I know choosing between 1.2344 and H13 tool steels can be tricky. Both promise excellent performance, so what makes them different? From my experience, you may need a steel that can handle intense heat without cracking. This is where small differences in their chemical makeup become important. I suggest you look at one overlooked detail. It could be the deciding factor for your projects.

Chemical Composition and Purity

When comparing 1.2344 (DIN standard) with H13 (AISI standard), their chemical elements are nearly the same, both belonging to the Cr-Mo-V alloy family.

- Carbon (C): around 0.35–0.40%

- Chromium (Cr): about 5%

- Molybdenum (Mo): 1.1–1.5%

- Vanadium (V): 0.8–1.2%

- Silicon (Si): ~1%

The subtle distinction is that 1.2344 usually has a narrower carbon range, which improves toughness and thermal stability compared with standard H13.

Steel Purity and ESR

Both grades are available in conventional production or with ESR (Electroslag Remelting) treatment. ESR minimizes inclusions and refines the grain, which translates into better toughness and fatigue life.

- Standard impurity level: P ≤ 0.030%, S ≤ 0.030%

- ESR version: P ≤ 0.030%, S ≤ 0.020%

👉 In demanding tooling environments, ESR variants clearly extend service life.

International Standards

Though labeled differently, the steels are essentially equivalent across regions:

- Europe (DIN EN ISO 4957): 1.2344

- USA (ASTM A681): H13

- Japan (JIS G4404): SKD61

- China (GB/T 1299): 4Cr5MoSiV1

- UK (BS 4659): BH13

- International EN number: X40CrMoV5-1

Market Tendencies

- Europe: prefers 1.2344 for its controlled composition and dimensional stability.

- North America: uses H13 widely due to broader chemistry acceptance.

- Asia (China/Japan): SKD61/GB grades dominate automotive and die-casting sectors.

- UK: emphasizes certification and traceability over naming.

Conclusion: The choice often depends less on performance differences and more on which regional standard your project follows.

Heat Resistance and High-Temperature Stability

For hot-work applications, stability at elevated temperatures is critical.

- 1.2344: Retains hardness more effectively above 600 °C, showing higher resistance to heat checking and cracking.

- H13: Performs reliably, though it tends to lose hardness faster under continuous high-heat exposure.

Heat Treatment Practice

- H13: Quench 1000–1050 °C, temper 540–650 °C → final hardness 48–52 HRC.

- 1.2344: Quench 1020–1050 °C, temper 550–600 °C (usually 2–3 cycles) → hardness 48–50 HRC with enhanced stability.

Result: For intensive thermal cycling (like high-volume aluminum die casting), 1.2344 generally outperforms H13 in long-term stability.

Wear Resistance and Impact Toughness

- Wear resistance: Both grades rely on vanadium carbides for abrasion resistance, making them equally capable in wear-dominated applications.

- Toughness: 1.2344 gains a slight edge thanks to its tighter control of carbon, reducing the tendency for cracking under heavy mechanical and thermal stress.

👉 In real-world conditions (e.g., aluminum or magnesium die casting), 1.2344 dies typically last longer before surface cracking appears, reducing downtime.

Machining and Processing

Both steels are known for moderate-to-good machinability.

- H13: Machinability rating ~55% (relative scale for tool steels).

- 1.2344: Similar, but with more uniform response after heat treatment.

Processing Notes

- Use coated carbide tools for longer tool life.

- Employ rich coolant supply to avoid overheating.

- Preheating blocks reduces thermal shock risk.

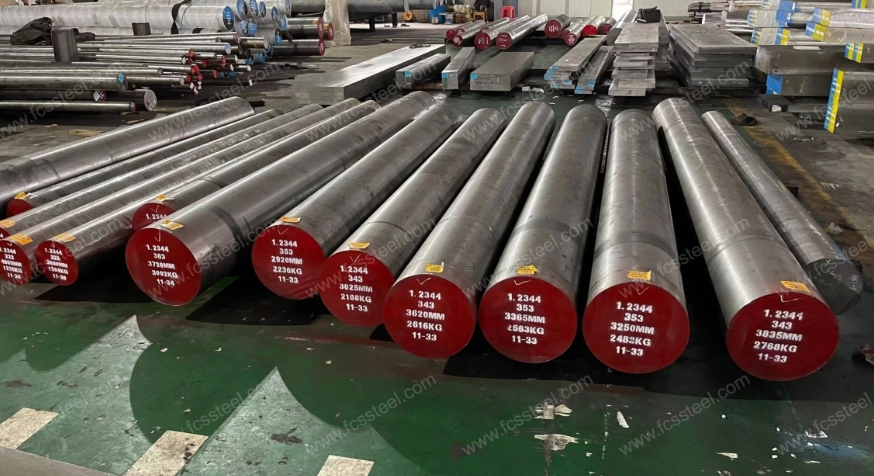

- Available in plates, bars, forged blocks, and hollow forms.

Heat treatment:

- H13: Typically double tempered.

- 1.2344: Triple tempering often recommended for dimensional consistency.

Hardenability and Dimensional Accuracy

Both are air-hardening steels with final hardness between 48–54 HRC after quench and temper.

- 1.2344: Narrow chemistry range leads to more predictable hardening and size control.

- H13: Good hardenability, but slightly higher risk of distortion in tight-tolerance tools.

Summary: If dimensional stability and minimal distortion are priorities, 1.2344 is preferable.

Cost and Supply Factors

Pricing (approximate, per ton)

- H13: around $5,500/ton for standard grade; $20,000–28,000/ton for ESR or premium-quality material.

- 1.2344: about $6,500/ton for regular grade, with ESR and high-purity types reaching comparable premium levels.

👉 In global markets, both grades generally trade in the $5,000–30,000/ton range, depending on order size, treatment method, and supplier reputation.

Global Availability

- H13: Stocked more widely, especially for small- to medium-batch purchases.

- 1.2344: Common in Europe and Asia; bulk orders are sometimes required in regions dominated by ASTM specifications.

Practical Selection Guide

- Choose 1.2344 when:

- High thermal fatigue resistance is critical.

- Dimensional precision after heat treatment is required.

- Longer service life is worth slightly higher cost.

- Choose H13 when:

- Lower price and faster delivery are key.

- The project operates under moderate heat cycles.

- Local supply chains primarily support ASTM/ANSI standards.

1.2344 vs H13 Tool Steel: Detailed Comparison for Industrial Buyers

Buying Recommendations

For buyers such as wholesalers, distributors, and trading companies, the decision between 1.2344 and H13 should balance cost, availability, and application requirements.

- When to Choose 1.2344:

- Projects that involve high thermal loads such as aluminum die casting, hot forging, or extrusion.

- Customers requiring dimensional accuracy after heat treatment and longer tool life.

- Markets in Europe and Asia, where DIN/EN standards are widely accepted.

- When to Choose H13:

- Projects that emphasize cost efficiency and shorter lead times.

- Applications with moderate heat cycles or where dimensional tolerances are less demanding.

- Regions such as North America, where ASTM/ANSI standards are dominant.

- Price Consideration:

- Standard grades typically range from $5,000–7,000/ton.

- ESR and high-purity grades can reach $20,000–30,000/ton.

- Bulk purchasing directly from mills or authorized distributors usually secures better discounts.

- Supply Strategy:

- Maintain dual sourcing (both 1.2344 and H13) if you serve multiple regions, ensuring compatibility with local standards.

- For long-term cost savings, investing in ESR-grade 1.2344 can reduce tool replacement frequency, even if initial cost is higher.

Final Conclusion

Both 1.2344 and H13 are reliable and widely recognized hot-work tool steels. The choice largely depends on your end market standard, technical requirements, and budget planning.

- Select 1.2344 for superior high-temperature stability and dimensional consistency.

- Select H13 for broader availability and more cost-sensitive projects.

By carefully aligning your procurement strategy with market demand and regional standards, you can maximize both tool performance and profitability.

Final Thoughts

While 1.2344 and H13 are practically interchangeable, subtle differences can impact tool life and performance:

- 1.2344: Best for extreme hot-work conditions, stable hardness, and tighter tolerances.

- H13: Excellent all-rounder with cost and availability advantages.

Ultimately, the decision depends on:

- End-use application (die casting, forging, extrusion).

- Regional standards (DIN vs ASTM).

- Budget and sourcing strategy.

By evaluating these three aspects, buyers can match the steel grade to both technical and economic requirements.