The right tool steel makes or breaks your plastic molding operation. This matters most with corrosive materials like PVC, flame retardants, or moisture-rich polymers.Standard tool steels fail fast. They pit and degrade at the surface. But 1.2316 tool steel is different. It resists corrosion better than most options. Manufacturers choose it for harsh processing conditions.

This martensitic stainless steel gives you three key benefits. You get corrosion protection, mechanical strength, and mirror-polishing ability. These qualities turn tough mold projects into reliable production tools.

Chemical Mix Explained

Chromium makes 1.2316’s formula special. This steel contains 15.5–17.5% chromium. That’s far above the 10.5–12% needed for true stainless properties. The extra chromium builds a dense, self-healing shield on the metal surface.

1.2316 Steel: Chemical Defense Mechanism

| Element | Content (%) | Core Function & Mechanism |

| Chromium (Cr) | 15.5–17.5 | Forms a self-healing Cr2O3 passive film; provides 10x more corrosion protection than standard steels. |

| Molybdenum (Mo) | 1.00–1.30 | Enriches the protective layer to prevent pitting corrosion from chlorides (PVC/cooling water). |

| Manganese (Mn) | 1.00–1.30 | Binds sulfur to prevent large sulfide stringers, removing potential corrosion initiation sites. |

Note: This 16% Cr + 1% Mo combination provides roughly 10x the corrosion resistance of standard 1.2083 steel.

2. 1.2316 Tool Steel Beats Corrosion in Tough Plastic Processing

In the harsh environment of plastic molding, standard steels fail where 1.2316 excels. Here is how its properties directly tackle the industry’s toughest challenges:

1. The Acid Challenge: PVC & Halogen Outgassing

Condition: At 180–220°C, PVC breaks down to release hydrochloric acid vapors and chlorine that aggressively pit standard mold cavities.

1.2316 Solution: Its 16% Chromium + Molybdenum matrix builds a superior chemical shield, significantly outperforming legacy 1.2083 steel against chloride attack.

2. The Additive Attack: Flame Retardants & Chemical Stabilizers

Condition: Aggressive additives—like flame retardants and organic acids—concentrate on hot mold surfaces, attacking weak grain boundaries.

1.2316 Solution: The uniform pre-hardened structure of 280–325 HB (approx. 30–35 HRC) provides consistent resistance across the entire block, eliminating the “soft spots” where corrosion starts in heat-treated steels.

3. The Hygiene Demand: Repeated Medical Sterilization

Condition: Medical molds must survive daily exposure to harsh, acidic sanitizers and aggressive cleaning agents without degrading.

1.2316 Solution: It maintains a high-purity, FDA-compliant mirror finish that resists chemical etching, ensuring dimensional accuracy stays intact despite frequent cleaning.

4. The Hidden Threat: High-Humidity Cooling Systems

Condition: Warm, moist cooling channels (40–60°C) typically rust from the inside out, restricting water flow and risking part contamination.

1.2316 Solution: A dense chromium oxide passive film coats internal water lines and manifolds, preventing rust buildup even in 90% humidity environments.

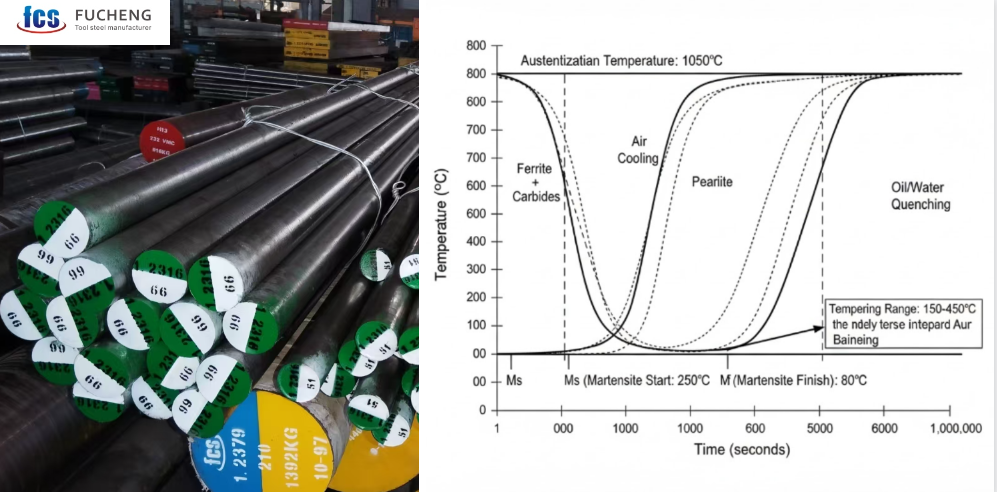

3. Optimal Hardness: Picking the Right State

Pick the right hardness. Your 1.2316 mold performs better. You generally have two paths: Pre-hardened for stability or Heat-Treated for durability.

Pre-Hardened: The Production Workhorse

Range: 280–325 HB (approx. 30–35 HRC)

This is the “ready-to-go” state. It hits the sweet spot for 90% of jobs.

- Stability: Huge advantage for large molds (>410mm). You avoid the warping and size changes that happen during heat treatment.

- Cost & Speed: Skip the quenching step. Machine it, polish it, and run it.

- Performance: Strong enough for PVC, Cellulose Acetate (CA), and standard acidic polymers.

Heat-Treated: Maximum Wear Protection

Range: 400–470 HB (42–49 HRC)

Need to run glass-filled polymers or high-volume die casting? You need to quench and temper. This range doubles or triples tool life in abrasive conditions but requires careful machining allowances for distortion.

Quick Decision Guide

|

Choose Pre-hardened 280–325 HB (~30–35 HRC) |

Choose Heat-Treated 42–49 HRC |

| ✅ Large complex molds (risk of warping) | ✅ High-volume precision parts |

| ✅ Corrosive plastics (PVC) | ✅ Abrasive fillers (Glass/Mineral) |

| ✅ Medium production runs | ✅ Aluminum or magnesium die-casting |

| ✅ Mirror-finish surfaces | ✅ Mechanical forging or stamping dies |

4. Wear Resistance for High-Volume Production

1.2316 fights wear using hard chromium-molybdenum carbides. In its pre-hardened state of 280–325 HB (approx. 30–35 HRC), it acts as a reliable workhorse for standard thermoplastics. Clean resins like polypropylene slide easily across the surface without galling.

However, know the limits. For glass-filled plastics, this steel is too soft. You are better off using heat-treated 1.2083 tool steel at 50–54 HRC to withstand that abrasive cutting action.

Compare this to standard P20 or 718 tool steel. 1.2316 gives you better density. You get strong wear protection for complex molds. Choose this for high-volume jobs that are corrosive, not abrasive.

The strength of 1.2316 lies in its resistance to chemical corrosion, rather than its extreme resistance to wear.

5. Mirror Polishing Capability for High-Precision Molds

Optical components and high-gloss parts demand perfection. 1.2316 delivers true mirror capability (Ra < 0.1 μm) thanks to its superior cleanliness. It outperforms standard S-136 tool steel by maintaining a crack-free surface even in corrosive conditions.

The Hidden Challenge: Microstructure

Standard grades often fail here. They mix soft zones with hard carbides. The soft parts polish faster, creating “orange peel” waves. To avoid this, material quality is non-negotiable.

3 Steps to Flawless Results

guarantee optical quality without wasting time:

- Specify ESR: Always use Electroslag Remelted (ESR) steel for optical parts. It removes sulfur inclusions that tear out and ruin the surface.

- Control Pressure: Go easy. High pressure with diamond paste pulls carbides out, scratching the mirror.

- Stay Pre-Hardened: Polishing at 30–36 HRC is the sweet spot. You get a crisp finish without the distortion risks of heat treating.

ESR (electroslag remelting) is a necessary condition for 1.2316 to achieve mirror-level polishing.

6. Why 1.2316 Tool Steel Works Better for Alloy Dies

Heat plus corrosion creates trouble for standard hot-work steels like H13. 1.2316 steps in to fill that gap. It gives you distinct advantages for alloy die casting and stamping:

1. The Heat Challenge: Aluminum & Zinc Die Casting

Condition: Molten alloys at 600–700°C attack die surfaces. This leads to “soldering” and heat checking.

1.2316 Solution: High chromium content cuts down soldering. The steel resists thermal shock thanks to its pre-hardened toughness of 300–340 HB (approx. 32–36 HRC). You get 20–30% longer die life compared to standard steels.

2. The Stamping Struggle: Forming Stainless & Copper

Condition: Stamping abrasive sheets causes galling (material adhesion). You often see edge chipping. Standard cold-work dies turn brittle too easily.

1.2316 Solution: A uniform carbide structure stops adhesive wear. It holds a sharp cutting edge unlike brittle high-carbon steels. It prevents micro-chipping even during high-impact cycles.

3. The Environment Factor: Coastal & Humid Plants

Condition: High humidity and salty air are harsh environments. Standard H13 has 5% Cr and rusts during storage or downtime.

1.2316 Solution: This grade packs 16% Chromium. It functions as true stainless steel. Humid air or aggressive release agents cannot cause corrosion. Your dies stay ready-to-run, so you skip the extra polishing.

4. The Finish Requirement: Mirror-Quality Alloy Parts

Condition: Corrosive fluxes and condensates etch the die surface. This destroys the finish on precision alloy parts.

1.2316 Solution: A dense oxide surface layer blocks chemical etching. It maintains a Ra ≤ 0.05 μm mirror finish. Parts release clean, even after thousands of shots.

1.2316 is mainly used in die casting for mold frames, slides, or cooling components, or for die casting of highly corrosive zinc alloys. For aluminum die casting mold cores, H13 or 1.2367 remain the preferred choices.

7. Proven ROI: 1.2316 vs. Standard Steels

Theory is good. Results are better. We tracked mold performance across different industries. Here is how switching to 1.2316 changes your maintenance schedules and tool life:

| Application | Standard Steel (1.2311/P20) | 1.2316 Performance | The Gain |

|---|---|---|---|

| Medical PVC Tubing | Micro-pitting appears after 4 weeks due to HCL gas. | Zero surface degradation after 6 months of continuous running. | 6x Longer Service Interval |

| Cosmetic Caps (High Gloss) | Mirror finish clouds up; needs repolishing every 50,000 shots. | Retains Ra < 0.05μm shine for 200,000+ shots. | 75% Less Polishing Downtime |

| Automotive (Flame Retardants) | Gas burns and corrosion clog vents weekly. | Vents stay clear; uniform hardness resists gas erosion. | Consistent Cycle Times |

| Coastal Molding Plant | Cooling channels rust during weekend shutdowns. | Channels stay rust-free indefinitely. | Zero Flow Restriction |

Conclusion

In high-volume PVC or medical molding, the real cost isn’t the steel—it is the downtime. Standard grades degrade quickly against aggressive resins, but 1.2316 eliminates this bottleneck.

With its 16% Chromium shield, it stops pitting and keeps cooling channels rust-free. You get consistent cycle times and mirror finishes that last millions of shots. For corrosive environments, 1.2316 isn’t just an upgrade; it is the essential baseline for reliable production.