HMD-1 Tool Steel

At FCS Tool Steel, we offer HMD-1 Tool Steel in multiple supply conditions:

Supply Condition:Annealed,Machined

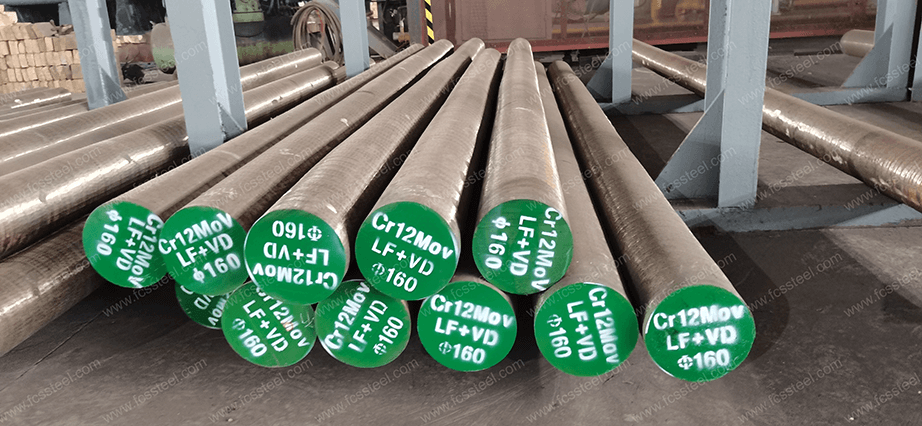

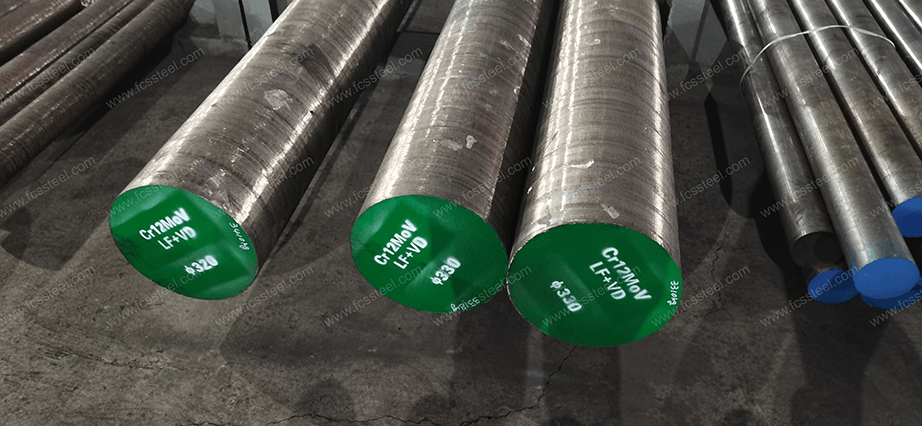

Available Forms:Round bars,Plates / Flat bars,Custom-cut pieces

Processing Services:Sawing,Rough machining,Custom heat treatment.

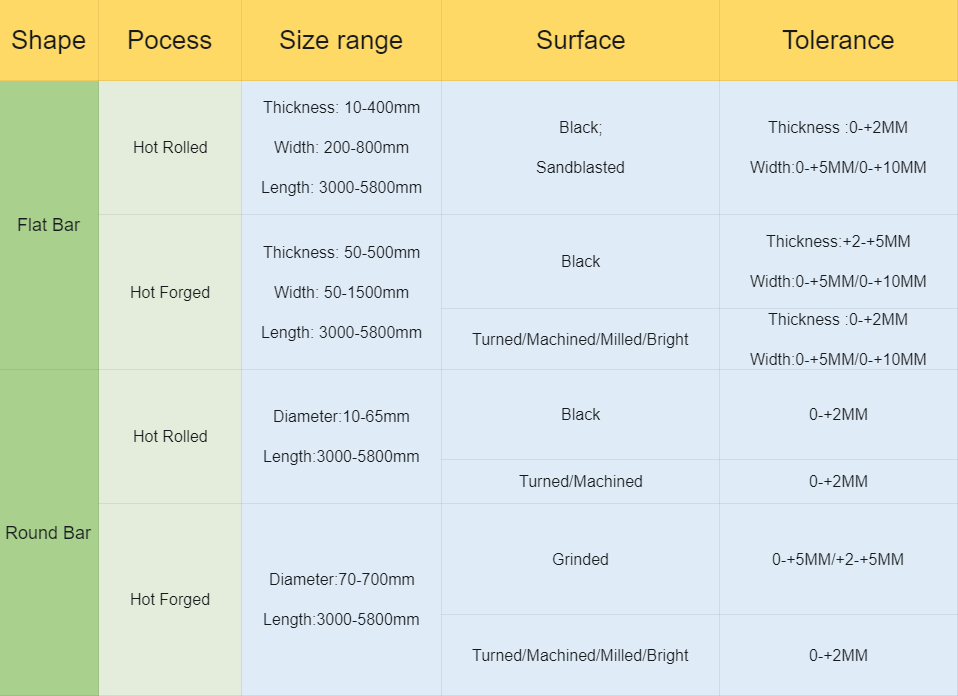

Standard Size Range (Availability varies by stock):

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Forming Methods:Hot Rolled,Hot Forged.

Surface Finish Options:Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

Overview of HMD-1 Tool Steel

HMD-1 Tool Steel is a Japanese high-performance plastic tool steel, originally developed by Hitachi Metals. It is designed for applications requiring excellent toughness, resistance to thermal fatigue, and stability under repeated heating and cooling cycles. Compared with conventional hot work grades such as H13 (1.2344) and H11 (1.2343), HMD-1 offers higher strength retention at elevated temperatures and reduced cracking tendency, making it highly suitable for die-casting and extrusion tooling.This steel is often supplied in annealed condition and later hardened by heat treatment to achieve high hardness and wear resistance while maintaining toughness.

HMD-1 Tool Steel:Product Specification

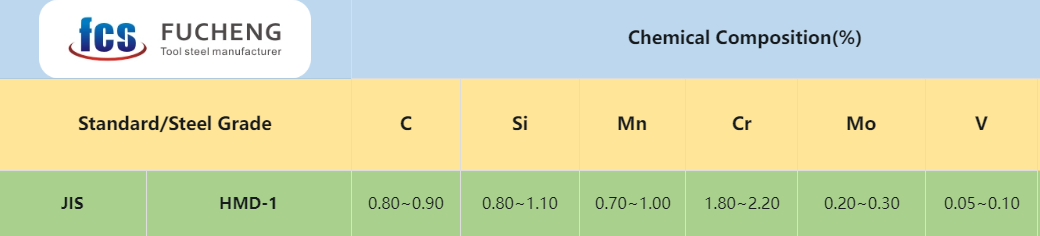

HMD-1 Tool Steel:Chemical Composition

- Carbon (C):0.80–0.90

- Chromium (Cr):1.80 ~2.20

- Molybdenum (Mo): 0.20~0.30

- Vanadium (V):0.05 ~0.10

- Silicon (Si): 0.80~1.10

This balanced alloy composition provides a combination of hot hardness, wear resistance, and toughness, making HMD-1 more durable than standard hot work steels.

Key Properties of HMD-1 Tool Steel

- Excellent Toughness – resists cracking under high-stress tool conditions.

- High Thermal Fatigue Resistance – ideal for repeated heating and cooling operations.

- Good Hot Hardness – maintains strength at elevated service temperatures.

- Improved Die Life – longer lifespan compared with traditional hot work tool steels.

- Dimensional Stability – minimal distortion during heat treatment.

HMD-1 Tool Steel:Typical Applications

HMD-1 Tool Steel is widely used in industries requiring durable hot work tooling:

- Die Casting Dies – especially for aluminum, zinc, and magnesium alloys.

- Extrusion Dies – suitable for non-ferrous metal extrusion.

- Hot Forging Dies – for components needing high impact strength.

- Plastic Molding Tools – when high toughness is required.

- Die Inserts & Sleeves – exposed to repeated heating and cooling.

HMD-1 Tool Steel:Heat Treatment Recommendations

- Annealing: Heat to ~850–900°C, slow cooling in furnace.

- Hardening: Preheat at 600–650°C, then heat to 1020–1040°C, quench in oil or gas.

- Tempering: 3 cycles recommended, 550–650°C, depending on required hardness (target ~46–50 HRC).

HMD-1 Tool Steel:International Equivalent Grades (Reference)

Although HMD-1 is a proprietary Japanese grade, it shares similarities with certain hot work tool steels:

- 1.2344 / H13 (DIN / AISI) – commonly used hot work steel, lower toughness compared to HMD-1.

- 1.2343 / H11 – similar family, but less thermal fatigue resistance.

- SKD61 (JIS) – Japanese standard grade comparable to H13.

- KD11MAX – another Hitachi improved hot work steel, but different balance of toughness and hardness.

HMD-1 Tool Steel:Related Grade Comparison – 86CrMoV7 Tool Steel Equivalents

Since many buyers compare HMD-1 with other tough hot work steels, we include here the international equivalents of 86CrMoV7 Tool Steel for reference:

- DIN EN: 1.2367

- AISI: ~H11 modified / close to H13 variants

- W.-Nr.: X38CrMoV5-3

- JIS: Similar to SKD61 modifications

This helps customers evaluate the best steel grade depending on service environment, tooling demand, and cost-effectiveness.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 135 × 25 cm |

.png)