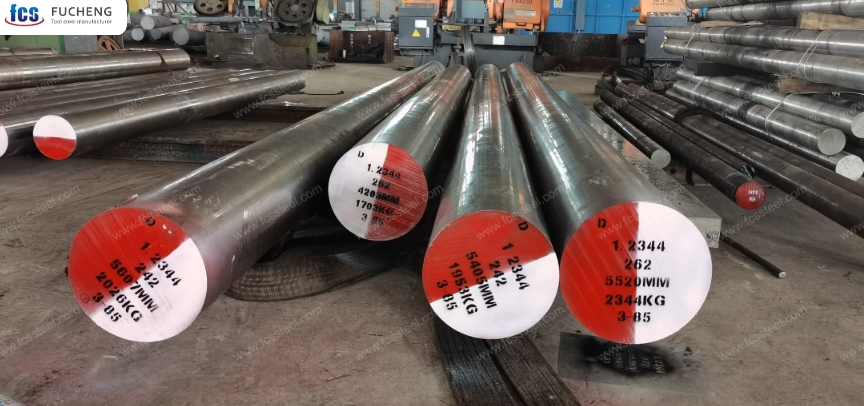

In aerospace manufacturing, materials selection is a critical decision that directly impacts safety, efficiency, and cost performance. Among the many alloys available for tool and die applications, 1.2344 tool steel—also known as X40CrMoV5-1 under the German DIN standard and equivalent to H13 in ASTM standards—stands out as a proven choice for hot forging dies.

French aerospace suppliers, who serve globally recognized companies such as Airbus, Dassault Aviation, and Safran, rely heavily on 1.2344 steel to meet demanding performance standards. This article explores the seven main reasons why this material remains the preferred solution, highlighting the connection between aerospace-specific requirements, heat fatigue resistance, and dimensional stability.

1. Superior Resistance to Thermal Fatigue

Hot forging dies in aerospace production are subjected to extreme thermal cycling—dies must withstand rapid heating when in contact with red-hot titanium, nickel alloys, or stainless steels, followed by fast cooling during lubrication and removal processes.

-

1.2344 steel contains chromium, molybdenum, and vanadium, elements that form stable carbides, giving the alloy exceptional resistance to heat checking and cracking.

-

In laboratory testing, 1.2344 consistently demonstrates better resistance to thermal fatigue cracking than conventional cold work steels.

-

French aerospace forging shops report that using 1.2344 dies can extend tooling life cycles by up to 20–30% compared to standard hot work steels, reducing downtime and tooling replacement costs.

This resilience against thermal stress is crucial for aerospace suppliers who must maintain tight schedules and uninterrupted production cycles.

2. Dimensional Stability Under Repeated Stress

Precision is the cornerstone of aerospace. Components such as turbine disks, landing gear parts, and structural fittings require micron-level accuracy in their forged geometry.

-

During forging, tools expand and contract under high temperature and pressure. A material that lacks dimensional stability can distort, leading to out-of-tolerance parts.

-

1.2344 offers excellent resistance to deformation under cyclic thermal loading, maintaining its geometry even after hundreds of forging cycles.

Studies from European aerospace research groups show that 1.2344’s coefficient of thermal expansion (around 11.2 µm/m·K at 20–100 °C) is well-balanced, reducing risks of distortion when compared to alternative alloys.

This property helps French aerospace suppliers maintain first-pass yield rates above 95%, a benchmark that keeps scrap costs low and production schedules efficient.

3. High Toughness and Impact Resistance

Unlike automotive or consumer product forging, aerospace forging involves difficult-to-deform alloys such as titanium (Ti-6Al-4V) and nickel-based superalloys (Inconel series). These materials exert immense forces on dies, increasing the risk of cracking or catastrophic failure.

-

1.2344 steel retains high toughness even at elevated temperatures (up to 600 °C).

-

Its balanced composition prevents brittleness while maintaining strength, ensuring that dies do not crack under repeated heavy loads.

For aerospace suppliers, this translates into reliable operation during the forging of high-value parts, where even a single tool failure can cost tens of thousands of euros in wasted material and downtime.

4. Compatibility with Surface Treatments and Nitriding

To extend die life, many aerospace suppliers use surface treatments such as nitriding or PVD coatings. These methods improve wear resistance and further protect against heat checking.

-

1.2344 is particularly well-suited to gas nitriding and plasma nitriding, as its alloy content supports the formation of a hard, wear-resistant diffusion layer without excessive distortion.

-

Nitrided 1.2344 forging dies show a 30–50% increase in service life, according to European forging industry reports.

This adaptability makes the material a cost-effective long-term investment, as suppliers can optimize performance through tailored heat treatments.

5. Proven Track Record in Aerospace Forging

A key reason French aerospace suppliers continue to rely on 1.2344 is its longstanding proven record in both Europe and the United States.

-

The H13 equivalent has been used for decades in the aerospace industry for forging dies, extrusion tools, and die casting molds.

-

In France, industry certifications such as NADCAP (National Aerospace and Defense Contractors Accreditation Program) recognize 1.2344-based dies as compliant with aerospace forging quality standards.

This long history of reliable performance means that aerospace OEMs and Tier-1 suppliers trust the material for safety-critical components, reducing the risks associated with experimenting with unproven alternatives.

6. Cost-to-Performance Efficiency

While there are more advanced hot work steels and even powder metallurgy (PM) steels available, 1.2344 strikes a balance between cost and performance.

-

Alternative PM steels like Uddeholm Dievar or Böhler W360 may offer slightly higher thermal fatigue resistance but are significantly more expensive.

-

For large dies used in forging aerospace components, material cost is a major factor. Choosing 1.2344 allows suppliers to achieve reliable performance at a lower cost-per-cycle.

For French aerospace companies, which face tight budgetary controls while competing globally, 1.2344 offers a strategic economic advantage.

7. Availability and Global Standardization

Finally, one of the most practical reasons for 1.2344’s dominance in French aerospace forging is its wide availability and global standardization.

-

1.2344 is standardized under DIN, EN, and ASTM, making it interchangeable with H13 in international supply chains.

-

Major steel suppliers in Europe, Asia, and North America maintain consistent quality certifications (ISO 4957, ASTM A681), ensuring dependable supply for aerospace toolmakers.

This availability reduces risks of supply chain delays, which is vital for French aerospace suppliers who must align with strict delivery schedules for Airbus and other OEM programs.

Substitution Considerations: When Alternatives May Be Preferred

Although 1.2344 is the primary choice, aerospace engineers sometimes consider alternatives based on specific production challenges:

-

Dievar (Uddeholm) or W360 (Böhler): Superior thermal fatigue resistance for very high-cycle forging of nickel superalloys, though at a higher cost.

-

1.2367 (X38CrMoV5-3): Better toughness at higher temperatures, suitable for large dies with extreme service demands.

-

Powder Metallurgy Hot Work Steels: Offer uniform microstructure and longer tool life but are less cost-efficient for large-scale applications.

These alternatives demonstrate that while 1.2344 is widely trusted, aerospace forging suppliers continuously evaluate material strategies to match evolving demands.

Conclusion

French aerospace suppliers rely on 1.2344 steel for hot forging dies because it delivers the right balance of thermal fatigue resistance, dimensional stability, toughness, adaptability, cost-efficiency, and global availability.

Its track record in aerospace forging ensures reliable performance when manufacturing high-value, safety-critical parts, and while advanced alloys exist, 1.2344 remains the practical standard for most forging applications in the French aerospace sector.

By combining proven performance with adaptability to treatments like nitriding, 1.2344 continues to support the aerospace industry’s drive toward safety, precision, and efficiency in hot forging.