Is your production line stalled waiting for steel? Every hour of downtime bleeds profit in the mold industry. Traditional suppliers often rely on slow “just-in-time” models. This leaves you scrambling when urgent orders hit. FCS Steel Factory changes the game.

We maintain over 2,000 tons of premium tool steel ready for immediate dispatch. Forget 6-8 week lead times or forecasting errors. With FCS, you get the material you need now. This cuts downtime costs and gives you the agility to seize urgent projects your competitors simply can’t handle.

1. The Real Gap: Production vs. Prediction

Traditional JIT lacks the buffer needed for today’s unpredictable marketWhen statistical errors hit 20-50%, you face crippling stockouts or 8-week delays. FCS eliminates this risk. We replace manual audits with massive, ready-to-ship reserves, converting supplier uncertainty into your guaranteed competitive speed.

| Comparison Factor | FCS Tool Steel Factory | Traditional Tool Steel Suppliers |

|---|---|---|

| Inventory Model | Large ready-to-ship stock | Just-in-Time (JIT), forecast-based |

| Regular Stock Volume | 2,000+ tons available | Limited or project-based |

| Annual Production Capacity | 25,000 metric tons | Often outsourced or fragmented |

| Typical Lead Time | 3–8 business days(stock) | 6–8 weeks or longer |

| Urgent Order Capability | High – stock-based fulfillment | Low – production rescheduling required |

| Downtime Risk | Minimal | High during demand spikes |

| Supply Chain Stability | Factory-direct, integrated | Multi-layer distributors |

2. Inside the System: 25,000-Ton Capacity

FCS operates at a scale that changes supply chain dynamics. Our 43,000-square-meter facility isn’t just a warehouse—it’s a full production engine built for instant availability.

Core Manufacturing Power

- Consistent Output: We produce extensive tons monthly across separate lines to keep stock levels steady.

- Premium Purity: 12-ton EF+LF+VD furnaces and 6 ESR furnaces ensure every bar meets high-grade standards.

- Industrial Scale: 3-ton and 6-ton hammers process everything from small rounds to massive 500mm-thick plates.

- Batch Consistency: Two 120-ton annealing furnaces ensure uniform properties across every shipment.

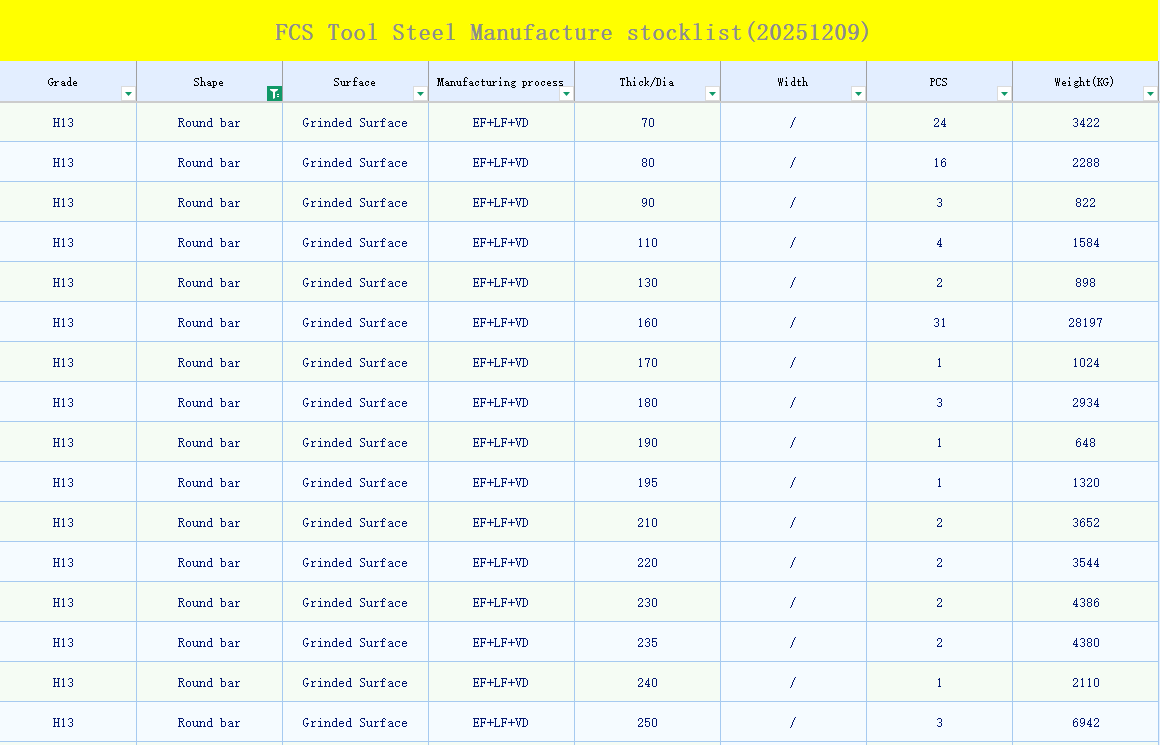

Always-Ready Grades

Our inventory focuses on high-demand tool steels. You get verified large stock availability:

1.2379/D2/X155CrVMo12-1 steel stocks run deep across multiple formats:

– Hot forged plates: 50-500mm thickness × 50-1500mm width × 3000-5800mm length

– Turned/machined surfaces: Precision cuts within 0-+2mm thickness, 0-+5/+10mm width

– Tested properties:Our uniform carbide distribution ensures a consistent compressive strength of 2200 MPa after heat treatment to 60 HRC.

XW-5 (D6/SKD2/1.2436) steel covers all dimensions you need:

– Round bars: 10-65mm hot rolled, 70-700mm hot forged diameters

– Plate stock: 10-400mm hot rolled, 50-500mm hot forged thicknesses

– Stays stable under heat: 194 GPa elastic modulus (20°C), 173 GPa (400°C)

Precision Processing Infrastructure

Precision Processing: Ten high-precision saws and plate milling machines deliver custom cuts. We use precision calipers to ensure 0/+2mm sawing tolerances, and micrometers for rigorous internal quality verification of material thickness and consistency.our adaptive nesting system ensures maximum material utilization, reducing unnecessary waste on expensive alloys.

Verified Quality: Every batch undergoes ultrasonic testing (SEP 1921-84 Class 3).

3. Cost Efficiency: Factory-Direct Value

Factory-direct pricing meets instant availability. We cut the two biggest drains in tool steel procurement: middleman markups and delay penalties.

Traditional chains add 15-30% margins at every stop—from mill, to importer, to distributor. We cut that chain. Our 25,000-ton capacity feeds directly into warehouse stock. You buy at manufacturer prices, shipping from existing inventory, not future promises.

Eliminate Hidden “Waiting Costs”

A typical 6-8 week lead time costs you more than just time:

- Inventory Costs: You’re forced to hoard buffer material.

- Idle Production: Teams wait; machinery sits silent.

- Lost Opportunities: You can’t accept rush orders.

This comparison shows its clearest advantage here. Our stock covers the most-demanded grades with verified depth:

| Category | Equivalent Grades (ASTM / DIN / JIS) | Formats Available |

| Cold Work Steel | D2, 1.2379, SKD11, A2, D3, D6, O1 | Plates & Round Bars |

| Hot Work Steel | H13, 1.2344, SKD61, H11, H21 | Plates & Round Bars |

| Plastic Mold Steel | S136, 1.2083, 1.2316 | Precision Cut Blocks |

| Specialty & Others | L6, S7, European 1.2xxx series | Various Formats |

Multi-Standard & Risk-Free

Our stock meets ASTM, DIN, and JIS standards simultaneously. Need to validate? Don’t wait months. Order trial quantities from stock, 48-hour dispatch from warehouse, with express air-freight options targeting delivery within 10 business days, and verify with your own labs. Direct factory rates + no delay costs = 30-40% lower total acquisition cost.

Factory-direct pricing + zero-downtime reliability = Significant reduction in Total Cost of Ownership (TCO).

4. Risk Mitigation Through Inventory Depth

No stock stops production lines. Excess stock ties up capital. FCS Steel’s inventory depth resolves this trade-off. Our ready stock acts as a buffer against demand volatility that traditional “Just-in-Time” models often fail to cover. While other suppliers struggle with market fluctuations, our consistent annual capacity ensures deep reserves of high-demand grades.

We eliminate the risk of data lag. Instead of relying on weekly manual audits that lead to “surprise” shortages, we track inventory in real-time. This factory-direct availability bypasses middleman vulnerabilities. When global supply chains face port delays or disruptions, our physical stock remains accessible immediately. This protects your operation from the $500-2,000 hourly cost of idle machinery.

5. Key Industry Applications: Why Stock Depth Matters

Automotive (JIT Demand):

Automotive manufacturers run just-in-time systems. A single mold delay stops assembly lines. Those lines produce thousands of vehicles each day. Lightweight component molds need high-precision tool steels. These steels maintain shape stability through millions of cycles.

Electronics (Rapid Switching):

Electronics mold manufacturing runs small batches across dozens of component types. Automation lines need quick material access for high-speed production. A stockout on precision-grade steel stops the entire schedule.

Packaging (High Volume):

This market holds 32.2% revenue share. Mass production runs at extreme speeds. A single material shortage cascades into millions of lost units.Use our capacity as insurance against costly downtime.

Medical (Compliance):

Precision syringes, surgical devices, and diagnostic equipment need special materials. These materials must have strict compliance documentation. We provide ISO9001/SGS certified stock. You get full traceability, which ensures cleanroom validation.

FCS Inventory Solution Matrix

| Industry | Core Stock Grades | Key Stock Advantage |

|---|---|---|

| Automotive | 1.2344 (H13), 1.2379 (D2), H11 steel | Large plates (50-500mm) are ready. Start heavy-duty forging immediately. |

| Electronics | D2, D6, S136 steel, Pre-hardened | Get custom precision cuts (< 2mm tolerance) |

| Packaging | S136, 1.2083, 1.2316 steel | We stock bulk corrosion-resistant grades. Great for emergency refills. |

6. Service Evolution: How Stock Readiness Builds Partnerships

1. Immediate Speed: Standard orders ship within 3-5 business days. Common blocks leave regional warehouses in 48 hours, skipping the typical 6-8 week wait.

2. Reliable Quality: Rejection rates stay below 0.8%, verified by third-party audits. This consistency beats the 3-5% industry average, preventing project rework.

3. Process Flexibility: We stock multiple conditions—annealed, pre-hardened, and ground bars—so you can choose the material state that fits your machining workflow.

4. Direct Communication: You talk to factory engineers, not middlemen. Technical questions and quotes get answered within 24 hours.

5. Global Compliance: Our inventory meets ASTM, DIN, and JIS standards simultaneously. Every shipment includes ISO9001/SGS documentation.

6. Cost Control: Buying factory-direct eliminates distribution markups and rush fees, reducing your total material costs by 18-25% annually.

Conclusion

The steel business has changed. Traditional suppliers often keep you waiting weeks. FCS Steel’s 2,000-ton ready stock system ends those delays. We turn inventory into your advantage. You get premium grades right when you need them, not months later. You finish faster and lower your total costs. This is your new reality.

Material shortages shouldn’t stop your production line. Ready to secure your supply chain? Contact FCS Steel today. Check stock availability and get your quote fast.