1.2344 steel (also known as H13 in ASTM standard) is a widely used hot-work tool steel, applied in die casting, extrusion, forging, and high-temperature tooling. For buyers, especially those sourcing in international markets, procurement goes far beyond negotiating a price. Precision in technical requirements, supplier clauses, and inspection routines determines whether the steel performs as expected or becomes a costly liability.

This article provides a practical procurement checklist for 1.2344 steel buyers, covering chemical specs, heat treatment, hardness verification, inspection certificates, packaging, and supplier contract clauses.

1. Defining Material Specifications Clearly

1.1 Chemical Composition Tolerances

1.2344 steel typically contains:

- C: 0.38–0.42%

- Si: 0.8–1.2%

- Mn: 0.25–0.5%

- Cr: 4.8–5.5%

- Mo: 1.2–1.5%

- V: 0.85–1.2%

👉 In contracts, buyers should set explicit chemical tolerance ranges. For example, instead of accepting a generic “Cr ~ 5%,” specify “Cr: 4.9–5.3%” to ensure stability in hot fatigue resistance.

1.2 International Equivalents

- DIN EN: 1.2344

- ASTM: H13

- JIS: SKD61

- GB: 4Cr5MoSiV1

Including equivalents in contracts helps cross-check supplier claims and avoids substitution with lower grades.

2. Heat Treatment Routes and Performance Guarantees

Heat treatment determines the service life of 1.2344 steel tools. Buyers should request suppliers to provide heat treatment routes as part of COA (Certificate of Analysis).

2.1 Standard Heat Treatment Parameters

- Preheating: 600–650 °C, second stage 850–900 °C

- Austenitizing: 1000–1040 °C

- Quenching: air or oil, depending on section size

- Tempering: 3 cycles, 540–620 °C

2.2 Contractual Clauses

- Supplier must document exact furnace curves used.

- Specify hardness ranges post-heat treatment (e.g., HRC 44–48 for die-casting applications).

- Require confirmation of tempering stability, verified by secondary hardness tests.

3. Hardness, Microstructure, and Nondestructive Testing

3.1 Mechanical Property Requirements

- Hardness after delivery: typically 229–285 HB (annealed condition).

- After hardening and tempering: 44–52 HRC depending on application.

3.2 Inspection Checklist

- Hardness test (Brinell or Rockwell) report.

- Ultrasonic Testing (UT) according to EN 10228-3 Class 3.

- Microstructure verification: inclusion rating, carbides distribution, grain size ASTM 5–8.

3.3 Sample Data (Reference)

| Property | Requirement | Verification Method |

|---|---|---|

| Hardness (annealed) | 229–285 HB | Brinell test |

| Hardness (after HT) | 44–48 HRC | Rockwell C |

| Microstructure | Uniform tempered martensite, carbides evenly distributed | Metallography |

| UT testing | Class 3 (no cracks, inclusions >3mm) | Ultrasonic |

4. Packaging, Anti-Rust, and Logistics Considerations

- Anti-rust protection: specify VCI (volatile corrosion inhibitor) paper wrap.

- Export packaging: seaworthy wooden boxes with desiccant bags.

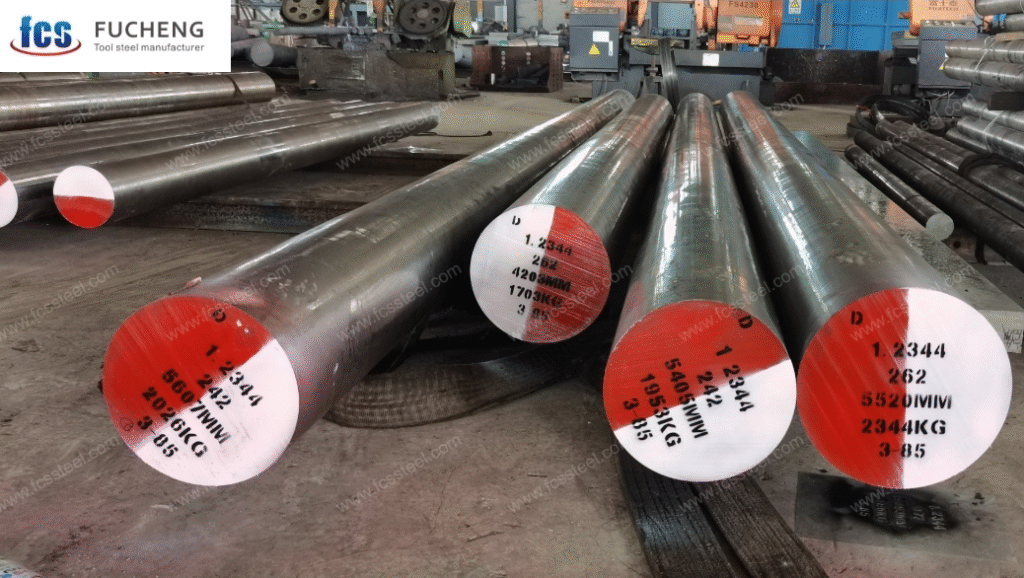

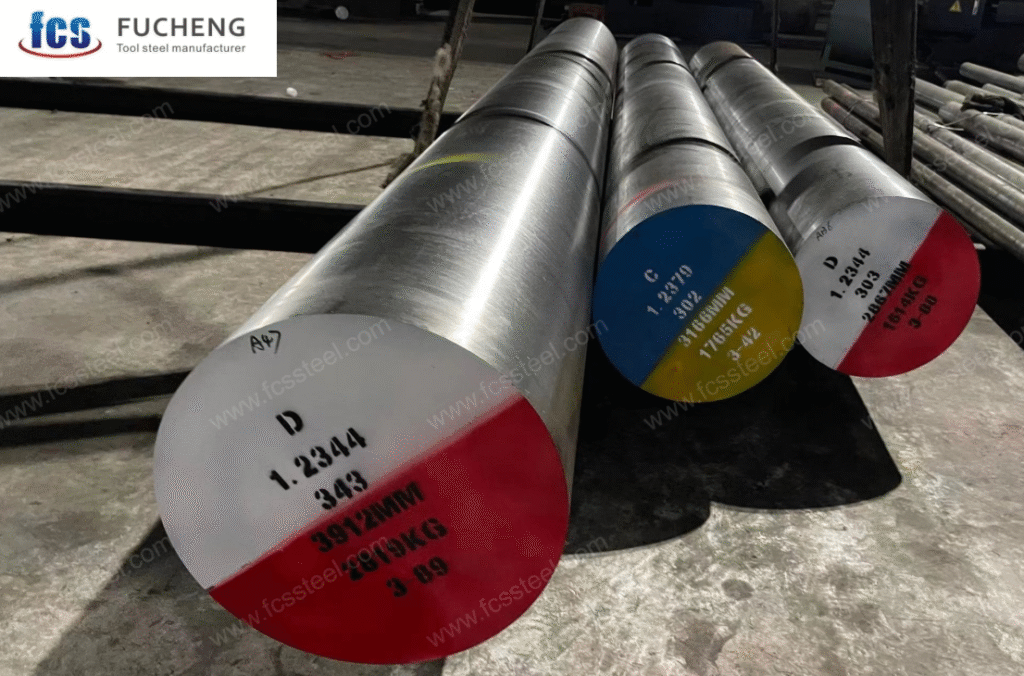

- Traceability: each steel bar should be stamped with heat number and match COA.

- Delivery terms: DDP vs FOB vs EXW — align with Incoterms 2020 to reduce disputes.

5. Supplier Contract Clauses to Safeguard Buyers

5.1 Quality Assurance Clauses

- Supplier guarantees compliance with EN ISO 4957 for hot-work tool steels.

- Non-compliant batches must be replaced or refunded within 60 days.

5.2 Warranty and Liability

- Minimum 12 months warranty against cracking due to improper processing.

- Liability coverage for machining rework if steel fails hardness/microstructure tests.

5.3 Arbitration and Jurisdiction

- Define governing law (e.g., ICC arbitration, neutral jurisdiction).

- Helps international buyers avoid local legal disadvantages.

6. Sample Procurement Checklist for Buyers

Below is a ready-to-use checklist buyers can adapt for their procurement contracts.

6.1 Documentation

- COA (Certificate of Analysis) with chemical composition.

- Hardness report (HB/HRC).

- Ultrasonic Test report.

- Metallographic photos (microstructure).

- Heat treatment furnace curves.

6.2 Technical Requirements

- Chemical composition with tolerance ranges.

- Heat treatment route defined.

- Hardness range specified.

- UT testing class defined.

- Inclusion rating ≤ 1.5 (per DIN 50602).

6.3 Logistics and Packaging

- Seaworthy packaging with anti-rust protection.

- Full traceability (heat number on each piece).

- Delivery terms aligned with Incoterms 2020.

6.4 Supplier Clauses

- Warranty period (12 months minimum).

- Replacement/refund terms.

- Arbitration clause defined.

7. Cost-Saving Procurement Actions

| Action | Potential Saving (%) | Notes |

|---|---|---|

| Consolidated orders with one supplier | 3–5% | Reduces logistics cost |

| Long-term contract vs spot buy | 5–8% | Locks in alloy surcharge risk |

| Regional sourcing (avoid tariffs) | 2–6% | Especially EU buyers vs China imports |

| Pre-shipment third-party testing | Avoids rework losses | Ensures compliance |

8. Conclusion: Turning Checklists into Procurement Strength

For 1.2344 steel buyers, procurement is not simply about comparing tonnage prices. By structuring contracts around chemical tolerances, heat treatment routes, inspection certificates, packaging, and warranty clauses, buyers reduce risks and extend tool life in demanding hot-work environments.

A well-defined procurement checklist transforms negotiations from price-driven to value-driven, ensuring both technical compliance and cost efficiency.