420SS Tool Steel | 1.2083 | X42Cr13

Premium grade 420SS,, 1.2083, X42Cr13 plastic tool steels offer excellent hardness, corrosion resistance and dimensional stability. Suitable for plastic moulds, cutting tools, surgical instruments and high wear parts in harsh environments.

420SS Tool Steel | 1.2083 | X42Cr13 Product Introduction

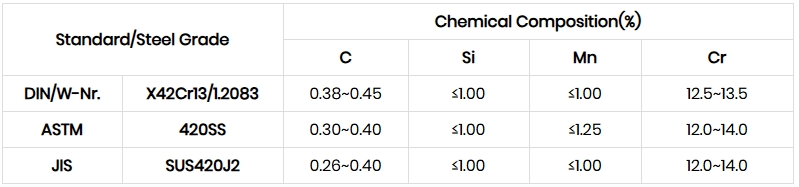

All three are 13% chromium martensitic stainless steels, relying on chromium carbide strengthening to achieve high hardness and corrosion resistance, but 1.2083 has higher purity and organisational homogeneity due to the ESU process, while 420SS has a wide carbon range (0.30-0.40%) that may affect hardness stability.

420SS tool steel (AISI/ASTM standard)

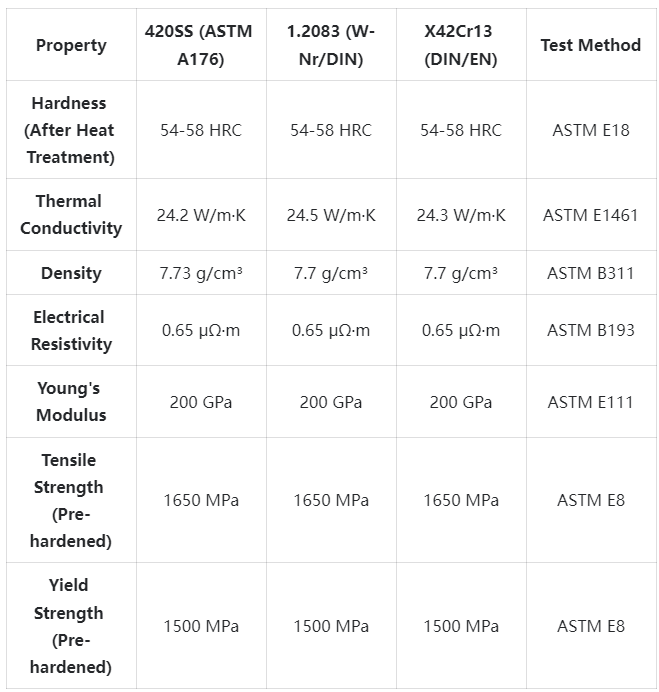

420SS tool steel is a martensitic stainless steel (corresponding to the national standard 4Cr13, the implementation of the standard GB/T 1220-1992), with a core composition of 0.30-0.40% carbon and 12.00-14.00% chromium. Its characteristics include high hardness (hardness ≥50 HV after quenching) and oxidation resistance (can be used for a long time at 600-650 ℃), but the forging needs to be preheated to control the risk of cracking (preheating 650-750 ℃, the final forging temperature of > 800-850 ℃). Heat treatment requires oil-cooled quenching at 1050-1100°C and fast-cooled tempering at 200-300°C. The hardness in the annealed condition is ≤225 HBS, and the metallurgical organisation is typical martensite.

1.2083 tool steel (W-Nr/DIN standard)

1.2083 tool steel is a high-purity electroslag remelted (ESU) chromium steel (DIN standard) with a strictly controlled composition of 0.38-0.45% carbon, 12.5-13.5% chromium, and very low sulphur and phosphorus impurities (S≤0.002%). Its core strengths are a fine uniform microstructure and low deformation, a hardness of 56 HRC after quenching in oil/gas at 1020-1050°C and tempering at 160-300°C, as well as excellent polishability (for a high surface finish) and thermal stress fatigue resistance, with an annealed hardness of ≤225 HBS.

X42Cr13 tool steel (EN/DIN/W-Nr standard)

X42Cr13 tool steel is a high-carbon, high-chromium martensitic stainless steel (composition: 0.38-0.45% carbon, 12.50-13.50% chromium) with a high degree of overlap with the composition of 1.2083 but with a narrower carbon range. Characteristics of the emphasis on high hardenability and dimensional stability, factory for the annealed state (hardness 215-225 HBS), quenched and tempered to balance the hardness and toughness; its magnetic and oxidation resistance (mild environment) is outstanding, but the welding needs to be pre-cooled anti-cracking.

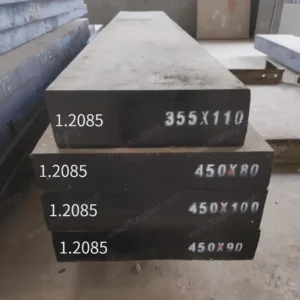

420SS Tool Steel | 1.2083 | X42Cr13 Types and Options

The table below shows the size range, surface condition and tolerance details for 420SS/1.2083/X42Cr13 Tool Steel:

420SS Tool Steel | 1.2083 | X42Cr13 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 420SS/1.2083/X42Cr13 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

420SS Tool Steel | 1.2083 | X42Cr13 Chemical Composition

420SS Tool Steel | 1.2083 | X42Cr13 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

420SS Tool Steel | 1.2083 | X42Cr13 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

420SS Tool Steel | 1.2083 | X42Cr13 Technical Specifications

420SS Tool Steel | 1.2083 | X42Cr13 Product Applications

High performance cutting tools

Our T1 tool steel excels in metal cutting applications where tools must maintain a sharp edge at high temperatures and pressures. Cutting tools made from our premium T1 tool steel last 40-60% longer when machining difficult-to-machine materials such as Inconel, titanium alloys and hardened steels. The high tungsten content creates a stable carbide that resists softening, even at cutting edge temperatures of 500-600°C in continuous high-speed machining operations.

Cold work punches and dies

The superior wear resistance of our T1 tool steel makes it ideal for stamping, dropping and forming operations involving abrasive or high-strength materials. Manufacturers report 3-5 times longer tool life when using our precision-ground T1 tool steel to produce complex shapes for electrical laminations and thick structural parts. The combination of high hardness and sufficient toughness prevents progressive wear and catastrophic failure.

Hot Work Applications

Unlike many tool steels that lose their hardness at elevated temperatures, our T1 grade maintains its mechanical properties when subjected to heat for extended periods of time. Moulds and forming tools made from our vacuum heat-treated T1 steels excel in operations such as hot forging, hot extrusion and hot stamping of high-strength steels. The stability of tungsten carbides at high temperatures prevents premature tool failure and dimensional changes during operation.

Precision Measuring and Gauging Tools

The dimensional stability and wear resistance of T1 tool steel make it ideal for precision measuring instruments and gauging tools. Our specially treated T1 material is subjected to multiple stress relieving cycles and deep cooling to ensure minimal dimensional change over time. Quality control laboratories and inspection departments rely on our T1 steel for reference gauges and measuring fixtures where long-term dimensional accuracy is critical.

Wood and paper cutting tools

The excellent edge retention of T1 tool steel makes it particularly valuable when processing highly abrasive materials such as fibre-reinforced wood products, laminates and speciality papers. Planer knives, slitting blades and circular saw blades made from our T1 steel cut these materials with 2-3 times longer service intervals between resharpening, significantly reducing downtime and resharpening costs.

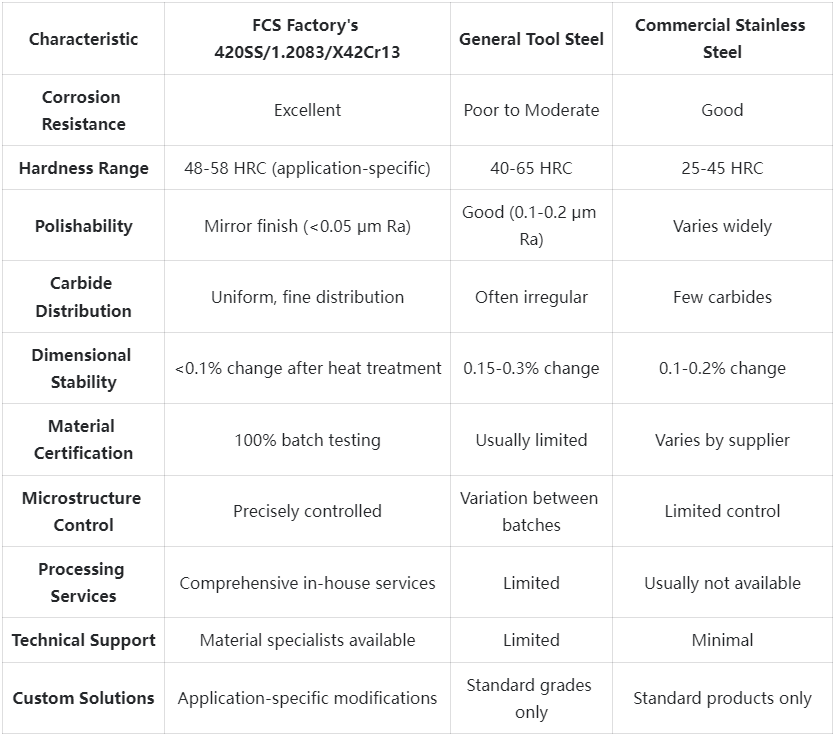

420SS Tool Steel | 1.2083 | X42Cr13 Competitive Advantage Comparison

420SS Tool Steel | 1.2083 | X42Cr13 Customer Success Stories

420SS Tool Steel | 1.2083 | X42Cr13 Pricing Structure Information

420SS Tool Steel | 1.2083 | X42Cr13 Frequently Asked Questions

Q: What is the difference between 420SS, 1.2083 and X42Cr13?

A: These are equivalent material grades under different standard systems. 420SS is an AISI (US) grade, 1.2083 is a DIN (German) number and X42Cr13 is an EN (European) grade. They essentially represent the same martensitic stainless tool steel with slight differences in allowable composition ranges.Q: How does this material compare to D2 tool steel?

A: Our 420SS/1.2083/X42Cr13 offers significantly better corrosion resistance and slightly better polishability than D2, which offers slightly higher wear resistance due to higher carbon content and larger carbides. In corrosive environments or applications requiring a high surface finish, 420SS/1.2083/X42Cr13 is superior, while D2 may perform better in severe abrasive wear applications.Q: What heat treatments are recommended to obtain maximum hardness?

A: For maximum hardness (54-58 HRC), we recommend austenitising at 1010-1040°C (1850-1900°F) followed by gas or oil quenching. Three tempering cycles of 2 hours each at 150-200°C (300-390°F) provide the best combination of hardness and toughness. For critical applications, customised heat treatment protocols are available.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |