4Cr13 Tool Steel

4Cr13 Plastic Tool Steel belongs to the martensitic stainless steel family and is meticulously crafted in strict accordance with the GB/T 1220 standard. It is a pillar in the field of plastic mold manufacturing. With its unique chemical composition and exquisite smelting process, it performs outstandingly in key properties such as corrosion resistance, hardness and wear resistance, fully meeting the complex working conditions of plastic molds.

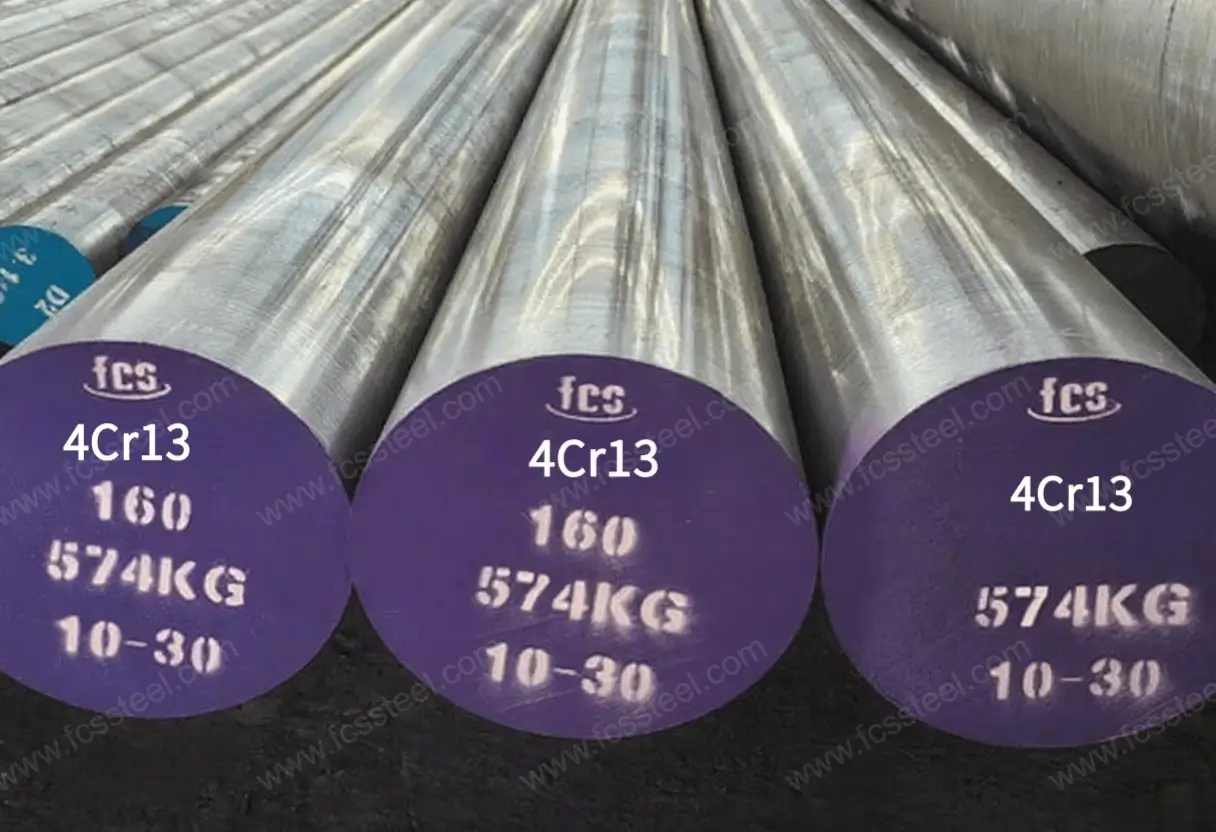

4Cr13 Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

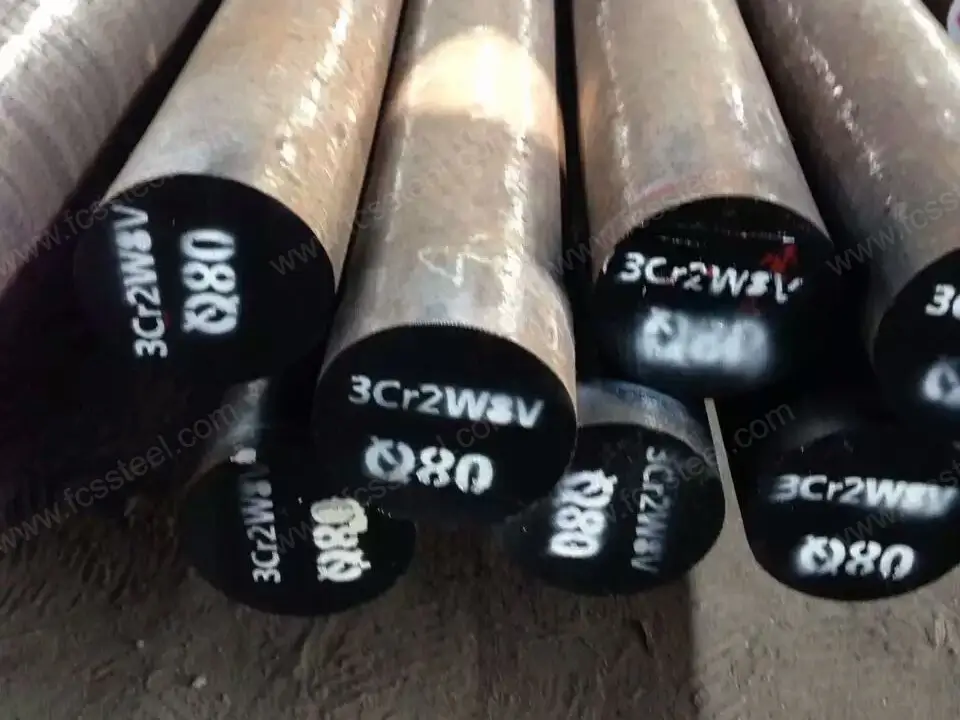

4Cr3Mo3SiV Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

4Cr13 Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

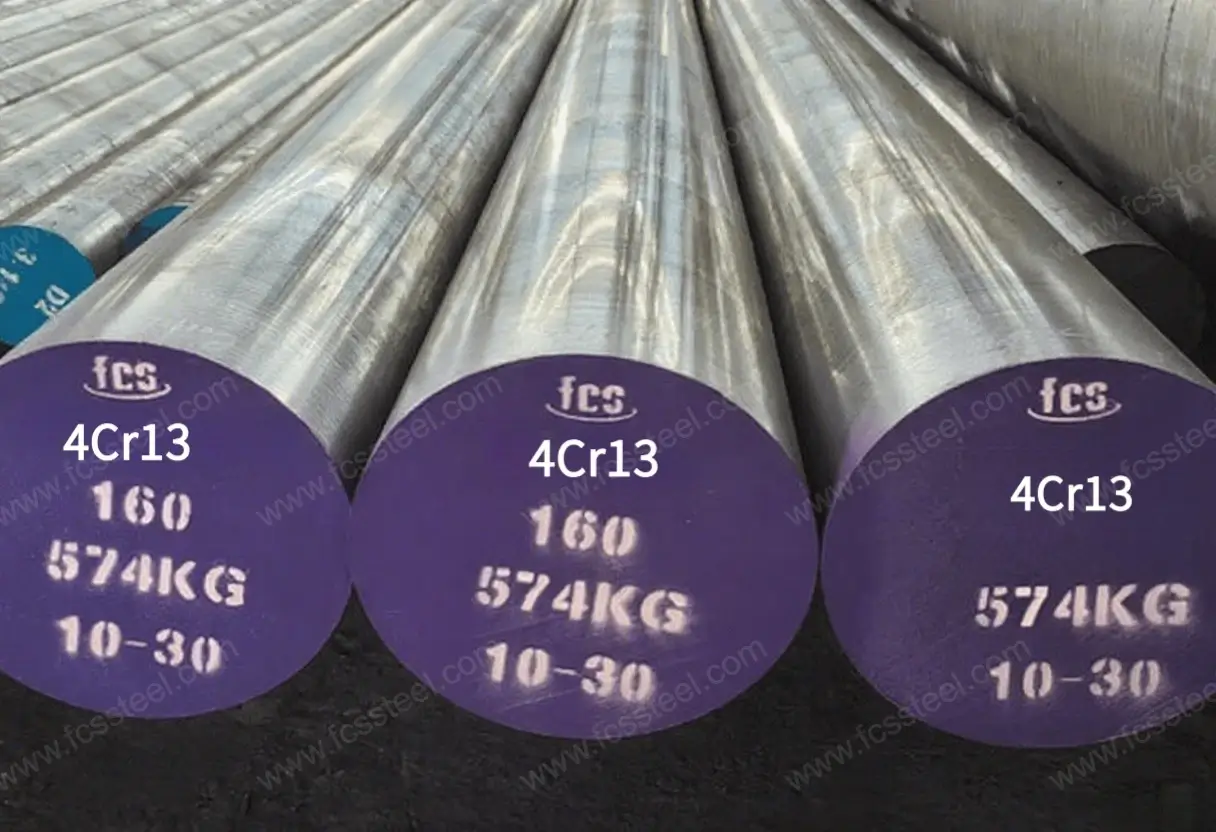

4Cr13 Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

4Cr13 Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

4Cr13 Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is 4Cr13 Tool Steel?

4Cr13 (also known as GB national standard 4Cr13 or 40Cr13) is a martensitic corrosion-resistant plastic mold steel with a chromium content as high as 12-14%. After quenching and hardening, it has high hardness and certain anti-rust properties, making it very suitable for high-mirror injection molds and parts that require wear resistance and corrosion resistance.

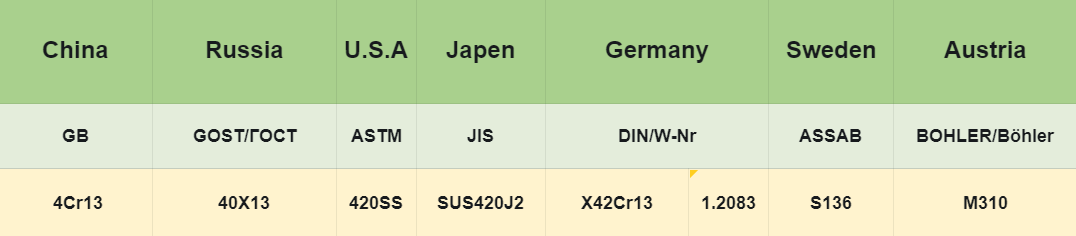

International Equivalent Grades of 4Cr13 Tool Steel

Chemical Composition of 4Cr13 Tool Steel

4Cr13 Steel Product Specifications

4Cr13 Tool Steel:Typical application scenarios

- Injection molds (especially for transparent plastics such as PC, PET, etc., with high mirror finish requirements).

- Food and medical container molds.

- Manufacturing of high mirror finish surface parts, valve cores, nozzles, springs and precision hardware components.

- Other applications that require corrosion resistance, high hardness and smoothness.

Additional information

| Weight | 50 kg |

|---|---|

| Dimensions | 180 × 40 × 30 cm |