Introduction:

Manufacturing relying on trust. Material quality is more than just a detail on a paper. It supports your whole schedule.

Pick FCS Tool Steel. You get more than just metal. You get results you can count on.Every bar passes tough tests before it hits your shop. We check the chemicals. We screen the structure.

Our team finds and cuts out defects that others miss. This prevents bad breaks. Your lines stay running without failures that the lab should have caught.

FCS Tool Steel: Chemical Checks and Cutting Out Bad Steel

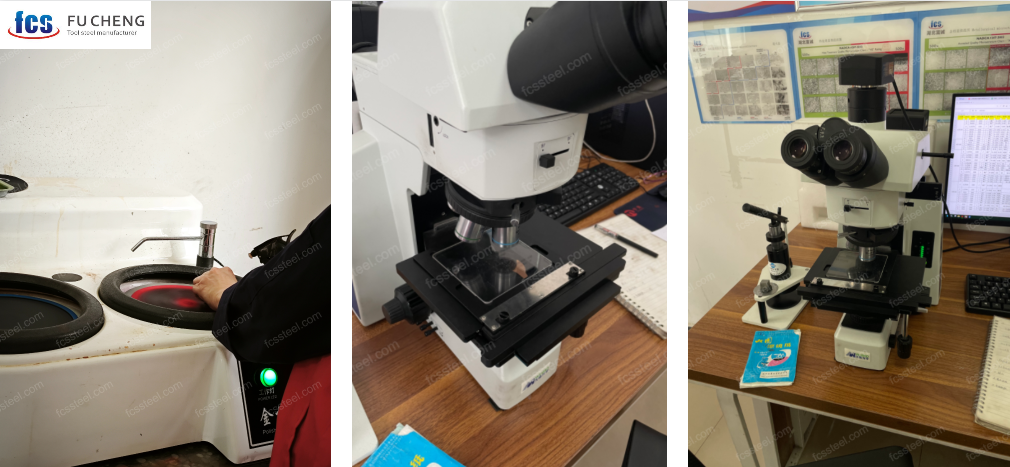

Metallographic analysis Ultrasonic Testing

Metallographic analysis Ultrasonic Testing

FCS Tool Steel starts with strict chemical testing. Each batch needs to meet exact specs. We follow three major standards: ASTM A681 for US markets, DIN EN ISO 4957 for Europe, and JIS G4404 for Japanese precision.

Our testing protocols focus intensely on four critical elements that define steel performance:

Key Alloying Elements in Steel

| Element | Primary Functions & Characteristics |

| Carbon (C) | The most vital element; determines hardness and wear resistance. |

| Chromium (Cr) | Essential for corrosion resistance and deep hardening capabilities. |

| Molybdenum (Mo) | Provides the strength needed to withstand high-heat environments. |

| Vanadium (V) | Refines grain structure, adding toughness to prevent chipping. |

Why Chemical Precision Stops Production Problems

Small changes in element ratios cause big problems later. Just 0.05% carbon difference can change how steel responds to heat treatment. Your D2 tool steel might crack during hardening. Your H13 hot work steel could fail under heat cycling. Your S7 steel shock-resistant grade might lose toughness.

FCS monitors at multiple stages. Spectroscopic analysis runs right after melting. Second checks happen during ingot formation. Final tests validate every billet before cutting and shipping.

Steel outside tolerance ranges gets cut out. No bad steel enters the supply chain. This strict approach costs more upfront. But it prevents expensive mold failures in your shop. You avoid replacing failed tools. You skip production downtime. You get consistent results every time.

The right chemical balance gives you predictable performance. Your tools work as expected. Heat treatment produces the hardness you need. The steel handles your specific application.

FCS Chemical Detection Equipment & Process

Optical Emission Spectrometers (OES) power the FCS Tool Steel detection lab. These machines check element content down to parts-per-million levels. A single spark creates a spectral signature. Software matches that signature against stored element profiles. You get results in 30 seconds.

The OES unit checks 15+ elements at once. Carbon, chromium, molybdenum, vanadium, manganese, silicon, nickel, and trace contaminants all show up in one scan. No guesswork. No estimates. Just pure data.

Carbon-Sulfur Analyzers handle what OES can’t catch with exact precision. These machines burn small steel samples in pure oxygen. Infrared sensors pick up CO2 and SO2 levels released during burning. This method gives carbon readings accurate to ±0.001%. Sulfur content gets the same exact treatment.

Why two systems? Carbon controls hardness in FCS Tool Steel. Sulfur causes brittleness problems even at 0.02%. Both need special equipment for reliable checks.

Sample Testing Protocol Throughout Production

FCS doesn’t test once and call it done. We run checks at three key points.

- Heat Analysis starts right after melting. Technicians pull molten samples from the furnace ladle. Fast analysis confirms chemistry before pouring ingots. Off-spec melts get fixed on the spot. Adding ferroalloys fixes what’s missing. Pure iron dilution cuts down excess elements.

- Refining Phase Verification happens during secondary steelmaking. Argon oxygen decarburization (AOD) or vacuum arc remelting (VAR) shifts chemistry a bit. Mid-process testing spots drift before it grows. Operators adjust treatment based on live data.

- Product Analysis checks every production lot before cutting. Final billets go through destructive sampling. Lab techs cut small sections, machine them smooth, and run full scans. Each element must stay within tolerance. Documentation goes with every shipment.

Third-Party Validation Option

Customers wanting extra proof can request outside testing. FCS partners with SGS and TÜV inspection services. These global bodies run their own labs and standards. They test random samples from your order without knowing what to expect.

Third-party reports hold legal weight in trade disputes. They meet quality needs for aerospace, medical device, and automotive uses. The extra cost runs 2-3% of order value. For critical uses, that investment stops failures that could cost millions.

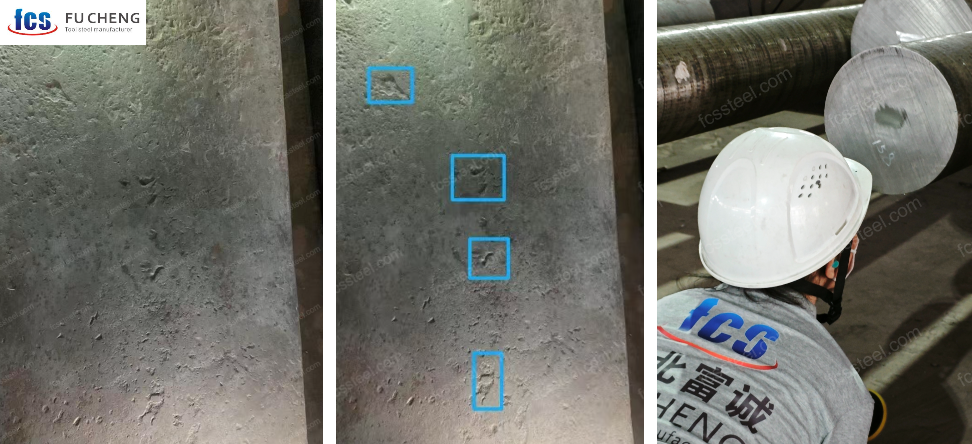

Identifying Common Tool Steel Defects

Tool steel defects generally fall into two buckets: chemical imbalances and physical flaws. Both are silent killers of tool performance if they slip past QC.

FCS Tool Steel screening catches the invisible problems. A billet might look perfect on a spec sheet but hide internal weaknesses that snap under pressure.

1. Chemical Composition Defects

These occur when the elemental “recipe” is off. The steel might look right, but it won’t behave right.

Carbon Deviation: Checks against target levels (e.g., 1.50% for D2 steel). If carbon drifts even slightly (to 1.45% or 1.55%), heat treatment becomes a gamble. Your steel might crack during quenching or end up too soft to cut.

Alloy Segregation: Elements cluster unevenly during cooling, creating “hard spots” and “soft spots” in the same bar. This makes machining a nightmare and can cut tool life by 30-40%. We use macro-etching to spot these banding patterns before they ship.

2. Physical Structural Defects

These are actual structural breaks or voids inside the metal matrix.

Internal Porosity: Tiny voids (micro-holes) left by escaping gases. They act as stress risers. A die rated for 500,000 cycles might fail at 200,000 because fatigue cracks start right here.

Gas Holes: Larger trapped bubbles (2-5mm). If machining exposes one, you have a permanent stress point. Under load, the tool will crack from exactly this spot.

Slag Inclusions: Non-metallic debris (oxides/sulfides) trapped in the melt. Since they don’t bond with the steel, they act like internal notches, causing immediate failure under impact.

Internal Cracks: Caused by thermal shock when the surface cools faster than the core. You can’t see them with the naked eye, but they are ticking time bombs waiting for service stress.

3. Advanced Detection Standards for FCS Tool Steel

Ultrasonic Testing (UT) acts as our internal radar, serving as the backbone of physical defect screening. While many suppliers settle for basic Class B standards, FCS follows the stricter SEP 1921 protocols at Class C/c or D/d levels.

Using high-frequency sound waves, our equipment maps the internal structure of every billet in three dimensions. Defects as small as 1mm create distinct echoes that our system flags immediately.

Class C/c Standard: Zero defects allowed above 1.5mm diameter.

Class D/d Standard: Pushes limits even further for critical applications. No flaws larger than 1.0mm pass inspection.

If the scan finds a problem, we cut that section out. The remaining clean steel moves forward. This process reduces our material yield, but it guarantees that you receive only 100% defect-free material.

The FCS “One-Strike” Protocol: Defect Removal Process

Bad steel never reaches your production floor. We treat defects with a simple, non-negotiable rule: if it fails a test, it stops moving. Here is exactly how we scrub the supply chain clean before shipping.

Step 1: Immediate Digital Flagging

The moment a chemical check or ultrasonic scan shows a deviation, the system locks down that specific billet.

Digital Tagging: The failed piece gets a unique barcode linking to its failure report (e.g., “high sulfur” or “internal void”).

Data Storage: We keep the full record—defect type, location, and severity—in our database for quality tracking.

Step 2: Physical Quarantine (The “Red Tag” Zone)

Software isn’t enough; we need physical barriers to stop human error.

Visual Warning: Bright RED tags go on the material instantly.

Isolation: Forklift operators move the flagged stock to a fenced-off quarantine area. This zone is locked. Only QC staff hold the keys.

Zero Mix-ups: This prevents a tired worker on a night shift from accidentally loading a bad bar onto your truck.

Step 3: Surgical Extraction

We don’t just cut randomly. Using the 3D data from our Ultrasonic scans, we treat the steel like a surgeon treats a patient.

Crop Ends: We slice off the ends first, removing shrinkage holes from casting.

Surface Peeling: Seams and shallow cracks get machined off.

Precise Defect Removal: Heavy-duty bandsaws cut out internal flaws with a 5mm safety margin. We re-scan the remaining piece to confirm it’s now 100% clean.

The Financial Outcome: You Don’t Pay for Scrap

This is the most important part for your budget. If a 500kg billet loses 75kg during this cleaning process, that loss belongs to FCS.

You only pay for the verified, usable steel that arrives at your dock. We absorb the cost of the waste so you don’t inherit the risk.

FCS Quality Control Certification

FCS Tool Steel holds full ISO 9001:2015 certification, but for you, this means more than just a plaque on our wall. It means consistency.

In the steel trade, the biggest risk is variation—getting a perfect batch one month and a problematic one the next. Our ISO certification acts as your insurance policy against that volatility. It forces us to document every step, review every error, and prove that our process is stable. You aren’t just buying steel; you are buying a repeatable manufacturing process.

1. Industry-Specific Quality Standards

General standards work for general parts. But if you are machining components for aerospace turbines, medical implants, or high-stress automotive gears, “standard” isn’t good enough.

FCS guarantees the high-purity levels these industries demand. We control the “enemies” of steel life—sulfur, phosphorus, and oxygen—that make metal brittle.

- Medical Grade: We keep sulfur below 0.008% for surgical tools, far stricter than the commercial 0.030% limit.

- Fatigue Resistance: By reducing non-metallic inclusions, we extend the fatigue life of parts that verify safety.

2. Complete Heat Traceability System

When an auditor walks into your facility asking about material origin, you need answers immediately. The FCS Heat Number system gives them to you.

Every billet carries a unique stamped code that acts like a “black box” recorder. It traces the history back to the original furnace melt. You can see exactly which batch of iron ore was used, what temperatures were hit during refining, and the exact date of the ultrasonic test. This isn’t just data; it’s legal proof of quality for your compliance records.

Verification Documentation: Your Quality Shield

Every FCS Tool Steel shipment arrives with a complete verification package. These aren’t generic, rubber-stamped forms. They are precise records of the exact metal sitting on your dock.

1. The Mill Test Certificate (MTC)

We follow strict EN 10204 3.1 standards. This means an independent inspection authority—separate from the manufacturing floor—verifies the test steps and signs off on the results before a single document is issued.

Crucially, we believe in raw data transparency. We don’t hide behind “Pass” or “Within Spec” checkboxes. Your certificate shows the actual measured numbers next to the standard limits:

- If Carbon measures 1.52% against a 1.45-1.55% range, you see “1.52%”.

- If Chromium hits 11.8%, that exact figure is recorded.

This level of detail allows your engineers to fine-tune heat treatment parameters based on the actual chemistry, not just the theoretical one.

2. Physical Integrity Reports

Chemistry is only half the story. Our documentation package proves the steel is sound from the inside out.

Hardness Validation: We don’t rely on averages. The certificate lists multiple Brinell (HB) readings taken across the billet surface, so you can spot any hardness variations instantly.

Ultrasonic Proof: For critical aerospace or medical orders, we attach the digital UT scan images. You get a 3D map of the internal structure, proving that the material passed SEP 1921 Class C/c standards.

3. Audit-Ready Compliance

Whether you are facing a supplier review from an automotive giant or filing FDA trace rules for medical devices, our paperwork is ready. FCS Tool Steel delivers the documented proof your quality team needs to close audits fast.

Conclusion

The math is simple. Upfront savings on budget steel vanish the moment a tool cracks. With FCS Tool Steel, you get certainty.

We handled the risk for you. We scrap bad metal so you never face it. Don’t just take our word for it. Demand the data. Ask for ultrasonic scans. Stop gambling with your production schedule. Switch to vetted material that guarantees performance.