Germany’s manufacturing sector is known for its high standards in tooling, precision machining, and industrial engineering. Among the many grades of tool steels used in the country, 1.3343 and S6-5-2 are two of the most popular for producing high-performance cutting tools, drills, and industrial wear parts. Whether you are a wholesaler, distributor, or end-user, understanding the purchasing process for these steels in Germany can save time, reduce costs, and ensure consistent quality.

Understanding 1.3343 and S6-5-2 Tool Steel

1.3343 (also known internationally as M2 High-Speed Steel) and S6-5-2 are both tungsten–molybdenum high-speed steels. They offer excellent wear resistance, high hardness after heat treatment, and the ability to maintain cutting edges under high temperatures.

- 1.3343: Commonly used for drills, milling cutters, reamers, and cold work punches.

- S6-5-2: Known for its toughness and cutting performance, suitable for applications that demand both wear resistance and impact resistance.

Where to Source These Tool Steels in Germany

When purchasing tool steels in Germany, there are three main sourcing channels:

Local Steel Distributors – Germany has a network of specialty steel suppliers in cities like Düsseldorf, Essen, and Remscheid, where you can find stocked 1.3343 and S6-5-2 in bars, plates, or pre-machined forms.

Direct from Steel Mills – For bulk orders, especially when specific heat treatment or sizes are required, ordering directly from mills or authorized agents can offer better pricing and traceability.

International Suppliers with German Distribution – Many overseas producers maintain German warehouses or partner with local distributors to ensure quick delivery. This option often provides competitive prices without compromising quality.

Purchasing Tips for German Buyers

- Check EN/DIN Standards – Always ensure the material meets DIN EN ISO specifications to avoid compatibility issues in manufacturing.

- Compare Lead Times – Local stock may be faster, but sometimes importing from reputable suppliers with strong logistics can be just as quick.

- Evaluate Machinability Needs – Choose suppliers who can provide annealed or pre-hardened conditions based on your production requirements.

Why Choose FCS Tool Steel for 1.3343 and S6-5-2?

At FCS Tool Steel, we specialize in supplying 1.3343 (M2) and S6-5-2 tool steels to the German market with a focus on quality, consistency, and value.

Our advantages include:

- Extensive Stock Availability – Large inventories of round bars, flat bars, and plates in multiple dimensions, ready for fast dispatch.

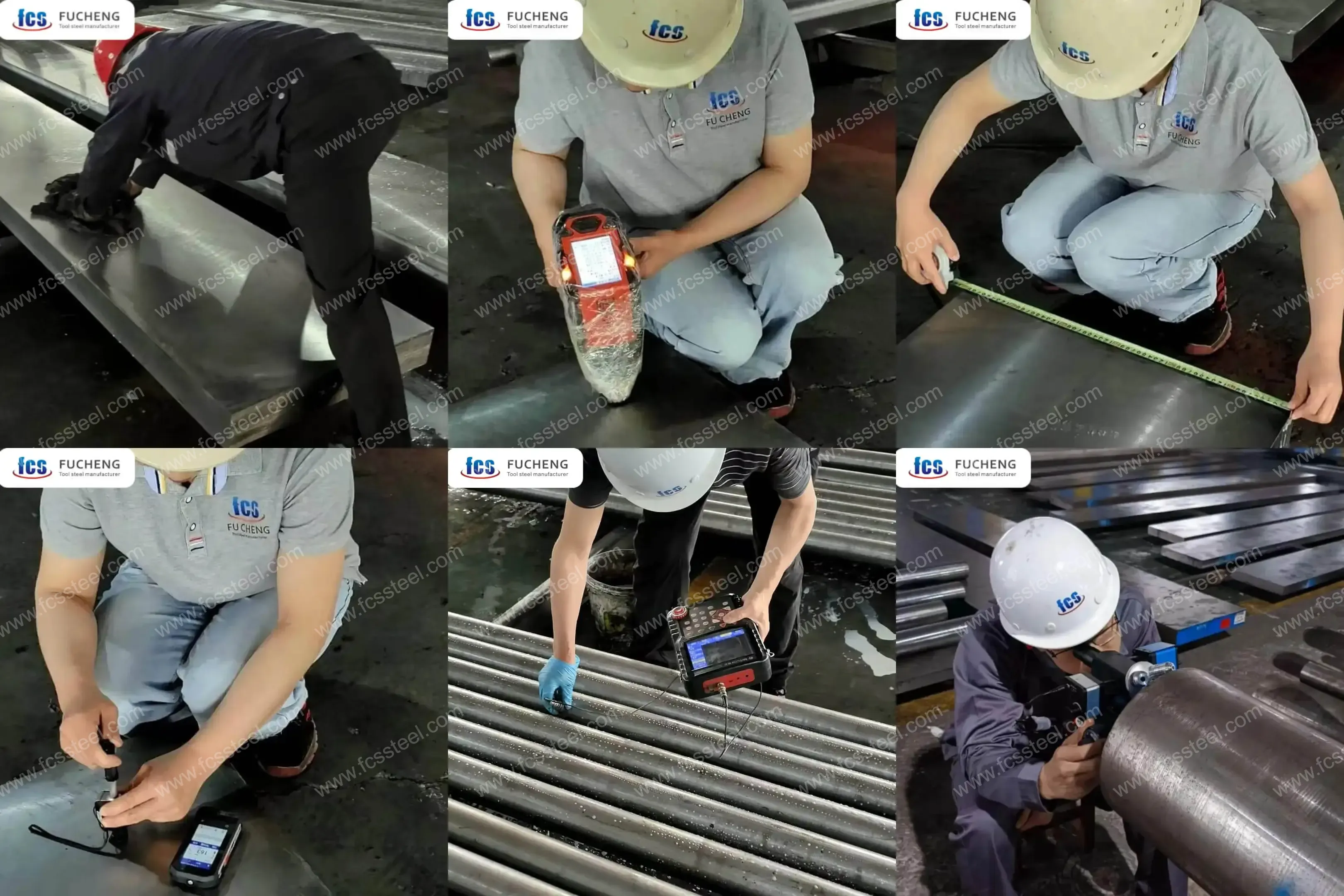

- Precision Processing Services – Cutting, rough machining, and custom heat treatment to meet specific production needs.

- Global Export Experience – Reliable shipping solutions to Germany, ensuring timely delivery and cost control.

- Strict Quality Control – All materials come with full traceability and meet DIN/EN standards.

Whether you are a tool manufacturer in Solingen, a machining shop in Munich, or a distributor serving the automotive industry in Stuttgart, FCS Tool Steel can be your trusted partner for premium-grade high-speed steels.

Summary

Based on my experience with German manufacturers, I suggest choosing a tool steel supplier is about more than just price. I believe you should build partnerships that help you create new and better products.

When you buy quality materials like 1.3343 and S6-5-2 from a good supplier, you get more than steel. In my opinion, you are investing in the high quality and trust that define German engineering.

I find that the right supplier becomes a part of your own production team. They help you uphold the standards that make Germany a top name in manufacturing worldwide.

With the right partner like FCS Tool Steel, you can secure high-quality materials that meet both technical demands and business timelines.