W6Mo5Cr4V2 Tool Steel

W6Mo5Cr4V2 has stable heat treatment performance and is suitable for high-temperature and high-speed cutting environments.

W6Mo5Cr4V2 Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

W18Cr4V Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

W6Mo5Cr4V2 Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

W18Cr4V Tool Steel – Product Forms & Inventory Specifications

Supply Condition

- Annealed

- Machined

Available Forms

- Round bars

- Plates / Flat bars

- Custom-cut pieces

Processing Services

- Sawing.

- Rough machining.

- Custom heat treatment.

Standard Size Range (Availability varies by stock)

- Diameter (Round bar): Φ10 mm – Φ65 mm / Φ70 mm – Φ400 mm / Φ500 mm / Φ600 mm / Φ700 mm.

- Plate/Flat Thickness: 8 – 45 mm / 50 – 500 mm.

- Width: 50 – 1000 mm / 50 – 1500 mm.

- Forged Discs: Up to Ø1200 mm.

W6Mo5Cr4V2 Tool Steel – Forming Methods

- Hot Rolled

- Hot Forged

W6Mo5Cr4V2 Tool Steel – Surface Finish Options

- Black.

- Grinded.

- Sandblasted.

- Turned/Machined/Milled/Bright.

What is W6Mo5Cr4V2 Tool Steel?

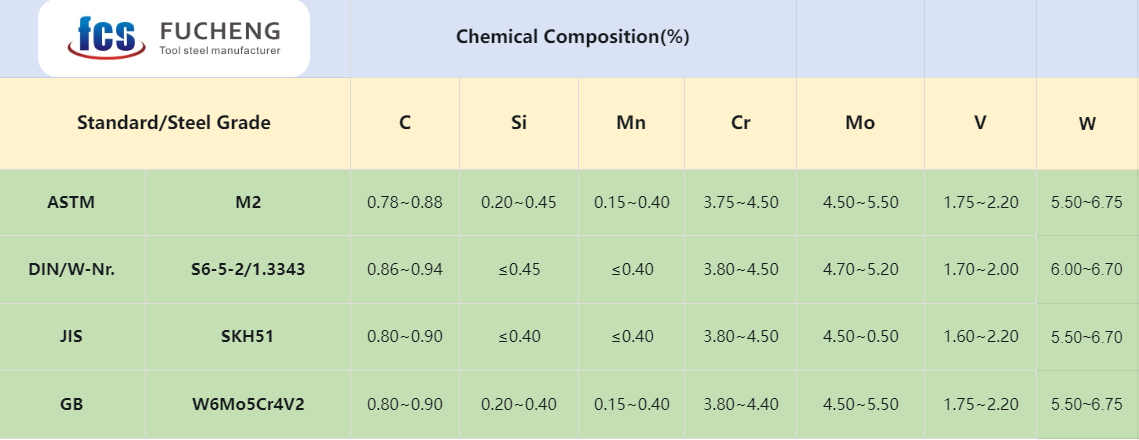

W6Mo5Cr4V2 (commonly known as M2 or high-speed steel) is a typical tungsten-molybdenum high-speed tool steel, containing approximately 5.50-6.75% tungsten, 4.50-5.50% molybdenum, 3.8-4.40% chromium, and 1.75-2.20% vanadium. This material features a combination of high red hardness, outstanding wear resistance and excellent toughness, making it one of the preferred steel grades for manufacturing high-performance cutting tools such as taps, milling cutters, drills and gear cutters.

International Equivalent Grades of W6Mo5Cr4V2 Tool Steel

Chemical Composition of W6Mo5Cr4V2 Tool Steel

W6Mo5Cr4V2 Steel Product Specifications

W6Mo5Cr4V2 Tool Steel:Heat treatment process

- Annealing: Preheat to approximately 870 °C, cool slowly to 538 °C (1000°F), then air cool. The hardness should be controlled below 255 HBW, which can be used for mechanical processing preparation.

- Quenching: 1216 °C salt bath or in a protected environment heat for 5-15 minutes and then oil cool; The hardness can reach ≥ 65 HRC.

- Tempering: It is recommended to temper in the range of 540-564 ° C. Three treatments can stabilize the final hardness at ≥ 65 HRC while maintaining excellent red hardness.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |