Japan’s manufacturing sector has long been recognized for its precision engineering, advanced material science, and commitment to quality. From automotive die manufacturing to high-performance cutting tools, Japanese industries rely heavily on a diverse range of tool steels. These materials are selected not only for their hardness and wear resistance but also for their ability to perform reliably under demanding operating conditions.

Below, we outline the 10 most commonly used tool steel grades in Japan, their key characteristics, and where they are typically applied.

SKD11 (Equivalent to D2 / 1.2379)

SKD11 is the most widely used cold work tool steel in Japan. It offers excellent wear resistance, high compressive strength, and dimensional stability after heat treatment. Commonly used for blanking dies, forming dies, and shear blades, SKD11 is an indispensable material in automotive stamping and electronics manufacturing.

SKD61 (Equivalent to H13 / 1.2344)

As a premium hot work tool steel, SKD61 has exceptional toughness and resistance to thermal fatigue. Its performance in high-temperature applications makes it the top choice for aluminum extrusion dies, die casting molds, and hot forging tools in Japan’s heavy industry sector.

SKH51 (Equivalent to M2 / 1.3343)

This high-speed steel grade is valued for its outstanding red hardness, allowing cutting tools to maintain sharpness under extreme heat. SKH51 is extensively used for drills, milling cutters, and threading tools in Japan’s machine tool manufacturing industry.

SKS3 (Equivalent to O1 / 1.2510)

A popular oil-hardening tool steel, SKS3 combines good wear resistance with excellent machinability. Japanese mold makers frequently use SKS3 for low-volume dies, gauges, and precision tools where dimensional accuracy is critical.

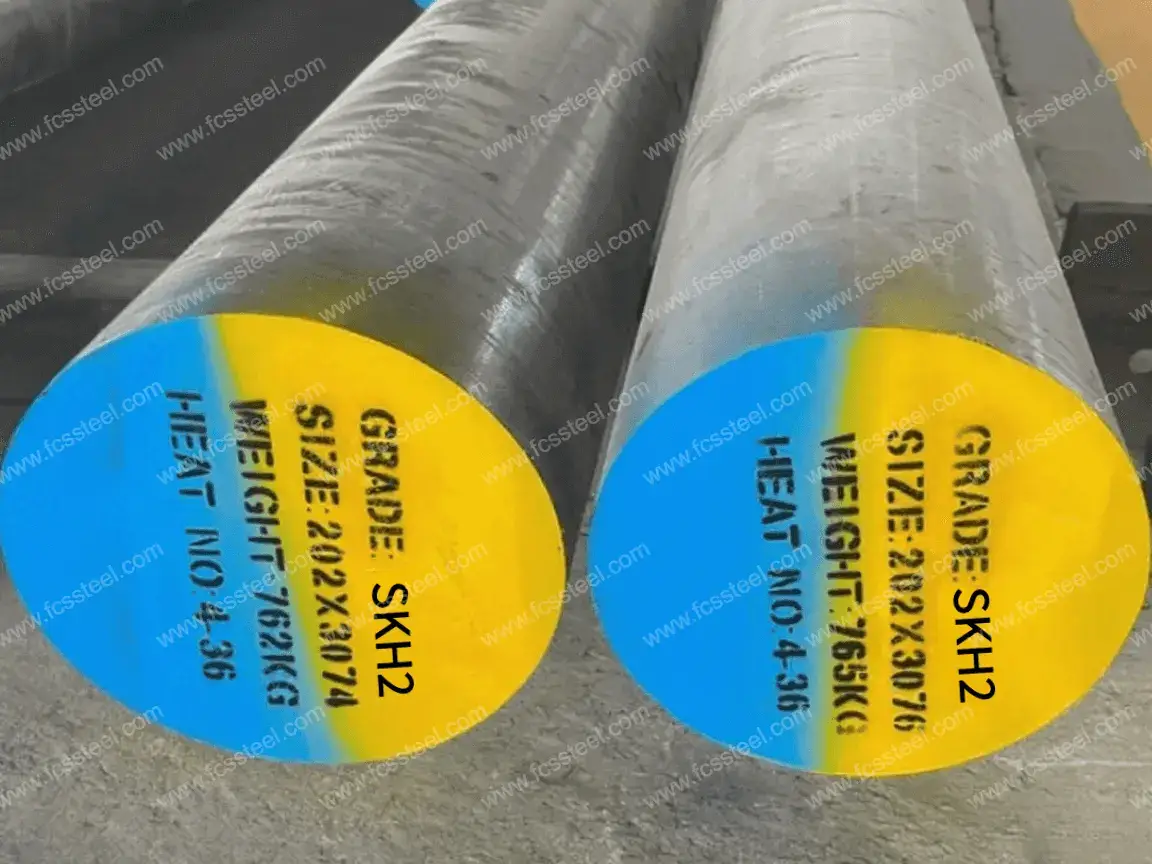

SKH2 (Equivalent to T1 / W18Cr4V)

Known for its high tungsten content, SKH2 is a high-speed steel with exceptional hardness and wear resistance. It is widely applied in Japan’s cutting tool sector, particularly for saw blades, punches, and reamers.

SKS93 (Equivalent to A2 / 1.2363)

This air-hardening cold work steel is favored for its balance between wear resistance and toughness. In Japan, SKS93 is used for blanking dies, forming rolls, and precision gauges that require stability during long production runs.

SKD12 (Modified D2)

JIS SKD12 is a modified version of SKD11, offering slightly higher toughness while maintaining wear resistance. It is a preferred choice for high-precision, high-volume stamping dies in Japan’s electronics and automotive industries.

SKH2 (Equivalent to T1 High-Speed Steel)

SKH2 offers a good balance between toughness and cutting performance, making it suitable for general-purpose cutting tools. It is particularly used in Japan for drills, end mills, and gear-cutting tools where moderate speeds are involved.

SKT4 (Shock-Resistant Tool Steel)

SKT4 is known for its exceptional impact resistance, making it suitable for tools subjected to high shock loads. In Japan, it is commonly used in chisels, hot shear blades, and forging hammers.

SKD7 (Equivalent to DC53)

An advanced cold work die steel, SKD7 offers higher toughness and fatigue resistance compared to SKD11. It is a top choice for progressive dies and complex forming tools in Japan, especially where both wear and impact resistance are required.

Why These Grades Are Market Leaders in Japan

The prevalence of these tool steels in Japan is driven by the country’s industrial structure—where precision, long service life, and cost-efficiency are key priorities. Japanese manufacturers often select tool steels not only for their mechanical performance but also for their ease of heat treatment, dimensional stability, and ability to meet strict quality standards.

FCS Tool Steel – Your Trusted Partner for Japanese-Grade Tool Steels

From my experience, FCS Tool Steel is a top supplier if you need Japanese-grade tool steels. They focus on popular JIS-equivalent grades like SKD11, SKD61, and SKH51. Their product line has the most widely used tool steels in Japan. This assures me that I’m getting materials that meet the strict Japanese Industrial Standards (JIS).

Reliable Supply of Japanese-Grade Tool Steels

- Wide Range of Grades: I like that FCS offers premium tool steels such as SKD11 (D2 equivalent) and SKD61 (H13 equivalent). They also carry SKH51 (M2 equivalent) and more. Every product is made to match Japanese standards.

- Large Inventories: They keep a large amount of stock on hand. This practice lets them fill bulk orders and urgent requests quickly.

- Strict Quality Assurance: Every batch of steel goes through tough quality checks. For your peace of mind, they make the testing data available so you can see the results.

Global Shipping and Technical Support

- Worldwide Delivery: FCS has a global shipping system. They get Japanese-grade tool steels to manufacturers and engineering companies all over the world, and they do it fast.

- Expert Support: I suggest talking to their professional team. They will help you choose the best steel grade for your project. Their advice can improve your productivity and help lower your costs.

Why Choose FCS Tool Steel for Japanese-Standard Steels?

- Consistent Quality: I choose FCS because their quality is dependable. Each tool steel product meets the high standards required for tough industries. This includes automotive, electronics, and precision manufacturing.

- Efficient Sourcing: You can get all your JIS tool steel grades from one place. This saves me time and makes the entire buying process much simpler.

- Trusted by Global Manufacturers: I believe their strict inspection process, fair pricing, and expert knowledge make them a great partner. Many businesses choose them when they need reliable Japanese-grade tool steel.