HSP-41 Tool Steel

HSP-41 is a high-performance special tool steel from Sweden, belonging to the category of hard alloy tool steels. It is used to make single-edge highly wear-resistant cutting tools. This steel grade is designed with high tungsten, molybdenum and chromium content, featuring excellent heat resistance, hardness and wear resistance. It is particularly suitable for use in heavy-load and long-life cutting tools. It is usually referred to as Carbide for cutting tools in foreign materials.

HSP41 Tool Steel Size Range

- HSP41 Hot Rolled Plate/Flat Bar:Thickness: 10-400mm,Width: 200-800mm,Length: 3000-5800mm

- HSP41 Hot Forged Plate/Flat Bar:Thickness: 50-500mm,Width: 50-1500mm,Length: 3000-5800mm

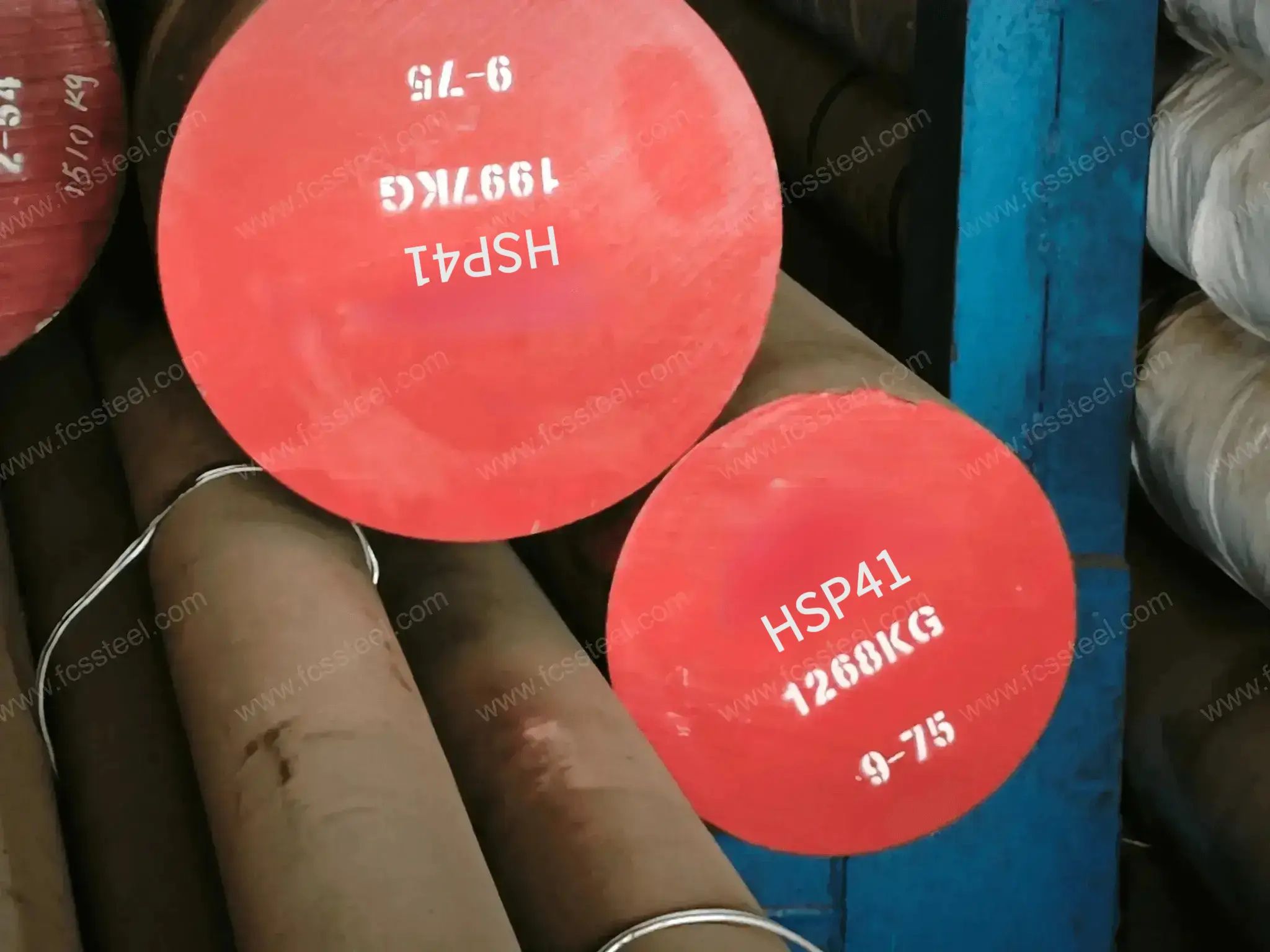

- HSP41 Hot Rolled Round Bar: Diameter 10-65mm,Length 3000-5800mm

- HSP41 Hot Forged Round Bar:Diameter:70-700mm,Length:3000-5800mm

HSP41 Tool Steel Surface Finish

Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

HSP-41 Tool Steel Chemical Composition

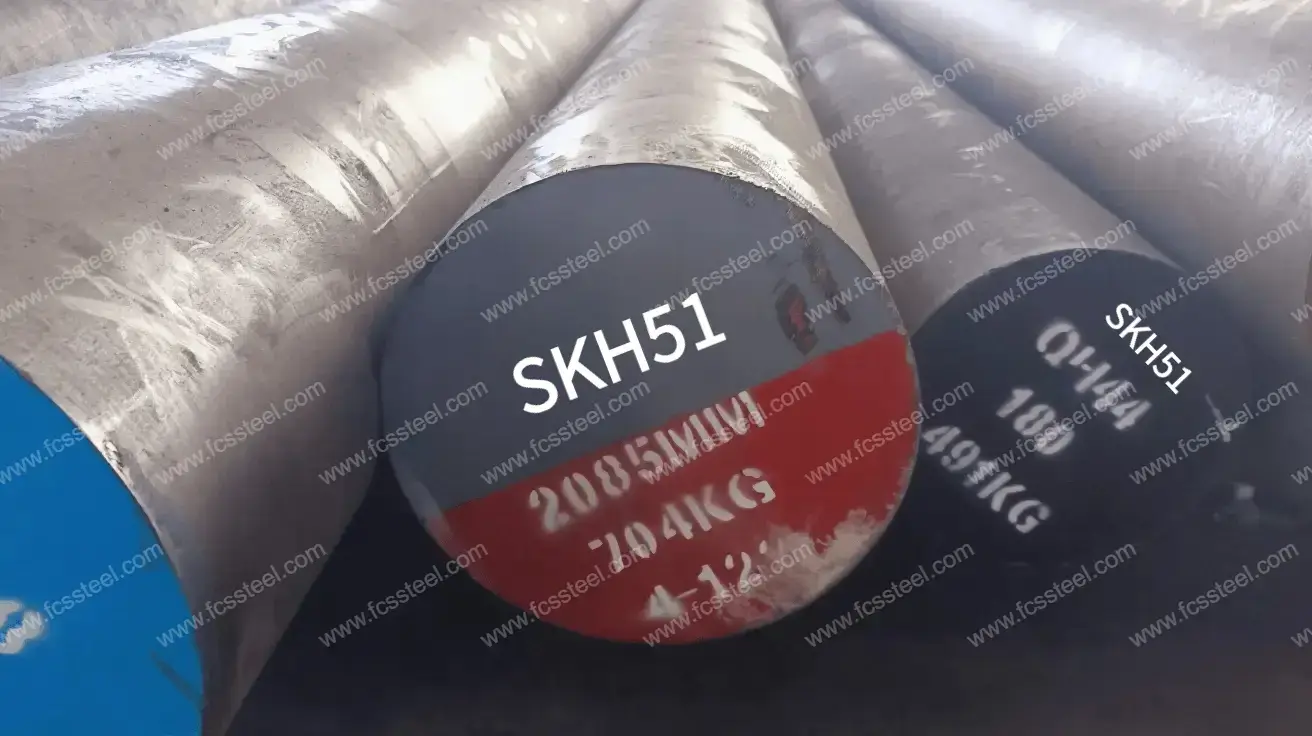

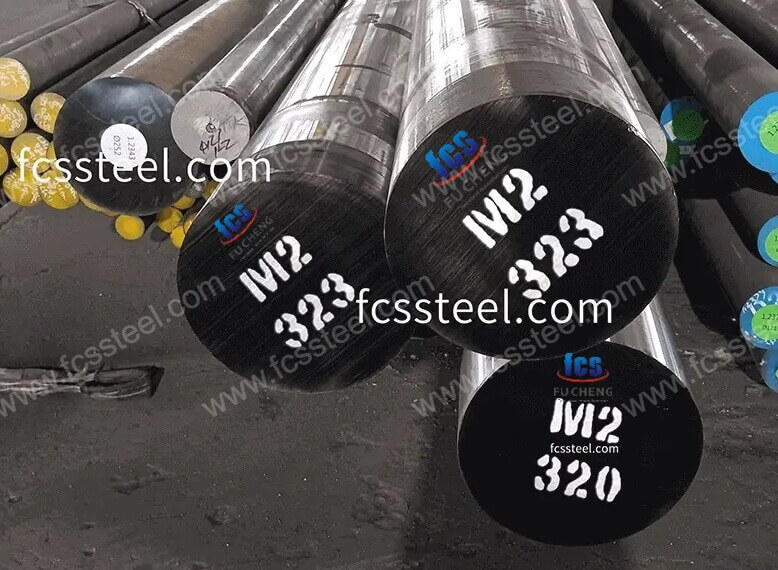

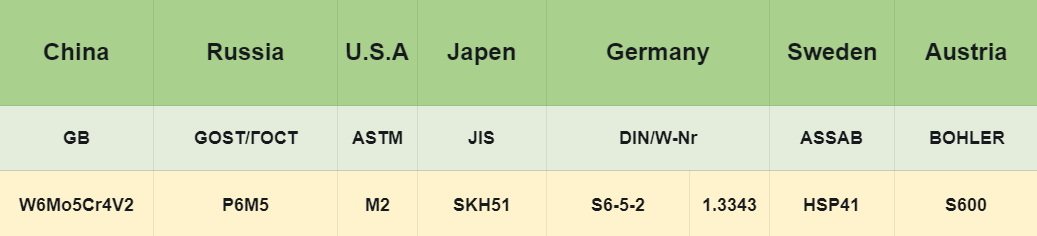

HSP-41 Tool Steel Equivalent Grades

HSP-41 Tool Steel Specifications

HSP-41 Tool Steel Customized Options

- Custom Surface Conditions: Black; Sandblasted; Grinded; Turned/Machined/Milled/Bright

- Custom Chemical Composition: Capable of producing standard grades such as GB, DIN, ASTM, JIS, etc. Chemical composition can be custom-produced individually.

- Custom Specifications: Round steel (diameter) and plates (thickness, width) can be custom-produced.

- Professional packaging for long-term storage or extreme transportation conditions: Including black paint spraying on all sides, plastic film wrapping, anti-rust oil spraying, and delivery in wooden cases.

- Custom production according to samples or technical agreements.

- HSP-41 Tool Steel Electroslag Remelting (HSP-41 ESR): Premium option with higher purity and isotropic properties for critical applications.

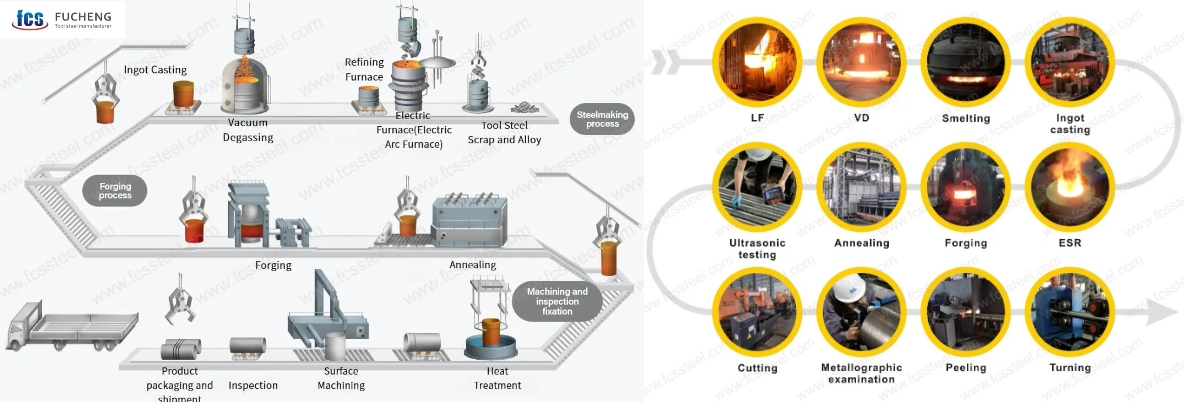

HSP-41 Tool Steel Smelting process

HSP-41 Tool Steel Physical Properties

- Density: approximately 7.0-7.5 kg/dm³

- Tensile strength (Rm) : ≥ 592 MPa; Yield strength (Rp₀.₂) : ≥ 191 MPa

- Impact toughness (Charpy KV) : approximately 32 J; Elongation and reduction of area are both lower than 50 %

- Factory hardness: approximately HB 310-320 (approximately HRC 30)

- Thermal performance: The thermal diffusivity, thermal conductivity and thermal expansion rate are all suitable for long-term application under thermal load conditions

HSP-41 Tool Steel Mechanical & Performance Properties

- Extremely high wear resistance: Due to the uniform network structure formed by tungsten, molybdenum and vanadium carbides, it is very suitable for long-term continuous cutting use.

- Good impact toughness: Unlike many hard steels, it still retains a certain degree of plasticity in a high-hardness state.

- Strong thermal stability: It is not prone to deformation at high temperatures and its hardness remains stable.

- Solderability and repairability: Official data also indicates that it can be repaired by welding or partially reconstructed.

HSP-41 Tool Steel Product Applications

Suitable for making tools that require extreme wear resistance and high-temperature stability, such as:

- Single-edge drill bits, hobs, small punching and shearing tools.

- High-temperature cutting components of special materials.

- High-speed metal cutting and graphite/composite material processing tools, etc.

For industrial use: In environments with high requirements for tool life and large heat loads.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |