Introduction:

Premium pricing needs solid reasons. German 1.2316 (X38CrMo16) costs 1.7–2.0 times more than equivalent ESR-processed steel from other regions. General ESR tool steel runs 6–20 USD/kg globally. German mills stay at the top of that range or go higher. Non-ESR regional grades drop to 0.5–2.5 USD/kg. But these don’t work well for mirror-finish mold jobs.

That price gap gets you three real benefits: inclusion cleanliness, hardness consistency, and batch-to-batch repeatability. Each one saves money in your workshop. Plus, they cut production risks.The difference shows up in real work, not just on paper.

This guide shows you the industrial processes behind German 1.2316. You’ll see their quality systems and R&D partnerships that make their steel different. Plus, you’ll learn when that quality premium actually makes sense for your specific needs.

Germany’s Industrial Role

Germany produces approximately 35.5 million tons of crude steel each year. They consistently rank in the global top 10. In late 2025, their monthly output remained strong, accounting for nearly 29% of the entire EU27‘s production. Germany leads Europe’s steel manufacturing.

Germany takes a big share in high-value segments. These include tool steels, mold steels, and ultra-clean alloy grades. These processes define Germany’s niche. They don’t chase bulk tonnage. They chase purity at the microscopic level. Compositional precision is what they compete on.

High-end 1.2316 quality standards &delivery status

German mills control composition better than international standards demand. DIN ISO 4957 sets the baseline ranges. Top German producers tighten those limits on their own.

1. Chemical Composition: Beyond Standard Limits

1.2316 (X38CrMo16) follows these core ranges under ISO 4957:

| Element | Carbon (C) | Chromium (Cr) | Molybdenum (Mo) | Silicon (Si) | Manganese (Mn) |

| Range (%) | 0.33 – 0.45 | 15.5 – 17.5 | 0.80 – 1.30 | ≤ 1.0 / 1.5* | ≤ 1.0 / 1.5* |

German high-end producers go further. They set stricter limits on harmful elements:

- Phosphorus: Standard allows ≤0.03–0.04%. German mills keep it ≤0.025–0.03%.

- Sulfur: Standard permits ≤0.03–0.04%. ESR/VAR-processed steel cuts this to ≤0.005–0.010%. Premium brands go below ≤0.003%.

70–80% of German tool and mold steel production uses electroslag remelting. ESR-grade 1.2316 shows oxygen content below 8 ppm. Sulfur stays under 0.003%. The slag layer traps non-metallic inclusions. Microsegregation reduces. Center porosity vanishes.

2. Ultrasonic Testing Grades: Two-Tier Cleanliness

German mills offer at least two UT quality levels:

| Feature | Grade 2 (Standard) | SEP 1921 Group 3 Class E/e (High-Clean) |

| Primary Application | General mold engineering | Mirror polishing & precision plastic molds |

| Internal Defect Limit | Standard industrial tolerance | Zero defects > 1 mm |

| Surface Finish ($Ra$) | Standard machining levels | 0.015 – 0.02 µm (Mirror finish) |

| Polishing Quality | General clarity | No pitting or drag marks |

| Scanning Scope | Sectional or standard sampling | 100% full-section (both directions) |

| Technical Metrics | Basic mill standards | Quantified echo heights & spacing gaps |

3. Hardness Uniformity in Large Sections

German producers keep cross-section hardness variation tight. Premium 1.2316 blocks show hardness change within ±1 HRC across the whole section. Industry standard allows ±2 HRC. This matters for large cavity inserts. Even hardness gives you steady tool life. Plus, heat treatment won’t cause surprise warping.

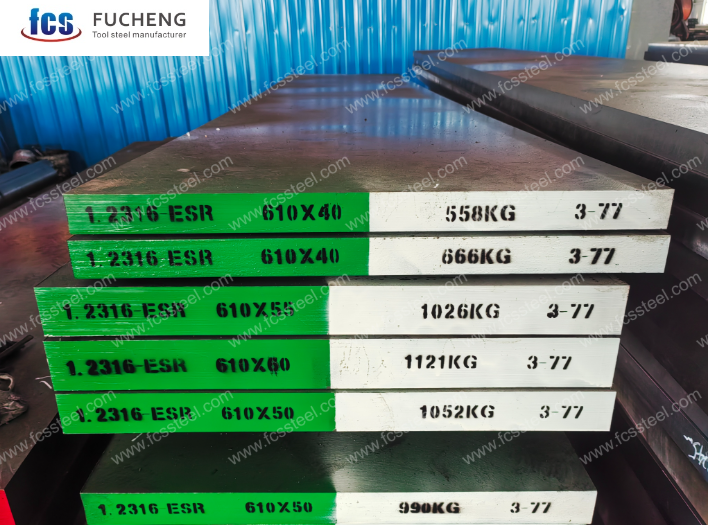

4. Delivery Conditions: Annealed or Prehardened

| Feature | Annealed (Soft) State | Prehardened Blocks | Full Quench & Temper |

| Typical Hardness | 190–230 HB | 280–330 HB (~28–32 HRC) | 48–54 HRC |

| Material Status | Stress-relieved; soft for machining | Ready for immediate use | Peak hardness via heat treat |

| Primary Benefit | Ideal for heavy milling of complex shapes | Eliminates post-machining heat treat time | Maximum wear resistance |

| Best Use Case | Precision parts before final hardening | Injection molds with moderate wear needs | High-pressure/abrasive environments |

| Surface Options | Machining then hardening | Direct use or surface coating | Compatible with Nitriding |

Metallurgical processes that ensure the quality stability

German steel mills turned digital process control into their competitive edge decades ago. Composition specs matter. But consistent reproduction of those specs across thousands of tons is what separates elite producers from the rest.

With an annual output of about 35.5 million tons, Germany produces one-quarter of the EU’s total steel. Here’s what matters more: over 50% gets exported—mostly high-value specialty grades. Your steel crosses borders to demanding customers. Process stability becomes mandatory, not optional.

1. Electric Arc and Basic Oxygen: The Foundation Mix

Germany’s steelmaking split stays stable: about 30% electric arc furnace (EAF) steel and 70% basic oxygen furnace (BOF) steel. Open-hearth processes died out years ago. This dual-track setup supports different quality tiers.

For 1.2316 and similar mold steels, EAF routes take the lead. Electric furnaces give you tighter scrap selection. You get faster alloy adjustment. Clean scrap input cuts down unwanted tramp elements from the start.

The real quality work happens after primary melting.

2. Digital Quality Systems: Ruling Out Human Error

Top German mills don’t rely on an operator’s “gut feeling.” They run unified digital platforms that capture data from the scrap yard to the loading dock. Every temperature curve, stirring duration, and vacuum level feeds into one central brain.

This does two things for you:

- Real-time Correction: If a furnace temperature drifts or vacuum time runs short, the system fires an alert instantly. Standardization happens during production, not just during final inspection.

- Predictive Blocking: Historical data models predict the final slab quality before it’s even cut. If the numbers suggest a risk of micro-defects, the system flags that heat for lower-grade use. It never reaches the high-end 1.2316 supply chain.

3. “Quality 4.0”: Algorithms vs. Opinions

Modern European mills have moved to cloud-based “Quality 4.0”. In the past, a quality manager might try to match a borderline batch to an order. Now, algorithms decide.

Automated assignment systems compare the finished steel’s chemistry and cleanliness against your exact order specs. If the data doesn’t fit the curve, the system blocks the shipment. No manual overrides. No “it’s close enough.” This removes the batch-to-batch variation caused by subjective human decisions.

4. Dynamic Composition Control Through Big Data

German mills use these models during production. Before tapping the heat, the system calculates micro-adjustments to alloying additions and refining steps. Composition hit rates reach near 100% within target windows. Exact percentages stay proprietary, but first-time acceptance rates beat industry averages by far.

For 1.2316, this means:

- Chromium lands in the 15.5–17.5% range without overshoot

- Molybdenum hits 0.8–1.3% every time

- Sulfur stays below 0.005% in ESR-processed batches, heat after heat

The system does more than control averages. It cuts standard deviation across batches. Your January order and your June order show almost identical microstructures.

Why This Matters for Your Mold Steel

Process stability shows up in working results. You machine 1.2316 blocks from different delivery lots. Tool wear patterns stay predictable. Polishing times stay stable. Heat treatment response stays uniform.

German mills export stability as much as steel. Their digital quality infrastructure cuts out the human variability that hurts less controlled operations. You pay a premium. But you’re buying reproducibility at industrial scale.

Strict Quality Management and Traceability

German mills track every heat from ladle to loading dock. Quality systems record data and enforce rules at each gate. A batch fails a checkpoint? It stops. No manual overrides. No shortcuts.

Strict Quality Gates: From Melt to Shipment

- Steelmaking Control: Each heat undergoes 2–3 chemical tests against limits tighter than DIN EN ISO 4957. Tapping temperature deviation is strictly held within ±10–15°C.

- Secondary Refining: Gas analysis ensures Oxygen ≤20–25 ppm and Hydrogen ≤2 ppm. All vacuum degassing and argon stirring parameters are digitally timestamped.

- Forging Standards: Critical 1.2316 blocks require a deformation ratio of ≥6 (vs. standard ≥3–4). Center segregation is capped at ≤1–2 grade.

- Heat Treatment Accuracy: Temperature control stays within ±5–10°C. Hardness variation across large sections is limited to just ≤2 HRC.

- Non-Destructive Testing (NDT): We execute 100% volumetric ultrasonic scanning to distinguish Grade 3 blocks from standard outputs. Nothing is assumed; every cubic inch is verified. Critical surfaces also undergo magnetic particle or penetration testing.

- Mechanical Verification: Every batch faces full longitudinal and transverse testing for tensile strength and impact toughness—no random spot checks allowed.

- Final Inspection: Dimensions follow EN 10060/10029 standards, with surface defect depth restricted to ≤1–2% of section thickness.

Full Traceability: Heat-to-Part Linkage

Every finished piece carries a heat number. That number unlocks the entire production history. Chemical composition tables. Gas analysis results. Forging ratios. Heat treatment curves. UT scan images. Mechanical test reports. Most German mills keep this data for 10+ years. You order 1.2316 in 2026. Five years later, you trace a tool failure back to the original melt record. That’s standard, not premium service.

R&D Capability and Customer Collaboration

German mills put 2–4% of revenue into R&D each year. High-end tool and mold steel operations hit the upper end of that range. Thyssen Krupp’s steel division keeps R&D spending near 2% of sales. Those funds go to high-performance grades. This includes corrosion-resistant mold steels like 1.2316.

1. Patent Portfolio in Corrosion-Resistant Mold Steel

German and European producers hold 30–40% of global patents for 1.2316 (X38CrMo16) and similar steels. These are corrosion-resistant plastic mold steels. Patent filings focus on three areas:

- Composition fine-tuning: Control of molybdenum, vanadium, nickel, and sulfur

- Secondary refining: ESR slag chemistry and vacuum degassing methods

- Heat treatment: Tempering steps for even hardness

Top German specialty steel mills—Böhler-Uddeholm, Deutsche Edelstahlwerke—file 20–80 patents each. These cover plastic and corrosion-resistant mold steels. Focus on “improved 1.2316 variants,” and counts drop to 5–20 per producer. These patents protect small gains. Tighter sulfur control. Better hardening throughout. Improved polish.

2. Joint Development Cycles with Mold Makers and OEMs

German mills don’t just sell steel. They build solutions with European mold manufacturers and automotive OEMs. Standard collaboration runs 12–36 months:

Month 1–6: Composition validation and lab testing

Month 7–18: Trial molds and small-batch injection tests

Month 19–36: OEM production qualification and volume ramp-up

Technical review meetings happen each month or quarter. Mold makers report polishing cycles. They note cracking and corrosion spots. Automotive projects follow M0/M1/M2/M3 milestones. Each gate needs material data. Plus mold life forecasts and trial run reports.

3. Performance Benchmarks in Customer Projects

Mills and customers set clear KPIs before joint development starts:

| Feature | Specification / Performance |

|---|---|

| Mold Life Improvement | 20–50% longer injection cycles versus baseline steels |

| Polish Finish |

|

| Corrosion Resistance |

|

| Hardness Uniformity |

|

4. Shared Data Packages

German producers give partners complete material data packages:including Chemical composition control ranges (tighter than DIN specs、Grain size ratings and cleanliness metrics (oxygen content, inclusion counts)、Transformation curves: S-curves, CCT/TTT diagrams for heat treatment planning andFailure analysis reports from past customer cases.

This openness builds trust. Mold makers get steel that behaves as expected. OEMs get quality chains they can trace. German mills win long-term contracts. They turn R&D into solutions built for each customer.

The Practical Purchasing Value and Selection Criteria

When the Premium Makes Sense

Choose German 1.2316 for:

✅Molds producing medical devices, optical parts, or cosmetic packaging—surface defects ruin entire production runs

✅Jobs where mirror polish is required, and rework costs more than the material premium

✅Projects needing corrosion resistance in humid or chemical environments without coatings

✅Multi-year production cycles where batch consistency beats first-cost savings

Skip the premium for:

❌Surface finish requirements above Ra 0.1 µm

❌Mold life under 100,000 cycles that meets your needs

❌Projects where cost-per-part drives decisions more than defect rates

German mills offer stability and repeatability at scale. You pay for their process control setup, not just the chemistry specs on paper.

Conclusion

Your production needs precision, consistency, and long-term reliability? Germany’s high-end 1.2316 market delivers. No marketing hype—just decades of proven metal expertise. German mills use vacuum degassing technology and isothermal annealing processes. They maintain full quality tracking systems. You get more stable quality because these mills compete on engineering excellence, not price.