Understanding ESR in 1.2316: The Hidden Standard for Optical Molds

In the world of precision mold making, particularly for optical lenses and medical devices, the stake is high. You aren’t just buying a block of steel; you are paying for the final surface finish.

Here is the reality many procurement managers face: You order standard 1.2316 tool steel expecting a mirror finish. The machining goes well. But weeks later, during the final polishing stage, the technician reports a problem. “Orange peel” textures that won’t buff out. Tiny pinholes appearing out of nowhere just as the surface hits #8000 grit. Suddenly, a mold worth tens of thousands of dollars is at risk of being scrapped—not because of bad workmanship, but because of the steel’s internal DNA.

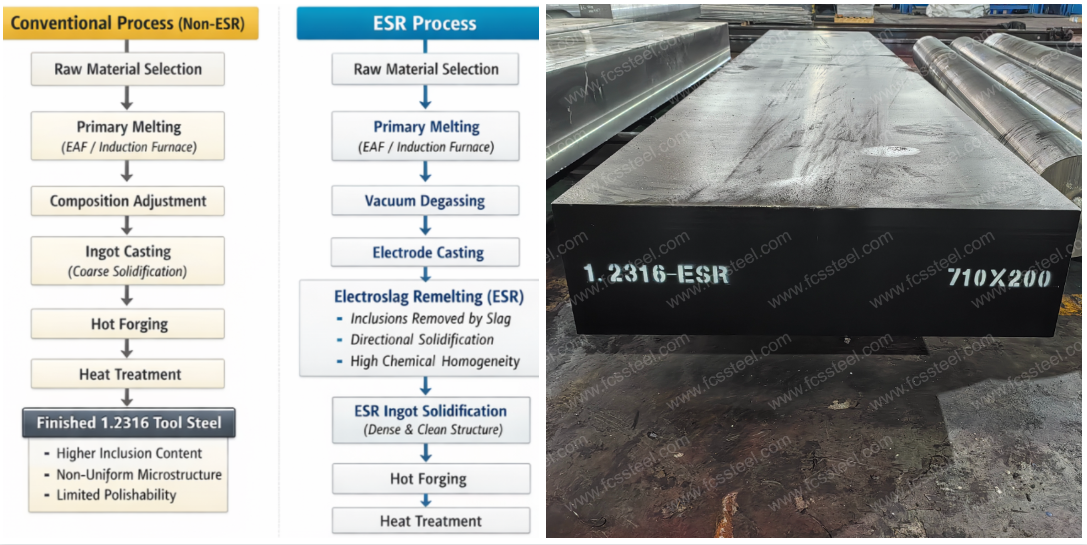

This is where the Electro-Slag Remelting (ESR) process draws the line between “good enough” and “flawless.”

While standard 1.2316 offers decent corrosion resistance, ESR-refined material is engineered structurally to eliminate the microscopic defects that ruin high-gloss finishes. It transforms the steel from a standard commodity into a pure, homogenous material capable of optical clarity.

In this guide, we won’t just tell you that ESR is “better.” We will show you exactly how it alters the microstructure to cut your polishing time by 40%, extend tool life, and—most importantly—how to verify you are actually getting the ESR quality you paid for, rather than just a stamped certificate.

1. The Microscopic Difference: Cleanliness & Polishability

When it comes to mirror polishing, it’s often what you can’t see that causes the biggest headaches. Standard 1.2316 might look solid, but deep inside, it often hides non-metallic inclusions reaching up to 50 μm in diameter. To a polisher, these aren’t just microscopic specs—they are “landmines.”

During the final buffing stages, these brittle oxide clusters tend to break out, leaving behind visible pits (pinholes) just as you reach a high-gloss finish. This forces expensive rework or, in worst-case scenarios, scars that cannot be polished out without losing dimensional tolerance.

How ESR Eliminates the “Pitting” Risk

The Electro-Slag Remelting process acts as a rigorous filter, chemically absorbing these impurities into the slag pool. The result is a dramatic shift in internal hygiene:

- Average inclusion size drops to ~10 μm (a 50% reduction).

- Maximum defect size is capped at ~28 μm, removing the large clusters that cause visible surface flaws.

This leap in cleanliness is why ESR material is mandatory for #10000 grit (Ra < 0.05 μm) optical finishes. You aren’t just paying for “cleaner” steel; you are buying a noticeable reduction in labor. Polishing technicians report saving 40% or more on bench time simply because they stop fighting against the material’s internal defects. For medical device housings or high-end cosmetic packaging, this reliability is the difference between a profitable run and a scrapped mold.

2. Hardness Uniformity: The End of “Orange Peel” and Warpage

One of the most frustrating issues in mold making is the “orange peel” effect—that uneven, wavy texture that appears just as you are trying to reach a perfect mirror finish. While often blamed on poor polishing technique, the real culprit is usually the steel itself.

Standard 1.2316 is prone to segregation. It contains soft zones (delta ferrite) and hard zones (carbide clusters) side by side. When you polish, the soft areas erode faster than the hard ones, creating an undulating surface.

How ESR Solves the Consistency Problem

ESR (Electro-Slag Remelting) acts as a structural equalizer. The rapid, controlled cooling rate prevents carbides from clumping together, forcing them to distribute evenly across the matrix. This results in consistent hardness—typically 280-325 HB (approx. 30-34 HRC)—that holds true from the surface skin right down to the core of the block.

This uniformity delivers two critical advantages:

- Flawless Mirror Perception: With no soft spots to drag out and no hard spots to resist the buffing wheel, the material responds evenly to abrasives. You get a true, flat reflection without the wavy distortion of orange peel, even on large surface areas (e.g., 500mm+ wide plates).

- Dimensional Stability: Internal stress is often caused by irregular cooling structures. Because ESR material is homogenous, it exhibits predictable thermal expansion. You can machine complex, deep cavities with < 0.01 mm tolerance holding capability, and you eliminate the risk of the steel warping after heavy machining operations.

For large-format molds, such as automotive lens creates or wide LCD backing plates, this cross-sectional consistency is the only way to ensure the center of the mold polishes as brilliantly as the corners.

3. Mechanical Property Improvements

ESR material delivers measurable toughness gains compared to vacuum-degassed 1.2316:

| Property | Standard (VD) | ESR Improvement |

|---|---|---|

| Ductility | Baseline | +10% |

| Contraction | Baseline | +18% |

| Notched Toughness (20°C) | Baseline | +46% |

| Notched Toughness (-40°C) | Baseline | +30% |

The toughness boost matters for molds that go through thermal cycling. ESR-refined 1.2316 resists crack formation better. This happens during repeated heating and cooling cycles in production environments.

4. Corrosion Resistance: Why Chemistry & Purity Must Work Together

You choose 1.2316 primarily for its ability to survive in harsh environments. Its performance relies on a specific chemical baseline: ~16% Chromium to create a passive oxide barrier, and ~1.1% Molybdenum to resist pitting from chlorides.

However, chemistry alone isn’t enough. Standard melted steel often contains sulfide and oxide inclusions that break this protective layer. Think of these inclusions as “punctures” in a raincoat—it doesn’t matter how waterproof the fabric is if there are holes in it.

How ESR Amplifies Corrosion Defense

This is where ESR refining changes the game. By remelting the steel through a reactive slag, it strips out the sulfur and non-metallic particles that act as corrosion initiation sites.

The result is a continuous, unbroken passivation layer that offers superior protection against:

- PVC Outgassing: During processing, PVC releases hydrochloric acid (HCl) vapor. The Molybdenum content neutralizes these acids, while the clean ESR structure prevents distinct “attack zones” where pits usually form.

- Humid Storage Conditions: In tropical climates or during weekend shutdowns, stagnant cooling water can wreck a mold. The uniform chromium distribution in ESR blocks ensures the steel resists flash rust far longer than standard grades (which often suffer from “chromimum-depleted” spots due to segregation).

In salt-spray testing, ESR 1.2316 consistently achieves Corrosion Class 2-3 (on a 0-5 scale, where lower is better), significantly outperforming standard vacuum-degassed versions which typically fail earlier due to internal impurities.

5. Critical Applications Where ESR 1.2316 Beats Standard Grade

Medical device housings, PVC injection molds, and high-gloss consumer electronics all need the same thing: zero tolerance for surface defects. ESR 1.2316 tool steel delivers what standard grades can’t in these tough production settings.

1. Medical and Food-Grade Molds

Hospital-grade cleaners attack mold surfaces every production cycle. Standard 1.2316 develops tiny pits after exposure to quaternary ammonium compounds and chlorine cleaners. The surface breaks down. Sites form where bacteria can hide.ESR-refined material handles 10,000+ cleaning cycles without surface breakdown.

2. PVC Processing

PVC breaks down from heat and releases hydrochloric acid vapor inside the mold cavity. Standard 1.2083 develops visible pits within 50,000 cycles. The 12-14% chromium content can’t handle sustained HCl exposure. Surface roughness grows. Cavity size shifts out of spec.

ESR 1.2316’s molybdenum addition (0.8-1.3%) blocks acidic gas damage. The even carbide spread prevents attack zones. Window profile molds and cable insulation tooling run 200,000+ cycles without re-polishing.

Glass fiber-reinforced PVC compounds add wear to chemical attack. ESR material’s even 280-325 HB hardness fights both at once. Mirror-finish cavities stay clear through the entire tool life.

3. High-Humidity Production Floors and Water-Based Cooling Systems

Tropical plants destroy standard 1.2083 molds. Weekend shutdowns create the perfect corrosion mix: stagnant cooling water + 85% humidity. Monday morning brings rust blooms across cavity surfaces. Production delays start before the first shot.

ESR 1.2316’s 16% average chromium forms a thicker protective oxide layer. Water-based coolant sits in drilled channels for 60+ hours without rust. The steel fights flash rust that standard grades develop in 48 hours. Caribbean and Southeast Asian plants run ESR tooling all year without corrosion shutdowns.

Clogged cooling channels cut heat transfer. Standard materials rust from the inside. Rust bits block flow passages. ESR 1.2316 keeps waterways clean. Cycle times stay the same. Temperature control holds steady through multi-year production runs.

6. ESR Specification and Quality Verification: Don’t Get Scammed

Real ESR 1.2316 follows the EAF+LF+VD+ESR four-stage process. Skip any step? You’re not getting genuine electro-slag refined material. You’re just paying premium prices for standard grade.

Process Stage & Verification Points

| Stage | Acronym | Primary Function | Key Quality Parameters | Verification on Mill Certificate |

|---|---|---|---|---|

| 1. Initial Melting | EAF | Sets the base alloy chemistry. | C: 0.33-0.43% Cr: 15.0-17.0% Mo: 1.00-1.30% |

Must list chemistry within these ranges. |

| 2. Refining | LF | Homogenizes composition & temperature; initial inclusion control. | Composition uniformity across the heat. | Process step should be listed. |

| 3. Degassing | VD | Removes gases (H, N, O); increases purity. | Lower gas content levels. | Process step should be listed. Note: Does not fix segregation. |

| 4. Critical Remelting | ESR | Eliminates segregation; creates uniform microstructure. | Defect size ≤ Class 4 (GB/T 6402-2008). Uniform carbide distribution. |

THE CRITICAL STEP. Full sequence EAF+LF+VD+ESR must be stated. |

⚠️ Critical Procurement Warning

A common non-conformance is suppliers substituting the full ESR process with only the first three steps (EAF+LF+VD) while charging for premium ESR-grade material.

Your technical specification must explicitly state:

“Material shall be produced via the full sequence: EAF → LF → VD → ESR.”

Verification of the complete chain on the mill certificate is the primary defense against receiving inferior, non-ESR material. The ESR step is what defines the enhanced microstructure, uniformity, and defect control of the premium grade.

Mandatory Quality Certificates to Demand

Don’t accept generic mill certificates. Request these specific documents:

1. Material Certificate (EN 4957-2000 compliance)

Chemical composition breakdown showing actual percentages—not just “within range.” Verify carbon 0.33-0.43%, chromium 15-17%, molybdenum 1-1.3%. ESR process confirmation stamped on the cert.

2. Ultrasonic Testing Report (GB/T 6402-2008 Class 4)

Defect classification by size:

– Class A: Fine defects max 1.0 mm / Coarse max 0.5 mm

– Class B: Fine 1.5 mm / Coarse 1.0 mm

– Class C: Fine 1.0 mm / Coarse 1.0 mm

– Class D: Fine 1.5 mm / Coarse 1.0 mm

Genuine ESR material shows mostly Class A results. Standard refining shows larger Class B-D defects scattered throughout.

3. Metallographic Analysis

Carbide distribution patterns. Residual austenite content. Microstructure photos showing martensite morphology post-heat treatment. ESR structure looks uniform under magnification. No banding patterns. No centerline segregation zones.

4. Hardness Test Data

Pre-hardened delivery should show 28-32 HRC (280-325 HB equivalent). Test points must include center, mid-radius, and edge positions. ESR material varies ±1 HRC maximum across the cross-section. Standard grades show ±2-3 HRC swings.

Actionable Procurement Checklist

Before signing purchase orders:

- Demand ESR-specific production logs showing slag composition and remelt parameters

- Require third-party UT and metallographic verification—not just supplier internal testing

- Reject certificates listing “EAF/ESR” without the critical LF and VD intermediate steps

- Request sample blocks for independent hardness and polishability testing before bulk orders

- Verify the supplier’s ESR furnace capacity matches your order volume—subcontracting often means quality loss

Genuine ESR 1.2316 costs 15-25% more than standard vacuum-degassed material. That premium disappears fast. You cut polishing time by 40%. You extend tool life through 200,000+ cycles without cavity replacement.

Conclusion

ESR 1.2316 tool steel makes the difference between good performance and great results in precision molding. Your project needs optical-grade cleanliness? You want consistent hardness from core to surface? Or you’re after that mirror finish without endless polishing? ESR processing turns 1.2316 from a solid performer into a top champion.

The numbers are clear: Standard 1.2316 works fine for general-purpose molds. But ESR is a must for optical lenses, medical-grade parts, cosmetic packaging, and any job where surface defects mean rejected products or long downtime. ESR cuts down non-metallic inclusions. This alone slashes polishing time by 40-60%. Plus, you get better corrosion resistance in acidic injection molding environments.

Your mold’s performance limit gets set the moment you pick your steel grade. Make the right choice.