Leipzig, Germany, is home to a growing number of die casting facilities that serve automotive, machinery, and precision engineering industries. In particular, the region’s automotive suppliers produce aluminum and magnesium castings for body structures, engine housings, and transmission components.

One of the central challenges for die casting plants in Leipzig is managing heat fatigue. Molds undergo constant heating and cooling, leading to cracking, distortion, and dimensional instability. The choice of tool steel directly impacts mold life and cost efficiency.

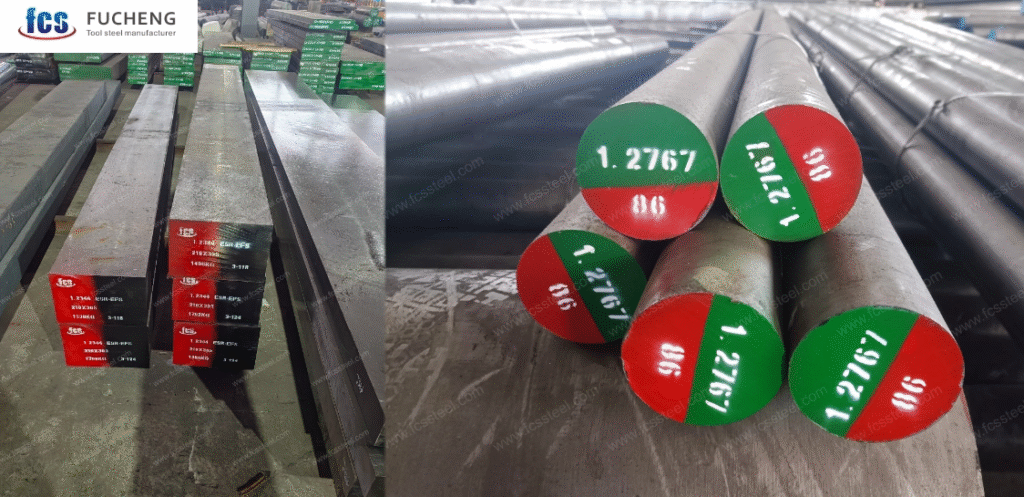

Two steels often evaluated are:

- 1.2767 (X45NiCrMo4, a high-toughness tool steel)

- 1.2344 (X40CrMoV5-1, also known as H13, a hot work tool steel)

This article compares their heat-fatigue resistance, tempering behavior, and suitability for large dies, providing recommendations for German die casting plants.

1. Overview of 1.2767 Tool Steel

- Classification: High-toughness cold work/tool steel.

- Chemical Composition (approx.):

- C: 0.45%

- Ni: 4.0%

- Cr: 1.3%

- Mo: 0.3%

- Key Properties:

- Exceptional toughness and ductility.

- Good hardenability (through-hardened sections up to 400 mm).

- Stable hardness up to ~200–250 °C.

- Limitations:

- Not primarily designed for hot work; limited resistance to thermal shock and fatigue.

- Reduced surface stability under long-term exposure to >300 °C.

Typical uses: heavy-duty shear blades, cold extrusion dies, large tools requiring toughness.

2. Overview of 1.2344 Tool Steel (H13)

- Classification: Hot work tool steel, widely used in die casting.

- Chemical Composition (approx.):

- C: 0.39%

- Cr: 5.2%

- Mo: 1.3%

- V: 1.0%

- Key Properties:

- Excellent thermal fatigue resistance.

- High tempering resistance up to 600 °C.

- Strong resistance to hot wear and heat checking.

- Dimensional stability in cyclic heating/cooling.

Typical uses: aluminum die casting dies, hot extrusion dies, forging tools, molds for plastics with high glass fiber content.

3. Heat-Fatigue Performance Comparison

3.1 Thermal Fatigue Cracking

- 1.2767: High toughness delays crack propagation, but its surface softens quickly under repeated heating. Micro-cracks form earlier.

- 1.2344: Specially optimized for hot work; resists heat checking and micro-cracking under 10,000+ heating cycles.

For Leipzig’s high-volume aluminum die casting, 1.2344 provides longer die life.

3.2 Tempering Resistance

- 1.2767: Retains hardness only up to ~250 °C. Beyond this, mechanical properties degrade rapidly.

- 1.2344: Maintains strength and hardness up to ~600 °C; suitable for molds exposed to molten aluminum (~680–720 °C surface contact).

For thermal stability, 1.2344 clearly outperforms.

3.3 Large Mold Applications

- 1.2767: Deep hardenability makes it attractive for thick-section dies where toughness is critical. However, thermal fatigue remains a risk.

- 1.2344: Can be hardened uniformly up to medium-large sizes; better surface protection against hot wear and cracking.

In Leipzig’s automotive die casting shops, where dies weigh several tons, 1.2344 with proper cooling design is usually favored.

4. Supporting Data from Industry Studies

- A Fraunhofer IFAM study (2019) showed that H13/1.2344 steels lasted up to 2.5× longer than Ni-alloyed steels like 1.2767 in cyclic aluminum casting trials.

- Die life expectancy (average values in high-pressure die casting):

- 1.2767: 50,000–80,000 shots (before critical cracking).

- 1.2344: 100,000–200,000 shots (depending on cooling and treatment).

- Hardness stability test results:

- 1.2767: Drops from 52 HRC to 38 HRC after 200 hours at 400 °C.

- 1.2344: Maintains >45 HRC after 400 hours at 500 °C.

These numbers highlight why German OEM suppliers often standardize on 1.2344 for hot work dies.

5. Cost and Maintainability

| Factor | 1.2767 | 1.2344 |

|---|---|---|

| Raw Steel Cost | Medium | Medium-High |

| Machinability | Good | Moderate |

| Heat Treatment | Simpler | Requires precise control |

| Die Maintenance | Frequent surface refurbishment | Longer intervals |

| Life Cycle Cost | Higher (due to downtime) | Lower (due to extended life) |

Even if 1.2344 costs more upfront, Leipzig die shops report 15–25% lower total tooling costs over full production runs.

6. Practical Selection Guidelines for Leipzig Die Casting

- For long-run aluminum die casting (>100,000 shots) → choose 1.2344.

- For short-run, thick-section dies requiring toughness → 1.2767 may still be considered.

- For magnesium or high-pressure automotive parts → 1.2344 is superior due to higher thermal fatigue resistance.

- For hybrid dies → use 1.2767 as a backing steel and 1.2344 as inserts in high-heat areas.

7. Future Outlook in Germany’s Die Casting Sector

- Shift toward sustainable production: Longer die life reduces waste and energy use.

- Surface treatments: Nitriding, PVD, and laser cladding extend 1.2344 die performance further.

- Material hybrids: German toolmakers increasingly combine steels for optimized cost/performance.

Conclusion

In Leipzig’s die casting industry, the choice between 1.2767 and 1.2344 depends on balancing toughness vs thermal fatigue resistance.

- 1.2767 offers exceptional toughness and deep hardenability but lacks hot strength, making it less suited for long-run aluminum die casting.

- 1.2344 (H13) delivers superior heat-fatigue resistance, tempering stability, and longer service life, making it the default choice for most German die casting applications.

For procurement managers and engineers in Leipzig, the decision is clear:

- Use 1.2344 for high-volume aluminum/magnesium casting.

- Use 1.2767 selectively for thick dies or hybrid tool designs.

This approach maximizes productivity, tool life, and cost-efficiency, while supporting Germany’s emphasis on high-quality, sustainable manufacturing.