In today’s increasingly competitive manufacturing landscape, buyers across industries such as die-casting, injection molding, and forging face continuous pressure to secure tool steels that can deliver superior performance while keeping overall procurement costs manageable. Among the wide variety of hot-work tool steels, 1.2344 (commonly cross-referenced with H13) stands out for its excellent combination of heat resistance, toughness, and durability. Because of its versatile use in high-temperature tooling applications, global demand for this grade has been rising steadily.

While many buyers rely on traders or stockists, a growing number of industrial procurement managers, wholesalers, and distributors are beginning to prioritize direct cooperation with tool steel factories. This approach elimina

tes layers of middlemen, ensures better technical alignment, and creates stronger long-term partnerships. To fully understand the value of this strategy, it is useful to examine six distinct advantages of direct cooperation with.

1. Superior Cost-Effectiveness by Eliminating Intermediaries

One of the most immediate benefits of working directly with a factory is the significant reduction in overall procurement costs. When distributors or brokers enter the supply chain, they add a margin to cover their services. These markups often inflate the final steel price substantially, especially for high-volume orders.

By contrast, direct procurement means the buyer is engaging with the producer at the source. This model eliminates unnecessary costs, enabling more competitive pricing per ton. For example, a European buyer sourcing 200 tons of 1.2344 might pay a 15–20% premium through a third-party trader compared to direct contracts with the manufacturer. Over time, such differences can dramatically affect profit margins for companies engaged in tooling production.

Moreover, factories can offer volume-based discounts when negotiating directly. Since they understand production planning and rolling schedules, they may bundle orders or synchronize production runs to optimize cost efficiency. These savings can be strategically reinvested into areas such as logistics improvements, further boosting competitiveness in global markets.

2. Uncompromised Quality Assurance and Material Consistency

The quality of 1.2344 tool steel is a defining factor in its performance. Even minor deviations in chemical composition, heat treatment, or hardness can compromise the steel’s ability to withstand extreme heat cycles in die-casting or hot extrusion. When buyers work through intermediaries, it becomes harder to verify whether the steel has been sourced from the original mill, whether secondary processing has altered its properties, or whether proper storage and transport conditions have been maintained.

Direct cooperation with factories provides greater confidence in material consistency. Buyers gain clear visibility into:

- Melting processes (electric arc furnace or vacuum degassing)

- Chemical composition controls to ensure compliance with EN, ASTM, or JIS standards

- Heat treatment records, including quenching and tempering cycles

- Testing data such as Charpy impact results, hardness values, and ultrasonic inspection reports

Factories often issue mill test certificates (MTCs) and allow buyers to verify results with third-party laboratories. In addition, long-term collaboration can lead to customized quality protocols—for example, setting stricter tolerance ranges for impurities like sulfur or phosphorus. This ensures the buyer receives batches of steel that are uniform, predictable, and less prone to failure during service.

In industries where tool replacement downtime translates into lost productivity and higher costs, uncompromised quality assurance becomes an indispensable advantage.

3. Direct Access to In-Depth Technical Expertise and R&D

Factories that specialize in 1.2344 tool steel typically operate with dedicated metallurgy and R&D teams. These experts are not only familiar with the production side but also understand the specific requirements of end-use applications such as forging dies, extrusion tooling, and injection mold inserts.

When buyers engage through trading companies, this knowledge is often diluted or unavailable. By contrast, direct engagement with a factory opens a channel for technical collaboration. Buyers can:

- Seek advice on optimal hardness ranges for particular applications.

- Request guidance on surface treatments such as nitriding or PVD coatings.

- Evaluate the performance of comparable grades, such as D2 steel or 1.2379, when assessing specific tooling challenges.

- Collaborate on new alloy development projects, especially for demanding applications in aerospace or automotive die-casting.

For instance, a manufacturer producing aluminum die-casting molds might face premature cracking due to thermal fatigue. By working directly with the factory, they can discuss customized tempering cycles or explore alternative microalloyed variations of 1.2344 to extend tool life. Such cooperative problem-solving is rarely possible when communication is filtered through intermediaries who lack metallurgical expertise.

Ultimately, this access to in-house technical support transforms the relationship from a transactional supplier-buyer model into a strategic partnership that drives innovation and long-term value.

4. Greater Customization Capabilities and Production Flexibility

Tooling requirements vary widely across industries, and even within the same sector, dimensions, hardness profiles, and surface conditions may differ from project to project. Direct cooperation with 1.2344 tool steel factories allows buyers to tap into the customization capabilities of the production line.

Factories can tailor:

- Dimensions and shapes: from standard bars and plates to custom pre-machined blocks.

- Hardness ranges: adjusted through quenching and tempering for specific wear resistance or toughness needs.

- Surface finishes: ground, milled, or machined for faster downstream use.

- Heat treatment options: annealed or pre-hardened, depending on customer requirements.

Additionally, factories can adapt production scheduling to match the buyer’s timelines. For example, if an automotive tooling supplier in Asia requires urgent delivery for a new die-casting project, the factory may prioritize the rolling of 1.2344 billets in its upcoming batch. Such agility minimizes lead times and ensures that buyers can respond quickly to market demands.

This level of flexibility is rarely achievable when orders pass through multiple intermediaries, each adding complexity and delays to the process.

5. Optimized Supply Chain with Enhanced Reliability and Speed

Global industries depend on reliable supply chains to avoid costly downtime. Delays in receiving tool steel can disrupt entire production schedules. Direct cooperation with factories strengthens supply chain reliability by cutting unnecessary steps and providing clearer timelines.

Factories typically maintain large inventories of semi-finished products, allowing them to meet both small and bulk orders promptly. With direct visibility into stock levels and rolling schedules, buyers can plan their procurement cycles more effectively.

Moreover, direct relationships often involve integrated logistics planning. Some factories maintain partnerships with shipping agents, enabling smoother coordination for sea freight or air cargo. When sudden shifts in demand occur—such as the surge in injection mold demand during rapid growth in consumer electronics—factories with flexible logistics can adjust quickly to maintain delivery commitments.

Enhanced reliability is especially critical in international trade. For example, a European distributor working with a 1.2344 factory in East Asia benefits from real-time updates on production progress and shipping schedules, rather than waiting for indirect communication through multiple brokers. This transparency minimizes risks and ensures higher confidence in delivery speed.

6. Complete Traceability and Guaranteed Certification Compliance

Today’s industrial buyers face increasing regulatory and compliance requirements. From ISO quality management standards to environmental certifications, supply chain transparency is essential. When sourcing through intermediaries, traceability becomes more challenging—buyers may not always know the exact origin of the steel or whether certifications are authentic.

Direct factory cooperation guarantees full traceability from raw material selection to final shipment. Factories document every stage of the process, including:

- Origin of raw materials

- Melting and refining history

- Heat treatment cycles

- Non-destructive testing and inspection reports

- Final mechanical property certifications

This ensures the steel meets international benchmarks such as EN 10204 3.1 or 3.2 certification standards, giving buyers confidence in compliance for both internal audits and external customer requirements.

Furthermore, factories increasingly invest in sustainable production practices, such as electric arc furnace steelmaking with higher scrap utilization and reduced carbon footprints. By cooperating directly, buyers can align their procurement policies with global sustainability goals, further strengthening their market reputation.

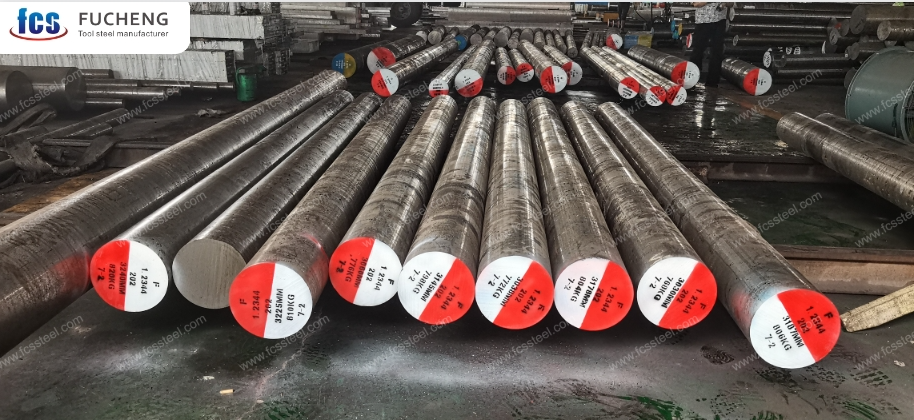

Partner with FCS Tool Steel Factory for Reliable 1.2344 Solutions

When it comes to sourcing 1.2344 tool steel, buyers often search for more than just competitive pricing—they seek trust, flexibility, and long-term stability. This is exactly where FCS Tool Steel Factory (also known as Fucheng Tool Steel) delivers exceptional value. With deep production experience and a strong commitment to international buyers, FCS goes beyond simple supply to act as a strategic partner.

Instead of facing uncertainties in quality or delivery, you can count on ready inventories, consistent metallurgy, and export-focused logistics tailored to your schedule. FCS also welcomes collaborative projects, allowing you to request custom sizes, tailored heat treatments, or surface preparations that match your application needs.

If you are a wholesaler, distributor, or manufacturer looking to strengthen your sourcing strategy, now is the time to act. Reach out to FCS Tool Steel Factory and secure a partnership that guarantees dependable 1.2344 tool steel supply—helping you cut costs, shorten lead times, and stay competitive in your market.

Conclusion: Building Strategic Value Through Direct Cooperation

Direct cooperation with 1.2344 tool steel factories provides a wealth of advantages that extend far beyond cost savings. By eliminating intermediaries, buyers gain cost-effectiveness, assured quality, technical expertise, customization, reliable logistics, and full traceability. These benefits not only improve immediate procurement outcomes but also build long-term strategic value for companies engaged in tooling, die-casting, and manufacturing industries.

For procurement managers, wholesalers, and distributors navigating today’s competitive environment, the case for direct engagement with steel factories has never been stronger. By forging closer ties with the source of production, businesses secure not only better pricing but also a more resilient, transparent, and technically informed supply chain—a combination that drives sustained success in global markets.