grade is Cr12Mo1V1, American ASTM/AISI grade is D2, Japanese JIS grade is SKD11. Its smelting and manufacturing methods for EF + LF + VD + Hot rolled / Hot Forged + Annealed. the steel has a high hardness, wear resistance and toughness, widely used in industrial applications requiring long time wear resistance, as well as cold work mould manufacturing and other fields.

In conclusion, 1.2379 tool steel is a kind of cold work mould steel with excellent performance, through reasonable chemical composition design and heat treatment process, it can meet the requirements of different working conditions. In practical application, according to the specific conditions of use and processing requirements, select the appropriate heat treatment process and processing methods, in order to give full play to its performance advantages.

ASTM American Standard D2 tool steel (European grade 1.2379) is the ideal solution for manufacturers to meet the challenges of tool wear in high-stress applications. While standard tool steels fail prematurely under intense use, resulting in high downtime and replacement costs, D2 tool steel offers excellent wear resistance and dimensional stability even in the most demanding environments.

As a specialised supplier of D2 tool steel, FCS Factory stocks a wide range of plate and round bar sizes to ensure immediate availability for urgent production requirements. Our value-added services include precision custom cutting to your exact specifications, as well as expert heat treating guidance to achieve optimum hardness (≤255 HBS) for your specific application.

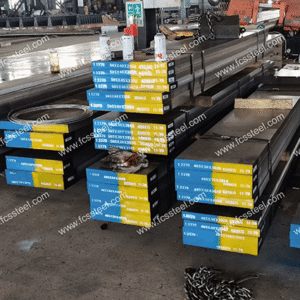

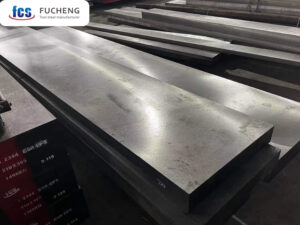

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Product Types and Options

FCS Factory offers a premium 1.2379/X155CrVMo12-1, D2 tool steel that combines high carbon and high chromium compositions, allowing it to maintain its edge and shape over thousands of production cycles. The balanced composition provides excellent hardenability while minimising distortion during heat treatment - a key factor in precision tooling applications.

Whether you manufacture stamping dies, industrial cutting blades or wear parts, FCS Factory's 1.2379/X155CrVMo12-1, D2 tool steel delivers the performance reliability and extended tool life you need, and supports your global manufacturing facilities with convenient international shipping.

Below is a table showing details of 1.2479,D2,X155CrVMo12-1 tool steel size range, surface condition and tolerances:

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 1.2379,X155CrVMo12-1,D2 Cold work Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Chemical composition

| Standard/Steel Grade | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | V | ||

| ASTM | D2 | 1.40~1.60 | ≤0.60 | 0.10~0.60 | 11.00~13.00 | 0.70~1.20 | 0.70~1.10 |

| DIN/W-Nr. | X153CrMo12/1.2379 | 1.45~1.60 | ≤0.60 | 0.10~0.40 | 11.00~13.00 | 0.70~1.00 | 0.70~1.00 |

| JIS | SKD11 | 1.40~1.60 | ≤0.40 | ≤0.40 | 11.00~13.00 | 0.80~1.20 | 0.20~0.50 |

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 heat treatment process

1.Annealing

Process parameters:

Heating temperature: 800-850 ℃, holding time 2-4 hours, with the furnace cooling to below 500 ℃, and then air-cooled.

Hardness after annealing: ≤ 255HBS.

2.Quenching

Process parameters:

Heating temperature: 1000-1050 ℃ (commonly used 1020-1040 ℃), holding time according to the size of the workpiece to determine, generally 30-60 minutes.

Cooling: oil cooling or air cooling (for small size or simple shape of the workpiece), large workpieces can be graded quenching (in the 260-300 ℃ salt bath cooling for a period of time and then air-cooled), in order to reduce the quenching stress, to prevent deformation and cracking.

3.Tempering

Process parameters:

low-temperature tempering: 150-250 ℃, insulation 2-3 hours, air-cooled, tempered hardness of 58-62HRC, for molds requiring high hardness and wear resistance.

Medium temperature tempering: 300-500 ℃, insulation 2-3 hours, air-cooled, tempered hardness of 50-58HRC, can improve the toughness, suitable for molds subject to impact load.

High-temperature tempering: 500 ℃ or more, insulation 2-3 hours, air-cooled, tempered hardness 45-50HRC, mainly for the need for higher toughness of the occasion.

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

Tempering must be sufficient to ensure the elimination of internal stresses to avoid mold failure due to stress release during use. For large molds or workpieces with complex shapes, multiple tempering can be used.

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Quality Inspection

1.Surface Condition Inspection

FCS factory has a very strict quality inspection team, we will carefully check the surface condition of each piece of tool steel to ensure that the steel surface is free from cracks, folds, knots, oxidized skin, pitting, scratches and other defects.

2.Chemical Composition Testing

To verify whether the content of alloying elements meets the standard requirements and to safeguard the basis of the mechanical properties of the material. We will let the staff use full-spectrum direct reading spectrometer to analyze multiple elements at the same time. Sampling needs to remove the surface oxidation layer, using a block specimen to stimulate the test.

3.Dimension and Tolerance Inspection

FCS factory will use professional measuring tools to inspect the dimensions and tolerances of the steel to ensure compliance with the customer's contract requirements. Corresponding gauges will be selected according to the dimensional accuracy requirements, including tape measure, high-precision vernier calipers (0.02mm), micrometers (0.001mm), and special inspection gauges. Inspection items cover: diameter, thickness, width, length, hole diameter, chamfering dimensions, etc., to ensure that the tolerances and dimensions meet the contract requirements.

4.Hardness test

Our FCS factory will use professional hardness tester to test the hardness of steel to ensure that it meets the customer's contract requirements.

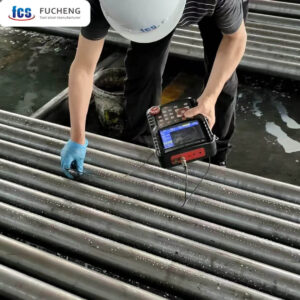

5.Ultrasonic Testing

Ultrasonic Testing Standard (UT Test Standard) is: Sep 1921-84 Class3 D/d,E/e.

FCS factory uses ultrasonic testing equipment to detect macro defects inside the material (such as cracks, shrinkage holes, inclusions, white spots, etc.), and every piece of round steel and plate will be examined by a second flaw detection test before shipment to ensure that the quality is qualified before shipment.

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

FCS factory will use the comparative method to determine the austenite grain size by comparing the microstructure of the specimen with the standard rating chart, to ensure that it meets the customer's requirements.

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Technical Specifications

| Property | AISI D2 / 1.2379/X153CrMo12 Specification | Test Method |

| Density | 7.7 g/cm³ | ASTM B311 |

| Hardness (Annealed) | ≤255 HB | ASTM E10 |

| Compressive Strength | 2200 MPa (at 60 HRC) | ASTM E9 |

| Tensile Strength | 1700-1800 MPa (at 60 HRC) | ASTM E8 |

| Elastic Modulus | 210 GPa | ASTM E111 |

| Thermal Conductivity | 20 W/m·K | ASTM E1461 |

| Coefficient of Thermal Expansion | 10.4 x 10⁻⁶ /K (20-100°C) | ASTM E228 |

| Machinability Rating | 35-40% (relative to 1% carbon steel) | Comparative Testing |

| Grindability Rating | Good | Comparative Testing |

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Product Applications

Cold working moulds: such as stamping moulds (for punching, bending, deep drawing and other processes), cold heading moulds, cold extrusion moulds, etc., which can be used to process metal materials with higher hardness, such as stainless steel, high strength steel, etc.

Gauges and tools: to make high-precision gauges, such as calipers, micrometers, etc.; as well as tools, such as cutting tools, broaches, etc., for occasions requiring high wear resistance and precision

Cold-working moulds

Stamping moulds: used for blanking steel plates and stainless steel plates with a large thickness (e.g., more than 2mm), such as automotive coverings stamping moulds, electrical machinery, silicon steel sheet stamping moulds, etc. Stamping moulds: used for stamping steel plates with large thickness (e.g. above 2mm), such as stamping moulds for automobile coverings, stamping moulds for silicon steel sheets of electric motors, etc. Due to its high wear resistance and high strength, it can withstand long time stamping load and reduce the risk of mould wear and breakage.

Cold heading moulds: in the cold heading process of bolts, nuts and other fasteners, the moulds need to withstand very high pressure and friction. 1.2379 tool steel's high hardness and wear resistance make it an ideal material for cold heading moulds, which ensures the dimensional accuracy and surface quality of the fasteners.

Cold Extrusion Dies: Used for the manufacture of cold extruded parts of non-ferrous metals such as aluminium alloys and copper alloys, such as gears and bearing rings. The good toughness and anti-fatigue properties of the steel, so that it can work stably in the complex stress state.

Gauges and Cutting Tools

Gauges: make high-precision gauges, plug gauges, card gauges, etc., used to measure the size and shape accuracy of workpieces. Because of its good dimensional stability and high wear resistance, it can maintain the accuracy of the gauge for a long time.

Cutting tools: such as broaches, reamers, taps, etc., are used for machining high-precision holes and threads. In cutting harder materials, 1.2379 tool steel's high wear resistance and tempering softening resistance can significantly improve tool life.

Other Areas

In some of the need for high hardness, wear resistance and a certain degree of toughness in the manufacture of mechanical parts, can also be used 1.2379 tool steel, such as wear-resistant liner, guide pillar guide bushing.

1.2379 Cold Work Steel |X155CrVMo12-1 | D2 Competitive Advantage Table

| Characteristics | 1.2379/X155CrVMo12-1/D2 Tool Steel of FCS Factory | Standard Tool Steel | High - end Competitor Products |

| Wear Resistance Rating | 9/10 | 6/10 | 8/10 |

| Inventory Availability | Large stock | Limited stock | Varies by supplier |

| Heat Treatment Guidance | Comprehensive guidance & support | Basic guidance | Limited support |

| Technical Consultation | Free expert consultation | Limited | Charged |

| Material Certification | Standard full certification | Provided as needed | Provided as needed |

| International Shipping | Global logistics network | Limited destinations | Regional focus |

Customer Success Stories

Skip the middleman link, source factory purchasing, reduce purchasing cost and improve market competitiveness.

Pricing Structure Information

Serving the world, whole cabinet sales, factory wholesale price.

Frequently Asked Questions

Q: What are the differences between steel grades 1.2379 and SKD11?

A: 1.2379 is the German standard, while SKD11 is the Japanese standard. The two have similar components, performance and application scenarios.Q: What are the differences between Standard 1.2379 and electroslag remelting grade?

A: Electroslag remelting grade 1.2379 has higher purity, less segregation and better performance, while the standard grade is slightly inferior.Q: What are the differences between D2 and A2 tool steels in mold applications?

A: Although both are general-purpose tool steels, D2 has a higher carbon and chromium content than A2, thus offering better wear resistance and edge retention. However, A2 has slightly better toughness. For applications that mainly focus on abrasive wear, D2 is superior. For applications with impact loads or shocks, A2 may be more suitable.Q: How can I determine the thickness of the D2 sheet required for my application?

A: The appropriate thickness depends on multiple factors, including unsupported span, applied force, required stiffness and potential deflection. Our technical team can assist in the calculation based on your specific application parameters.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |