M2 Tool Steel | 1.3343| S6-5-2

FCS Factory offers precision-manufactured M2,1.3343,S6-5-2 High Speed Tool Steel with optimized microstructure, consistent hardness, and excellent heat resistance for demanding industrial cutting, die, and stamping applications.

M2 Tool Steel | 1.3343| S6-5-2 Product Introduction

M2 tool steel (AISI/ASTM standard)

M2 tool steel is a molybdenum-based high-speed steel (ASTM standard) with a typical composition of C 0.78-0.90%, W 5.50-6.75%, Mo 4.50-5.50%, Cr 3.80 -4.40%, V 1.75-2.20%. Its red hardness as the core advantage, in the 500 ℃ high temperature still maintains ≥ 60 HRC hardness, at the same time with uniform carbide distribution and good toughness. However, the heat treatment is easy to overheat, requiring strict control of the quenching temperature (1190-1230 ℃) and protective measures. Mainly used in high-load cutting tools (drills, milling cutters, turning tools) and cold work moulds (punching die, extrusion die).

S6-5-2 Tool Steel (DIN/W-Nr standard)

S6-5-2 tool steel is a tungsten-molybdenum high-speed steel (corresponding to M2) under the Chinese GB/T 9943 standard, with the same composition as M2. Its wear resistance and impact resistance are better than traditional tungsten high-speed steel, annealed hardness ≤ 255 HB, hardness up to ≥ 64 HRC after quenching at 1210-1230℃ and double tempering at 540-560℃ (salt bath furnace). It is suitable for high impact tools (e.g. gear knives, saw blades) and precision cold heading moulds, and is particularly suitable for thermoplastic forming processes.

1.3343 Tool steel (DIN/W-Nr standard)

1.3343 tool steel is a molybdenum-tungsten high-speed steel (grade HS6-5-2C) of the German DIN standard with a composition equivalent to M2/S6-5-2. It is characterised by high hardenability and fine grain organisation, with a hardness of 66 HRC after quenching (oil/gas quenching), but has a significant tendency to decarburise and requires stringent heat treatment protection. Typical applications include complex and valuable tools (broaches, tapping tools), hot rolled drills and EDM moulds, with emphasis on plasticity control in the dynamic recrystallisation temperature range (1150-950°C).

M2 Tool Steel | 1.3343| S6-5-2 Types and Options

The table below shows the size range, surface condition and tolerance details for M2/1.3343/S6-5-2 Tool Steel:

M2 Tool Steel | 1.3343| S6-5-2 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- M2/1.3343/S6-5-2 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

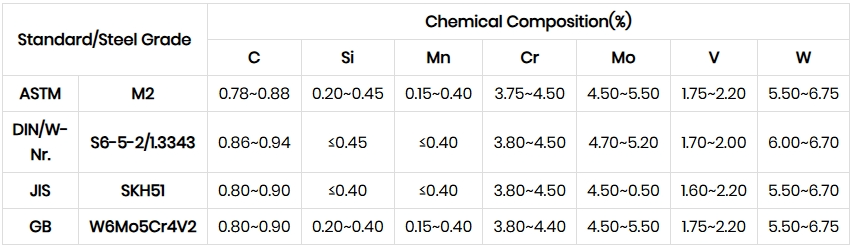

M2 Tool Steel | 1.3343| S6-5-2 Chemical Composition

M2 Tool Steel | 1.3343| S6-5-2 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

M2 Tool Steel | 1.3343| S6-5-2 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

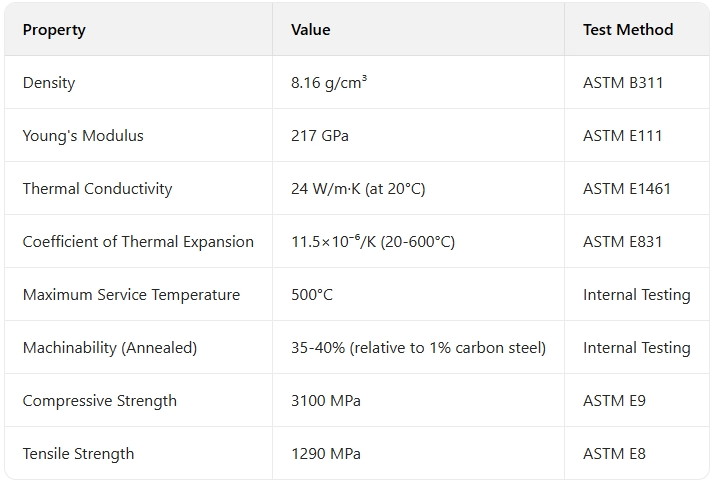

M2 Tool Steel | 1.3343| S6-5-2 Technical Specifications

M2 Tool Steel | 1.3343| S6-5-2 Product Applications

Cutting Tool Manufacturing

M2 tool steel excels in high speed cutting tool applications where heat resistance and edge retention are critical. Our customers use M2 round bar to manufacture drills, end mills, broaches and saw blades that stay sharp even in continuous high-speed operation. The balance of tungsten and molybdenum components provides optimum hot-hardening, enabling cutting tools to operate at speeds up to 30 per cent higher than conventional tool steels.

Industrial moulds and dies

For demanding metal forming operations, M2 steel's excellent compressive strength and wear resistance make it ideal for cold forging dies, precision stamping dies and drawing dies. Our customers report a 40-60% increase in die life when switching to our premium M2 steels, especially in applications where dimensional stability and resistance to pressure distortion are required. Consistent microstructure ensures predictable performance even in complex geometries.

Woodworking Tools

Cabinetmakers and woodworking companies use M2 steels for planer knives, milling cutters and speciality cutting tools where edge retention is critical. The balanced carbide structure provides a clean cutting surface even when grinding engineered and exotic hardwoods. Our precision ground M2 blanks eliminate the need for extensive surface preparation prior to heat treatment, reducing manufacturing time.

Speciality mechanical components

In addition to conventional cutting applications, our M2 steels are increasingly used for highly abrasive mechanical components such as guideways, cam followers and wear plates in speciality machinery. The combination of surface hardness and sufficient core toughness gives excellent service life in applications where conventional steels fail prematurely. Our custom machining service delivers these parts to exact specifications.

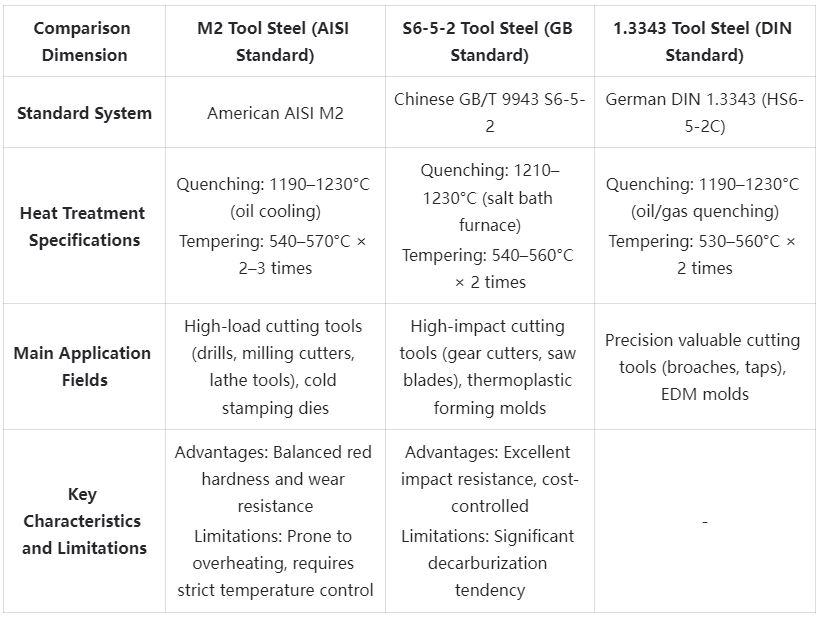

M2 Tool Steel | 1.3343| S6-5-2 Comparison Summary

M2 Tool Steel | 1.3343| S6-5-2 Customer Success Stories

M2 Tool Steel | 1.3343| S6-5-2 Pricing Structure Information

M2 Tool Steel | 1.3343| S6-5-2 Frequently Asked Questions

Q: What are the main differences between M2 and other high speed tool steels?

A: Due to its balanced tungsten and molybdenum composition, M2 offers the best balance of wear resistance and toughness. Compared to T-series steels (higher tungsten) or M-series variants such as M4 (higher carbon and vanadium), M2 offers excellent red-hardness and wear resistance, while maintaining adequate toughness and good manufacturability for most applications.Q: What is the appropriate hardness range for M2 in cutting tool applications?

A: For most cutting tool applications, M2 performs best in the 62-65 HRC range. Critical edges may be targeted at the high end of the highest wear resistance target (64-65 HRC), while applications with shock loads or interrupted cuts may be targeted at the low end (62-63 HRC) to improve toughness. Specific application requirements should determine the final hardness target.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-1-300x300.png)