Our Blog

How To Specify The Delivery Status Of 1.2344 Tool Steel For Subsequent Mechanical Processing?

Ever wonder why your 1.2344 tool steel sometimes machines like butter while other times it destroys tooling? The difference comes down to delivery condition. It’s not just hardness numbers—it’s how the steel was processed before it reached your shop floor. Standard...

Technical Guide To Skd61 Tool Steel: Chemical composition,Properties & Industrial Use

Ever wondered why some die-casting molds last 500,000 cycles while others crack after 50,000? SKD61 tool steel—also called H13 or 1.2344—explains this performance gap. This special alloy handles hot-work tooling better than most. It resists thermal shock that destroys...

Why SKD61 Steel Is Popular Among Korean Factories: Cost, Performance & Stability

Introduction SKD61 steel is popular in Korea for a simple reason—it delivers strong performance without high costs. After years of supplying Korean die-casting and forging shops, we’ve seen how SKD61 helps factories cut tooling cost per part, extend die life, and keep...

A2 Tool Steel Market Insights In Turkey: Opportunities For Regional Buyers

Turkish manufacturers keep picking A2 tool steel for their toughest jobs. There's a reason.This air-hardening material gives you reliable toughness and size stability. You don't pay the high cost of premium alloy options. Auto plants use it for stamping dies. Mold...

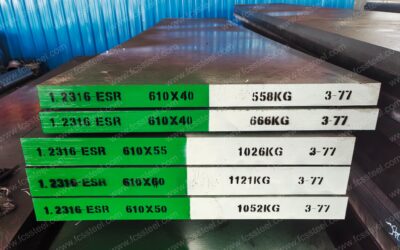

What is 1.2316 Tool Steel?

When manufacturers ask me which mold steel offers stable hardness, reliable corrosion resistance, and high polishability for chemically aggressive plastics, 1.2316 tool steel is always on the shortlist. As an engineer who has worked with hot-work and plastic-mold tool...

Skd61 Steel Wholesale Prices in Global Market & Buying Guide

SKD61—Japan’s JIS hot-work tool steel equivalent to H13 (AISI) tool steel and 1.2344 (DIN) tool steel—remains one of the most widely used die-steel grades for aluminum die-casting, extrusion dies, hot forging, and high-temperature tooling. As global manufacturing...

Customized Skd61 Steel Solutions For Non-Standard Sizes, Blocks & Precision Finishing

SKD61 steel customization goes beyond standard catalog sizes. Modern manufacturing needs non-standard dimensions, special surface treatments, and tight tolerances. Off-the-shelf products can't deliver these. You might be making detailed aluminum extrusion molds. Or...

SKD61 vs SKD11: What’s the Difference? Full Comparison Guide

Overview – SKD61 vs SKD11SKD61 and SKD11 are two different tool steel types. Each one works best under different conditions.SKD61 is a hot-work tool steel (same as AISI H13). This steel handles thermal shock well. It stays tough even after repeated heating and cooling...

Which is the best SKD61 Steel Manufacture in China

Introduction SKD61 remains one of the most widely used hot-work tool steels in the global market. Its demand is steady across die casting, forging, extrusion, and precision tooling. Today, more buyers are choosing Chinese mills because of faster delivery, lower costs,...

Get In Touch

Address

128 Zhangzhihe Avenue,Hekou Town,Xisai District,Huangshi city,Hubei Province,China