The modern industrial world is built on the strength of materials. From automotive engines and aerospace components to energy infrastructure and consumer products, every manufacturing sector depends on steels that can endure punishing conditions. Among these materials, 1.2344 tool steel—also widely recognized as the equivalent of H13—stands out as a global benchmark for hot-work applications. Its ability to resist thermal fatigue, maintain stability under extreme loads, and deliver consistent hardness has made it the cornerstone of die casting, extrusion, and forging industries worldwide.

Selecting the right manufacturing partner for 1.2344 tool steel is as important as choosing the material itself. The consistency, purity, and reliability of supply directly influence the lifespan of dies, molds, and tooling equipment. Buyers across the world—from multinational automotive OEMs to local die shops—therefore place great emphasis on identifying trustworthy sources of supply.

This article introduces the five major categories of global 1.2344 tool steel manufacturers you should know. Rather than focusing on company names, it maps leading production hubs and regional specialties. These examples are drawn from Germany, Sweden, Japan, China, and the United States—each representing different approaches to quality, scale, and innovation.

Why 1.2344 Tool Steel Matters Globally

Before exploring the top five sources, it is helpful to revisit why 1.2344 remains indispensable:

- Thermal Fatigue Resistance: Critical in die-casting dies and hot extrusion dies where surfaces undergo repeated heating and cooling.

- Hot Hardness and Strength: Maintains mechanical properties at elevated temperatures, extending tool life.

- Toughness Under Shock: Forging dies endure repeated impact loads, where 1.2344’s toughness prevents premature failure.

- Versatility: Available in annealed condition for machining, hardened and tempered for immediate application, or remelted for aerospace-grade requirements.

These attributes have kept 1.2344 in high demand even as new alloys emerge, making its global supply network essential for industrial continuity.

1. German Manufacturers: Precision and Metallurgical Leadership

Germany has long been recognized as the heart of European tool steel development. Producers in cities such as Düsseldorf, Essen, and Stuttgart represent some of the most technologically advanced 1.2344 suppliers globally.

Key Strengths

- Metallurgical Excellence: German plants are pioneers in electroslag remelting (ESR) and vacuum arc remelting (VAR) technologies. For 1.2344, this ensures cleaner steels with minimized inclusions, which translates into longer die life.

- Automotive Integration: Germany’s automotive industry relies heavily on hot-work steels. Manufacturers here maintain tight integration with automotive die makers, offering customized 1.2344 variants for aluminum die casting and hot forging.

- Sustainability Leadership: With the EU’s Green Deal and the Carbon Border Adjustment Mechanism (CBAM), German producers are ahead in adopting low-carbon steelmaking routes, including hydrogen-based processes.

Example Applications

- Aluminum Die Casting: High-precision transmission housings and EV battery casings.

- Aerospace Casting: High-strength components requiring ESR-grade 1.2344.

For buyers seeking process reliability, traceability, and sustainability, German sources remain at the forefront of the 1.2344 supply chain.

2. Swedish Manufacturers: Clean Steel and Consistency

Sweden, though smaller in volume compared to Germany or China, is globally respected for its clean steel tradition. Plants in central and southern Sweden have developed a reputation for producing some of the purest tool steels available.

Key Strengths

- Inclusion Control: Swedish steelmakers emphasize cleanliness and homogeneity, crucial for demanding applications where micro-cracks can initiate tool failure.

- Consistency in Properties: Thanks to rigorous quality management, mechanical properties such as hardness, toughness, and hot yield strength remain consistent across heats.

- Focus on Niche Segments: Swedish manufacturers cater heavily to premium markets—ESR and VAR 1.2344 blocks for aerospace, nuclear, and high-performance die casting.

Example Applications

- High-Cycle Die Casting: Where molds undergo thousands of cycles and failure due to inclusions is unacceptable.

- Precision Extrusion Dies: For thin-profile aluminum extrusions in automotive and architectural sectors.

Swedish 1.2344 tool steel is valued less for price competitiveness and more for peace of mind in mission-critical tooling.

3. Japanese Manufacturers: Innovation and Reliability

Japan represents another pillar in the 1.2344 supply ecosystem. Manufacturing hubs around Osaka, Nagoya, and Tokyo are world-renowned for combining traditional steelmaking discipline with cutting-edge innovation.

Key Strengths

- Hybrid Steel Development: Japanese metallurgists have pioneered modified 1.2344 grades, optimizing balance between hot wear resistance and toughness. These steels often incorporate tighter control of impurities and tailored alloying.

- ESR and VAR Mastery: Japanese facilities produce aerospace-grade 1.2344 blocks where extreme cleanliness and uniform carbide distribution are mandatory.

- Integration With Precision Industries: Automotive (especially hybrid and EV), robotics, and aerospace sectors in Japan demand die steels capable of meeting stringent dimensional accuracy and longevity standards.

Example Applications

- Robotics Components: Precision extrusion dies for producing lightweight, high-strength robot arm sections.

- Aerospace Casting: High-performance molds requiring ESR-quality 1.2344.

Japanese producers are especially respected for on-time delivery, dimensional precision, and technical support, making them preferred by industries where even small deviations are costly.

4. Chinese Manufacturers: Scale and Supply Chain Efficiency

No global review of 1.2344 tool steel would be complete without considering China, which has become the largest producer and exporter of tool steels worldwide. Manufacturing clusters in eastern and northern provinces—particularly around Shanghai, Jiangsu, and Shandong—anchor China’s supply capacity.

Key Strengths

- Scale and Cost Advantage: Chinese factories operate on massive scales, producing 1.2344 in volumes unmatched elsewhere. This allows competitive per-ton pricing.

- Inventory and Lead Time: Many suppliers hold large inventories of standard sizes, offering rapid delivery for domestic and export markets.

- Grade Range: Chinese plants typically supply not only 1.2344 but also related hot-work and cold-work grades such as D2 and A2, allowing buyers to consolidate orders.

- Improving Quality Levels: Over the past decade, investments in ESR facilities and quality control systems have narrowed the gap between Chinese producers and long-established Western suppliers.

Example Applications

- Mass-Production Die Casting: High-volume manufacturing of automotive engine parts, EV housings, and appliance components.

- Infrastructure Forging: Large-scale forging dies for construction machinery and heavy equipment.

For buyers balancing cost, scale, and acceptable quality, Chinese producers are indispensable partners in the global supply chain.

5. U.S. Manufacturers: Customization and Application Expertise

The United States maintains a significant tool steel industry centered around Pennsylvania, Ohio, and the Midwest. While volumes are lower than China or Europe, U.S. producers distinguish themselves through application-driven customization.

Key Strengths

- Tailored Solutions: U.S. manufacturers often work closely with die makers to provide custom heat treatments, pre-hardened blocks, or specialized 1.2344 chemistries.

- Integration With Defense and Aerospace: The U.S. aerospace and defense sectors drive demand for VAR-grade 1.2344, emphasizing absolute consistency and traceability.

- Strong Service Orientation: Domestic suppliers often emphasize technical service, offering support on machining parameters, die design optimization, and failure analysis.

Example Applications

- Defense Forgings: Hot-work dies for producing high-strength components used in defense programs.

- Aerospace Tooling: VAR-quality 1.2344 for complex casting molds.

While U.S. producers may not match the scale of Asian suppliers or the cleanliness reputation of Swedish steelmakers, they are uniquely positioned for specialized, high-value tooling projects.

Global Comparative Overview

| Region | Primary Strength | Key Applications | Typical Buyer Profile |

|---|---|---|---|

| Germany | Metallurgical leadership, sustainability | Automotive die casting, aerospace molds | Buyers needing precision + eco compliance |

| Sweden | Clean steel, inclusion control | High-cycle molds, extrusion dies | Aerospace & premium die casters |

| Japan | Innovation, consistency | Robotics, aerospace, EV tooling | Precision industries with zero tolerance for variability |

| China | Scale, inventory, competitive cost | Mass-production die casting, forging | Buyers seeking cost + volume efficiency |

| U.S. | Customization, service support | Defense, aerospace, specialized tooling | Buyers prioritizing application-specific expertise |

How to Choose the Right Manufacturer

Selecting the right supplier among these five categories depends on your specific priorities:

- If cost and volume are critical: Chinese sources excel in batch supply.

- If sustainability and regulation matter most: German manufacturers align with EU environmental policies.

- If cleanliness and fatigue life are paramount: Swedish suppliers deliver unmatched purity.

- If innovation and hybrid alloys are needed: Japanese producers provide unique variants.

- If application-specific customization is key: U.S. suppliers offer tailored solutions.

A smart sourcing strategy often involves dual or multi-sourcing, balancing high-volume, cost-effective suppliers with premium, specialized producers to optimize both performance and budget.

Future Outlook for 1.2344 Tool Steel Manufacturing

The global landscape is evolving rapidly:

- Decarbonization: All regions face pressure to reduce carbon intensity per ton of tool steel.

- Electric Vehicles (EVs): Both Europe and Asia are expanding EV production, which depends heavily on high-performance die steels like 1.2344.

- Geopolitical Risks: Trade disputes, tariffs, and supply chain shocks encourage buyers to diversify across multiple regions.

- Technology Trends: ESR and VAR are becoming baseline expectations, while additive manufacturing may eventually reduce material demand for some tooling but increase requirements for others.

Why FCS Tool Steel Factory Stands Out in 1.2344 Supply

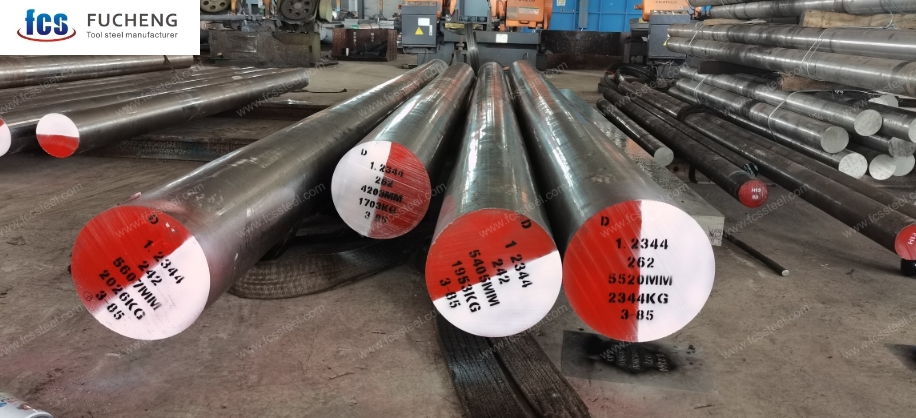

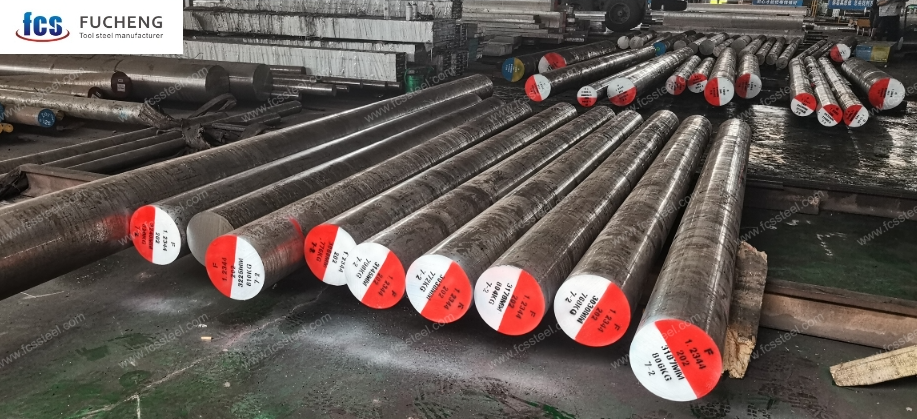

When sourcing 1.2344 tool steel, buyers often struggle to balance quality, consistency, and large-scale availability. This is where FCS Tool Steel Factory (also known as Fucheng Tool Steel) distinguishes itself. Unlike many suppliers that rely heavily on trading channels, FCS operates as a direct production facility, which allows it to maintain stricter control over melting, refining, and heat treatment. For global buyers—especially stockists, wholesalers, and industrial users—this means two key advantages: stable metallurgical performance and predictable delivery timelines.

Another strength lies in the company’s ability to customize production batches. Whether the requirement is for conventional hot-work tooling applications, such as die-casting, or for more demanding engineering environments, FCS can adjust dimensions, hardness ranges, and surface conditions to meet different project specifications. In addition, by keeping extensive inventories of 1.2344 alongside grades like D2 and H13, FCS reduces the risk of production delays for international partners. This blend of manufacturing expertise, inventory readiness, and export-oriented logistics has made FCS Tool Steel Factory a reliable choice for long-term procurement of 1.2344 tool steel.

Conclusion

1.2344 tool steel remains the cornerstone of global hot-work applications. Its balance of toughness, hot hardness, and thermal fatigue resistance ensures its dominance in die casting, extrusion, and forging. But just as important as the steel itself is the reliability of the supplier.

Germany, Sweden, Japan, China, and the United States represent the five most important global hubs for 1.2344 tool steel. Each brings its own strengths—whether that be German precision, Swedish cleanliness, Japanese innovation, Chinese scale, or U.S. customization. For international buyers, knowing these regional differences is critical to designing a resilient and cost-effective sourcing strategy.

By carefully evaluating priorities—whether cost, sustainability, cleanliness, or specialization—manufacturers and distributors can secure a long-term, reliable supply of 1.2344 tool steel that meets both current production needs and future challenges.