1.2767 Tool Steel

At FCS Tool Steel, we offer 1.2767 Tool Steel in multiple supply conditions:

Supply Condition:Annealed,Machined

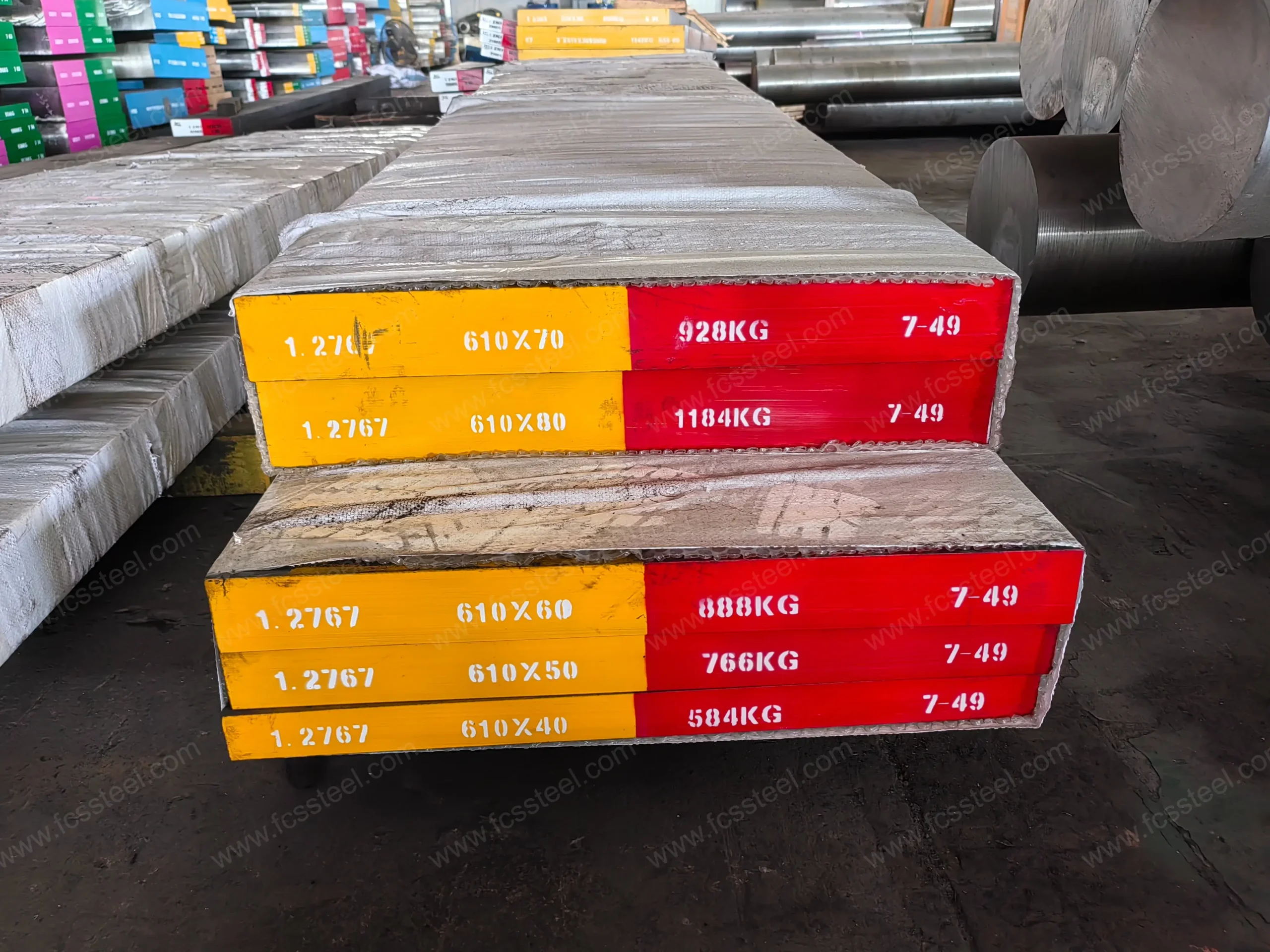

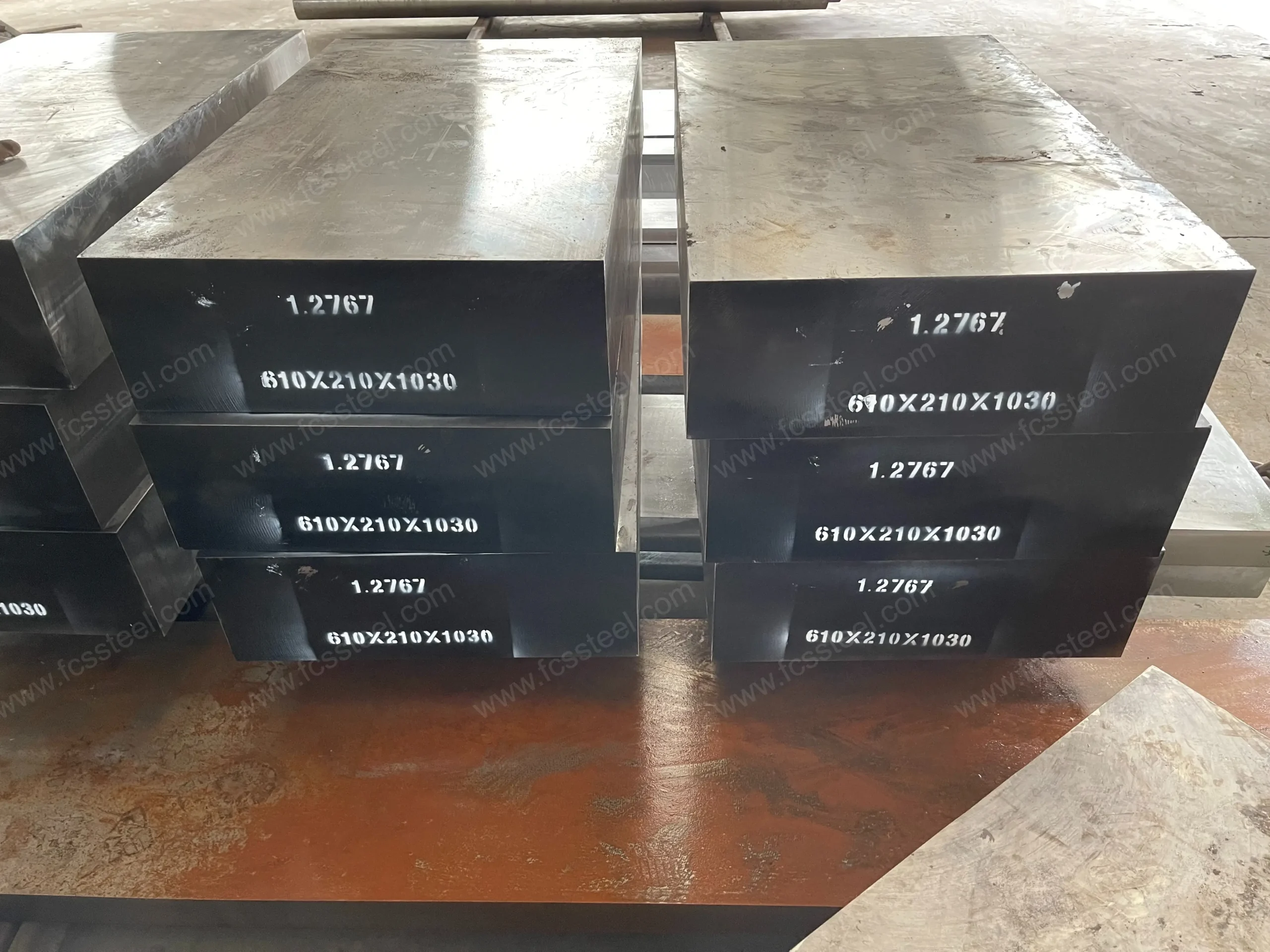

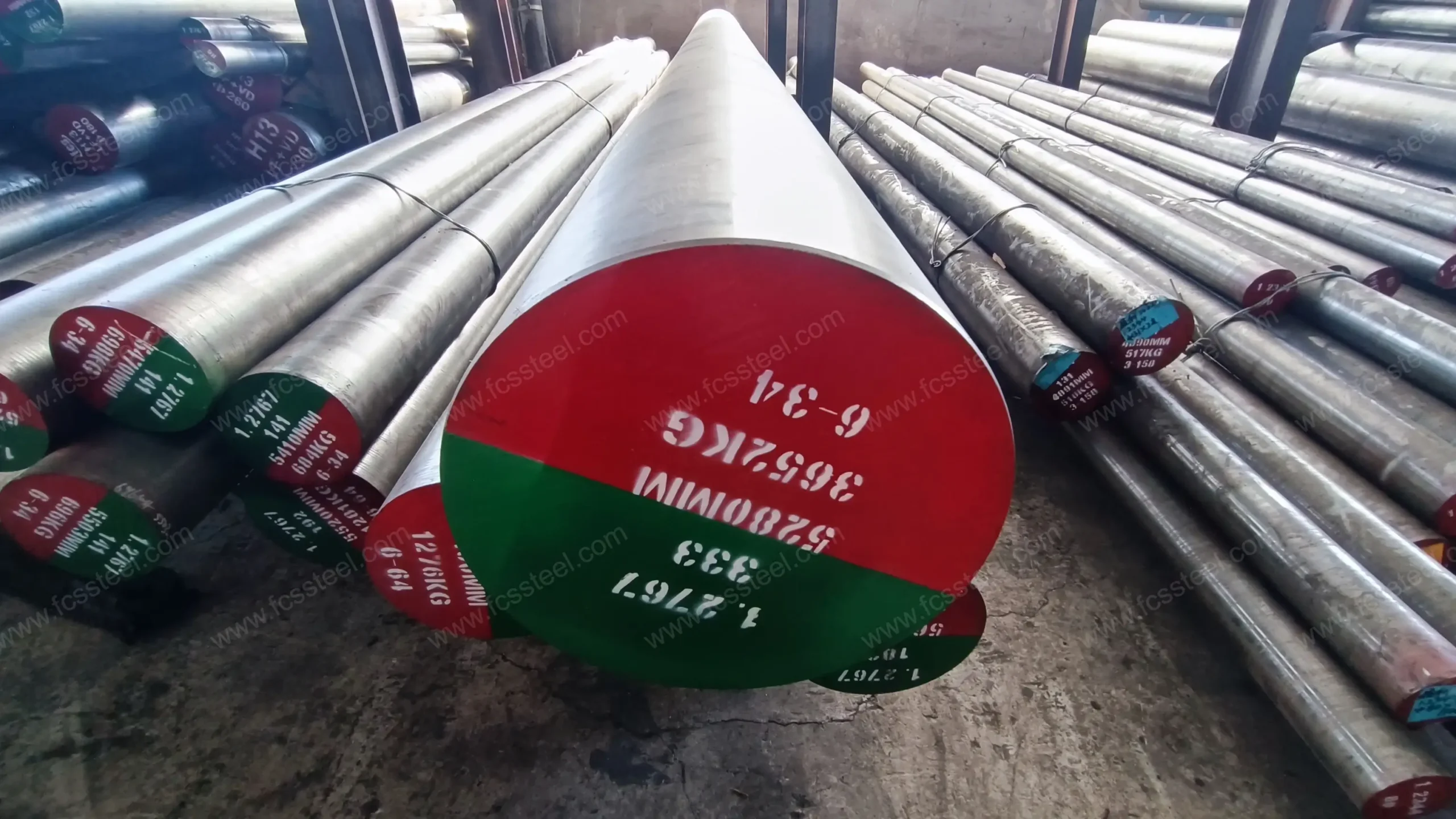

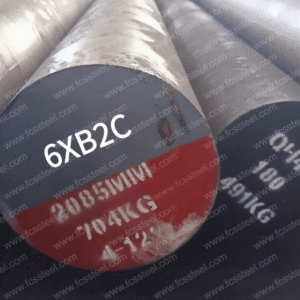

Available Forms:Round bars,Plates / Flat bars,Custom-cut pieces

Processing Services:Sawing,Rough machining,Custom heat treatment.

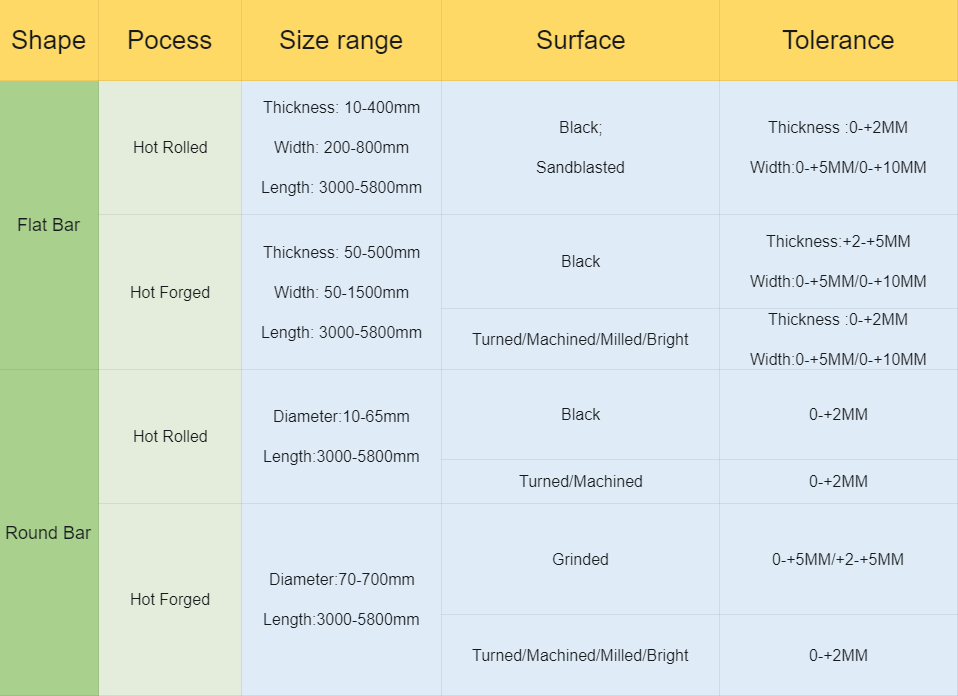

Standard Size Range (Availability varies by stock):

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

Forming Methods:Hot Rolled,Hot Forged.

Surface Finish Options:Black,Grinded,Sandblasted,Turned/Machined/Milled/Bright.

1.2767 Tool Steel:Material Introduction

Cold working tool steel X45NiCrMo4 (1.2767/45NiCrMo16) under DIN standard belongs to nickel-strengthened steel. It features excellent hardenability, high toughness and outstanding polishing performance, making it suitable for manufacturing high-precision, wear-resistant and impact-resistant mold parts. This grade emphasizes structural stability and mirror forming ability, and is suitable for industrial and tool processing requirements.

1.2767 Tool Steel:Product Specification

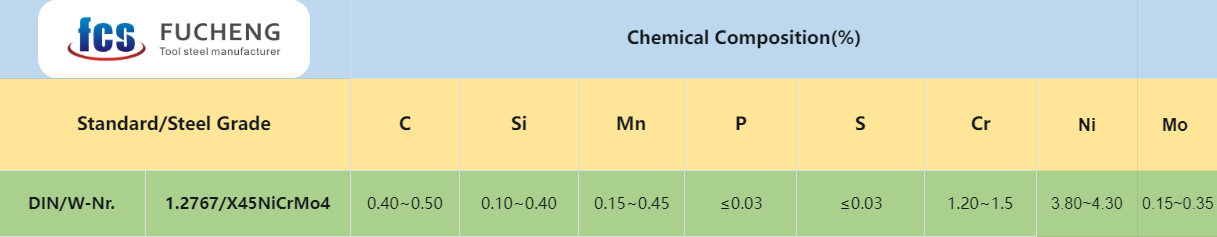

1.2767 Tool Steel:Chemical Composition

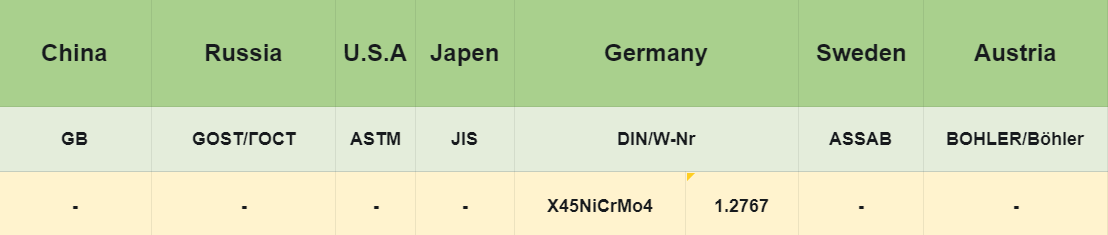

1.2767 Tool Steel Equivalent Grades

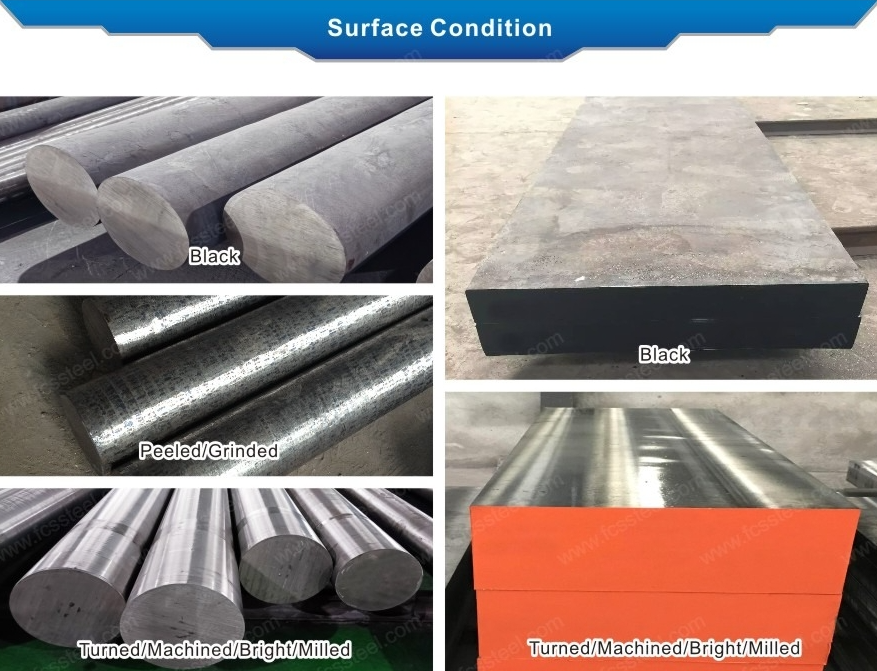

1.2767 Tool Steel:Surface Condition

1.2767 Tool Steel:Milled plate

1.2362 Tool Steel:Turned and Peeled Round Steel

1.2767 Tool Steel:Sandblasted Round Bar

1.2767 Tool Steel:Heat treatment suggestions (Reference Process)

- Annealing: Heat to 610-650 °C, cool slowly to ≤ 260 HB (softened state).

- Quenching: Heat to 840-870 °C → Quench in oil or air.

- Tempering: 200-600 °C (multiple times). By choosing an appropriate temperature, a hardness range of 38-56 HRC can be achieved.

- The relationship between hardness and tempering temperature: 100 °C → 56 HRC; 300 °C → 50 HRC 600 °C → 38 HRC.

- Suggestion: Perform stress relief tempering after processing. If working at 200 °C, it is recommended to temper to at least 250 °C.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 135 × 25 cm |