Tool steel selection and heat treatment have a direct impact on the performance and lifespan of industrial tooling. Among the most widely used grades in tooling applications are 1.2379 (D2 equivalent) and 1.2344 (H13 equivalent). Both are high-performance steels, but they differ in composition, application scope, and most importantly—their annealing processes. Understanding the differences in annealing is critical for toolmakers, wholesalers, and traders who aim to optimize cost, performance, and service life.

This article will provide a detailed comparison of the annealing process for 1.2379 and 1.2344 tool steel, followed by practical considerations for industrial buyers. We will also introduce the advantages of sourcing these grades from FCS Tool Steel, a trusted global supplier.

Overview of 1.2379 and 1.2344 Tool Steels

Before diving into the annealing process, it’s important to understand the characteristics of these two steels:

1.2379 Tool Steel (D2 equivalent)

A high-carbon, high-chromium cold work steel with excellent wear resistance, dimensional stability, and good compressive strength. Commonly used in blanking dies, forming tools, and cutting blades.

1.2344 Tool Steel (H13 equivalent)

A chromium-molybdenum-vanadium hot work steel with excellent thermal fatigue resistance, toughness, and high-temperature strength. Widely applied in die casting dies, extrusion tools, and hot forging dies.

Purpose of Annealing in Tool Steels

Annealing is a controlled heat treatment process used to soften the steel, improve machinability, and relieve internal stresses. For tool steels like 1.2379 and 1.2344, proper annealing ensures:

- Uniform microstructure

- Easier machining before hardening

- Reduction in risk of cracking during quenching

- Longer tool life after final heat treatment

- Although both grades require annealing, their exact parameters differ due to their distinct alloy compositions.

1.2379 Tool Steel Annealing Process

For 1.2379, the annealing process is designed to reduce hardness to around 200–230 HB while maintaining a fine, consistent microstructure.

Typical Annealing Steps:

- Heating:Heat the steel slowly and uniformly to 850–900°C.

- Soaking:Hold at the target temperature for at least 2 hours per 25 mm of thickness to ensure temperature uniformity throughout the cross-section.

- Cooling:Cool slowly in the furnace at a controlled rate (max 10°C per hour) down to around 650°C, then allow air cooling to room temperature.

Key Notes:

- Avoid overheating as it can cause grain coarsening and reduce wear resistance.

- Stress relieving may be performed at 600–650°C prior to annealing if heavy machining has been done.

1.2344 Tool Steel Annealing Process

1.2344 is a hot work tool steel, and its annealing cycle focuses on softening while preserving toughness and high-temperature stability.

Typical Annealing Steps:

- Heating:Heat slowly to 850–880°C.

- Soaking:Hold for 1–2 hours per 25 mm of section thickness.

- Cooling:Cool in the furnace at a controlled rate of 10°C per hour until reaching around 600°C, then air cool to room temperature.

Key Notes:

- The slower cooling rate helps prevent the formation of undesirable structures like bainite or pearlite with excessive hardness.

- Post-annealing hardness typically falls between 180–200 HB.

Key Differences in Annealing Parameters

While both steels share similar furnace cooling rates, their annealing temperature ranges differ due to their alloying elements and intended applications.

- Temperature Range:1.2379 requires slightly higher temperatures (850–900°C) compared to 1.2344 (850–880°C).

- Application Impact:The higher chromium and carbon content in 1.2379 demands precise temperature control to avoid carbide network formation, while 1.2344’s molybdenum and vanadium content necessitate a balance between softness and high-temperature stability.

- Machinability After Annealing:1.2379 offers superior wear resistance but is more challenging to machine compared to 1.2344, which is easier to work with after annealing.

Practical Considerations for Industrial Buyers

For wholesalers, stockists, and traders dealing in tool steel, understanding the annealing process offers two main benefits:

- Quality Control:Ensures supplied steel is in the correct soft-annealed condition, avoiding extra processing costs for the end-user.

- Customer Support:Providing correct annealing parameters builds trust with toolmakers and manufacturing partners.

Buyers should always verify:

- Annealing certificate or hardness test report

- Supplier’s consistency in furnace temperature control

- Compliance with international standards (DIN, ASTM, JIS, GB)

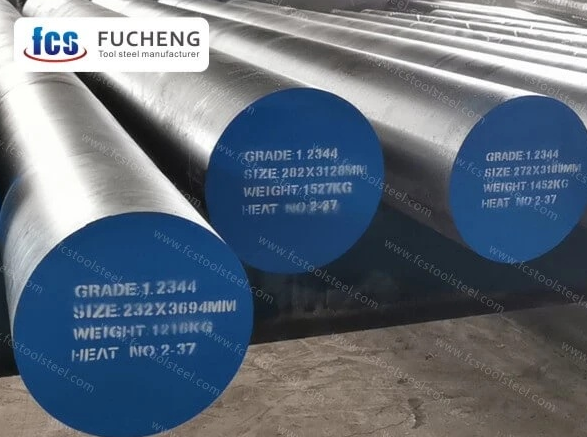

Why Choose FCS Tool Steel for 1.2379 and 1.2344

FCS Tool Steel is an experienced and trusted supplier specializing in high-grade tool steels for global markets. Our 1.2379 and 1.2344 products stand out because of:

- Guaranteed Soft Annealed Condition:All steel is delivered in a precise annealed state for maximum machinability and minimal stress.

- Extensive Inventory:Round bars, flat bars, and plates in multiple dimensions, ready for immediate shipment.

- Competitive Pricing for Bulk Orders:Attractive rates for wholesalers, distributors, and traders.

- Strict Quality Control:Each batch undergoes furnace temperature monitoring, hardness testing, and metallographic inspection.

- Global Logistics Capability:Fast delivery to Asia, Europe, the Middle East, and the Americas.

- Technical Support:Expert advice on heat treatment, machining, and application optimization.

By choosing FCS Tool Steel, buyers secure not just a material, but a reliable supply chain partner capable of meeting urgent and large-scale orders.

Conclusion

While 1.2379 and 1.2344 tool steels differ in composition and application, both require precise annealing to ensure machinability, dimensional stability, and optimal performance in tooling. 1.2379 offers exceptional wear resistance for cold work applications, whereas 1.2344 excels in high-temperature environments.

For industrial buyers—especially wholesalers and traders—partnering with a supplier who understands and controls the annealing process is crucial. FCS Tool Steel not only provides correctly annealed 1.2379 and 1.2344 but also ensures competitive pricing, global delivery, and technical expertise.