Germany’s automotive industry is renowned for its precision engineering and high-volume production of lightweight aluminum components. At the heart of this process are high-pressure die casting (HPDC) plants, which supply parts ranging from engine blocks and transmission housings to structural battery enclosures for electric vehicles.

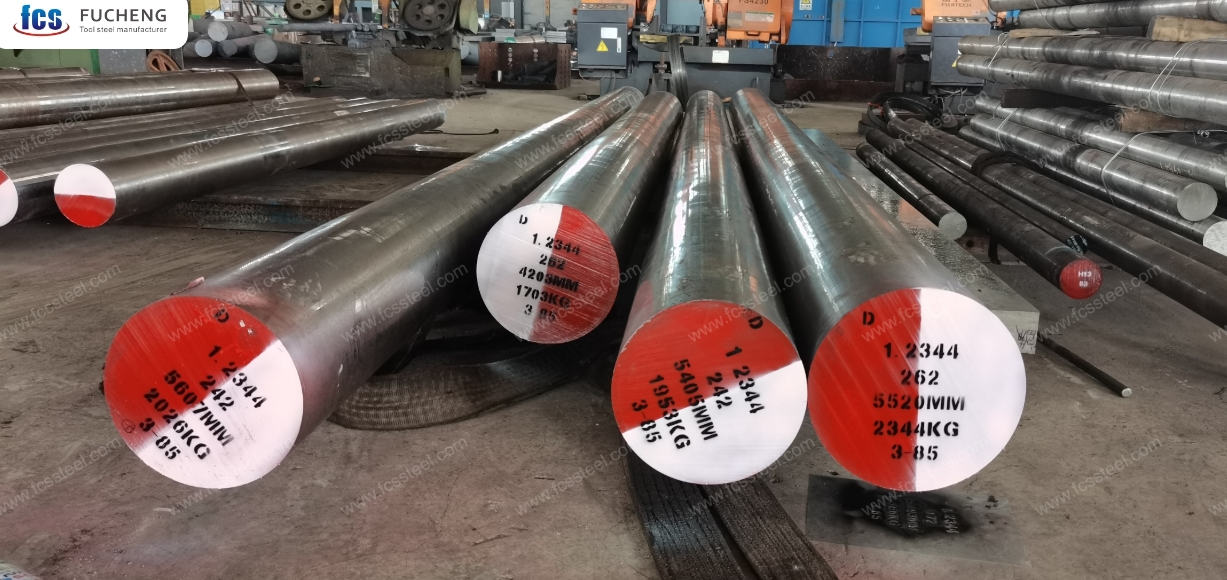

The dies used in HPDC are exposed to extreme thermal and mechanical stresses. Their longevity and performance depend heavily on the choice of tool steel. Among the available grades, 1.2344 steel (X40CrMoV5-1, equivalent to H13 in ASTM standards) has emerged as a proven and trusted material for German die casting plants.

To help technical buyers, tooling engineers, and quality managers make informed decisions, this article outlines the 12 key performance indicators (KPIs) that define why 1.2344 steel is so effective in HPDC applications.

1. Resistance to Thermal Fatigue

One of the leading failure modes in HPDC dies is heat checking—fine cracks caused by rapid heating and cooling cycles.

- 1.2344 steel, with its chromium, molybdenum, and vanadium alloying, resists crack initiation.

- In comparative studies, dies made of 1.2344 show 20–30% longer service life before heat checking compared to less alloyed hot work steels.

For German die casting plants running 24/7 production cycles, this translates to fewer die replacements and reduced downtime.

2. Hot Hardness Retention

During casting, dies face contact temperatures up to 600 °C. A material must maintain hardness at elevated temperatures to resist plastic deformation.

- 1.2344 maintains hardness above 44 HRC even at service temperatures.

- This ensures consistent die geometry, critical for maintaining tight tolerances in automotive castings.

3. Thermal Conductivity

Efficient heat transfer reduces hot spots, minimizing thermal gradients that can cause cracks.

- 1.2344 has a thermal conductivity of approximately 28–30 W/m·K at 500 °C.

- While lower than pure copper alloys, it provides a balanced compromise between conductivity and strength, especially when combined with optimized cooling channel designs.

For Germany’s die casting plants producing thin-walled structural parts, this balance is essential for uniform solidification and dimensional stability.

4. Toughness and Impact Resistance

High injection pressures—often above 100 MPa in HPDC—create intense mechanical loading.

- 1.2344 offers superior Charpy V-notch impact strength (20–25 J at room temperature) compared to standard hot work steels.

- This toughness reduces the risk of catastrophic die failure during sudden pressure spikes.

5. Hardenability

Large dies for automotive components require through-hardening to maintain performance across thick sections.

- 1.2344 exhibits excellent hardenability, allowing uniform hardness up to 150–200 mm cross-section thickness.

- This ensures that even massive dies used in Germany’s high-tonnage HPDC machines achieve consistent mechanical properties.

6. Wear Resistance

Repeated metal flow erodes die surfaces, particularly at gating and runner areas.

- Vanadium carbides in 1.2344 contribute to high wear resistance.

- Studies show that nitrided 1.2344 dies exhibit up to 50% longer service life in erosive zones.

This property reduces maintenance costs for German plants producing millions of components annually.

7. Resistance to Hot Cracking

Hot cracking occurs when high thermal stresses cause sudden fracture during production.

1.2344 resists hot cracking due to its balanced alloy content and microstructure stability.

In field performance, German HPDC suppliers report significantly fewer early die failures with 1.2344 compared to lower-grade steels.

8. Surface Treatment Compatibility

Die life can be extended through nitriding, PVD coatings, or laser hardening.

- 1.2344 responds well to nitriding, forming a hard diffusion layer of 800–1,200 HV with minimal dimensional distortion.

- It is widely compatible with CrN or AlTiN PVD coatings, enhancing wear and oxidation resistance.

This flexibility allows German die casting engineers to tailor surface properties for specific aluminum alloys.

9. Machinability and Toolmaking Efficiency

Tool steels must not only perform in service but also be manufacturable.

- In the annealed condition, 1.2344 offers good machinability (~75% relative to free-cutting steel).

- This reduces toolmaking lead time, a critical KPI for Germany’s automotive sector, where rapid die replacement schedules are common.

10. Dimensional Stability During Heat Treatment

Die precision depends on minimal distortion during hardening.

- 1.2344 shows low dimensional change (<0.03%) when properly heat-treated.

- This stability minimizes costly post-hardening machining, a major advantage for large and complex HPDC dies.

11. Oxidation and Scaling Resistance

At elevated die temperatures, oxidation can roughen surfaces and impair part release.

- Chromium in 1.2344 provides good resistance to scaling up to 600 °C.

- This helps maintain smooth die surfaces, ensuring consistent casting quality.

12. Cost-to-Performance Ratio

Finally, one of the most practical KPIs is the balance between performance and cost.

- While advanced PM steels or copper-based composites may offer higher conductivity or fatigue resistance, they are significantly more expensive.

- 1.2344 provides a well-balanced cost-to-life ratio, making it the standard choice for German HPDC plants.

According to industry estimates, dies made from 1.2344 reduce total tooling costs by 15–25% over the life cycle compared to alternatives.

Conclusion

For Germany’s high-pressure die casting industry—supplying critical components to automotive and aerospace sectors—the choice of die material is directly linked to efficiency, product quality, and sustainability.

The 12 performance indicators outlined above demonstrate why 1.2344 steel remains the benchmark for HPDC tooling:

- It withstands thermal fatigue, hot cracking, and wear,

- Maintains dimensional stability under demanding heat treatment,

- Is fully compatible with modern surface engineering,

- And achieves the best cost-to-performance ratio for high-volume production.

As German HPDC plants continue to support the shift to electric mobility and lightweight engineering, 1.2344 tool steel will remain a critical enabler of performance and competitiveness.