Italy has a long tradition in foundry and die-casting industries, serving key markets such as automotive, aerospace, and industrial machinery. With global demand for lightweight and complex aluminum parts increasing, Italian foundries face growing pressure to improve mold reliability, reduce downtime, and extend service life.

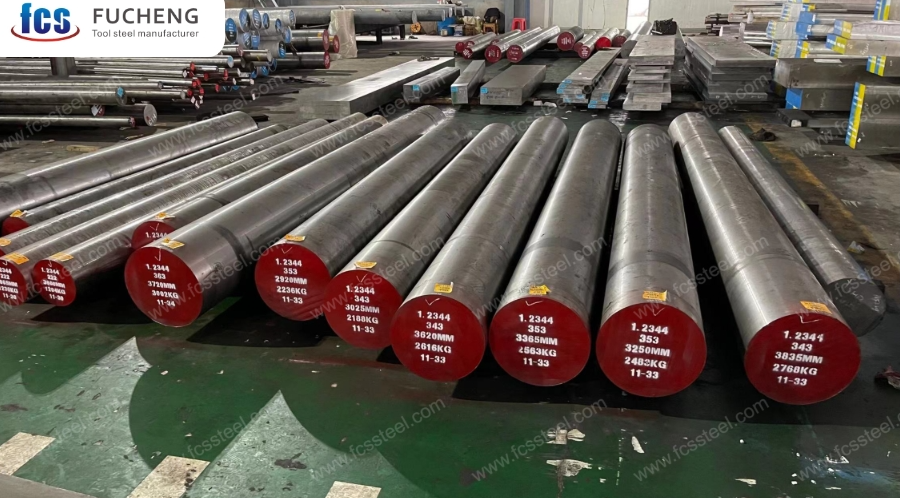

One of the most widely used materials in hot-work tooling is 1.2344 steel (X40CrMoV5-1, equivalent to H13 in ASTM standards). Known for its resistance to thermal fatigue and toughness at elevated temperatures, 1.2344 is the foundation of most mold-making strategies in Italy.

However, material selection alone is not enough. The way foundries process, treat, and maintain 1.2344 molds has a significant impact on their longevity. This article presents the Top 9 practical methods Italian foundries use to maximize mold life, based on proven techniques and industry benchmarks.

1. Optimized Heat Treatment for Uniform Hardness

Proper heat treatment is the starting point for long-lasting molds.

- Target hardness range: Italian toolmakers generally harden 1.2344 to 44–52 HRC, a balance between wear resistance and toughness.

- Quenching strategy: Uniform oil or gas quenching minimizes residual stresses and reduces the risk of cracking.

- Tempering cycles: Triple tempering between 550–600 °C stabilizes the martensitic structure, ensuring long-term thermal stability.

A study from the European Tooling Association indicates that improper heat treatment can reduce die life by 30–40%, while optimized procedures add thousands of casting cycles.

2. Nitriding for Enhanced Surface Hardness

Surface nitriding is widely adopted in Italy to improve mold performance.

- Plasma nitriding creates a hard surface layer (~900–1200 HV) with depths of 0.3–0.6 mm.

- The nitrided layer improves wear resistance and reduces soldering when molten aluminum adheres to the mold surface.

- Distortion is minimal, making it suitable for precision molds.

Italian foundries report that nitrided 1.2344 molds last 40–60% longer in high-volume die-casting compared to untreated molds.

3. PVD and CVD Coatings for Specialized Applications

Beyond nitriding, advanced coatings are applied to combat specific challenges:

- CrN coatings: Reduce soldering and improve corrosion resistance.

- AlTiN coatings: Offer better thermal stability at high injection temperatures.

- CVD coatings: Provide strong adhesion but require higher processing temperatures, often used in large-scale production.

Case studies from Italian automotive suppliers show that coated 1.2344 dies can withstand up to 100,000 cycles in aluminum die casting, compared to 50,000–60,000 cycles for uncoated equivalents.

4. Cooling Channel Optimization

Thermal management is one of the most critical factors in die performance.

- Conventional drilled channels: Common in older tooling, but limited in reaching hot spots.

- Conformal cooling channels (3D printed inserts): Allow precise cooling near problem zones, reducing thermal gradients.

- Water flow rate and pressure monitoring: Ensures consistent cooling, avoiding localized overheating.

In trials conducted by Italian research consortiums in Brescia and Turin, optimized cooling design increased mold life by 20–25%, while also improving cycle times by 10%.

5. Preheating and Controlled Start-Up

Mold damage often occurs during the first few cycles of casting when molds are still cold.

- Italian foundries use induction preheating systems, gradually heating dies to 180–250 °C before production.

- Controlled start-up reduces thermal shock, minimizing crack initiation.

Industry statistics show that proper preheating can extend mold life by up to 15%, preventing early-stage failures.

6. Regular Repair and Refurbishment Strategies

Instead of discarding molds at the first sign of wear, Italian foundries employ systematic refurbishment.

- Laser cladding and TIG welding restore worn areas using compatible filler metals.

- Polishing and re-machining remove heat checks before they propagate into deeper cracks.

- Surface re-nitriding rejuvenates hardness after repair.

By combining refurbishment with scheduled maintenance, Italian foundries have reduced mold replacement frequency by 25–30%, saving significant costs.

7. Lubrication and Release Agent Management

Proper die lubrication reduces wear and soldering.

- Water-based lubricants are most common, sprayed into the cavity between shots.

- Over-lubrication can cause thermal shock, while under-lubrication accelerates wear.

- Some Italian plants employ automated spray systems, ensuring consistent film thickness.

Data from die-casting trials in Lombardy shows that optimized lubrication programs extend mold life by 10–20% while also improving casting surface finish.

8. Monitoring and Predictive Maintenance

Modern Italian foundries integrate digital monitoring to anticipate die wear.

- Thermocouples measure mold surface temperature in real time.

- Acoustic emission sensors detect micro-cracks before failure.

- Predictive software analyzes cycles to forecast die replacement schedules.

This predictive approach reduces unplanned downtime and enables proactive mold refurbishment, aligning with Industry 4.0 initiatives in Italy.

9. Material Selection and Die Design Best Practices

Even within the same steel grade, performance varies based on initial design.

- 1.2344 ESR (Electro-Slag Remelted) variants are preferred in Italy for their superior cleanliness and isotropy.

- Generous radii and optimized gating design reduce stress concentration.

- Insert-based construction allows selective replacement of high-wear zones without scrapping the entire mold.

In practical terms, these design measures have been shown to double tool life in critical applications such as large automotive structural castings.

Case Study: Italian Automotive Die Casting

A leading Italian automotive supplier in Emilia-Romagna implemented a combined strategy:

- ESR-grade 1.2344 steel

- Plasma nitriding + CrN coating

- Conformal cooling channels

- Automated lubrication monitoring

Result: Mold service life increased from 60,000 cycles to over 95,000 cycles, reducing annual tooling costs by 28% while maintaining high-quality standards for engine components.

Conclusion

For Italian foundries, extending mold life is not just a technical challenge—it is a strategic necessity to remain competitive in Europe’s highly demanding automotive and aerospace markets.

By focusing on nine proven strategies—from heat treatment and nitriding to digital monitoring and predictive maintenance—Italian foundries maximize the performance of 1.2344 steel molds, reduce operational costs, and ensure consistent casting quality.

As the industry moves toward sustainability and efficiency, these practices will continue to set the benchmark for die performance in Italy’s foundry sector.