Birmingham has long been recognized as one of the UK’s leading centers for advanced manufacturing and precision tooling. The city’s heritage in automotive, aerospace, and metal forming has created a strong ecosystem of die makers, press tool manufacturers, and heat-treatment specialists.

When selecting tool steels, the decision often comes down to the application environment. For operations requiring high-temperature resistance, 1.2344 (H13) is a preferred hot-work tool steel. For cutting, stamping, and forming cold materials, D2 (DIN 1.2379) remains one of the most popular cold-work grades.

This article compares 1.2344 and D2 tool steels in the Birmingham, UK context, focusing on their composition, heat treatment, properties, and application suitability, with the goal of helping buyers and engineers make the right choice.

1. Background: Hot vs Cold Work Tool Steels

Tool steels are broadly divided into:

- Hot-work tool steels → optimized for high-temperature tooling (forging, die casting, extrusion).

- Cold-work tool steels → designed for wear resistance, strength, and toughness at room temperature.

1.1 Hot Work Steels (1.2344)

- Function in environments exceeding 400–600 °C.

- Key requirements: thermal fatigue resistance, hot hardness, resistance to cracking during repeated heating and cooling.

1.2 Cold Work Steels (D2 / 1.2379)

- Used for cutting and forming at room or slightly elevated temperatures.

- Key requirements: wear resistance, edge retention, dimensional stability.

In practice, 1.2344 excels in high-temperature tooling, while D2 dominates cold stamping and blanking.

2. Chemical Composition Comparison

2.1 Typical Composition Ranges

| Element | 1.2344 (H13) Hot Work | D2 (1.2379) Cold Work |

|---|---|---|

| C | 0.38–0.42% | 1.50–1.60% |

| Cr | 4.8–5.5% | 11.0–13.0% |

| Mo | 1.2–1.5% | 0.7–1.0% |

| V | 0.85–1.2% | 0.9–1.1% |

| Si | 0.8–1.2% | 0.1–0.4% |

| Mn | 0.25–0.5% | 0.25–0.45% |

👉 The high chromium in D2 (≈12%) gives it outstanding wear resistance and corrosion tolerance in dry environments, while the balanced Cr-Mo-V in 1.2344 provides thermal shock resistance.

3. Heat Treatment Routes

3.1 1.2344 Steel

- Preheating: 600–650 °C then 850–900 °C

- Austenitizing: 1000–1040 °C

- Quenching: air, oil, or vacuum furnace

- Tempering: 3 cycles, 540–620 °C

Performance after HT:

- Hardness: 44–52 HRC

- High tempering stability

3.2 D2 Steel

- Preheating: 450–500 °C then 850–900 °C

- Austenitizing: 1020–1040 °C

- Quenching: air or gas (vacuum)

- Tempering: 200–500 °C (secondary hardness peak ~520 °C)

Performance after HT:

- Hardness: 58–62 HRC

- Exceptional wear resistance

4. Mechanical Properties in Application Context

| Property | 1.2344 Steel (Hot Work) | D2 Steel (Cold Work) |

|---|---|---|

| Hardness (HRC) | 44–52 | 58–62 |

| Toughness (Charpy V) | High | Medium |

| Wear resistance | Medium | Very High |

| Heat resistance | Excellent (600+ °C) | Poor (>200 °C weakens) |

| Dimensional stability | Good | Excellent |

| Typical application life | 10,000–100,000 cycles | 100,000+ cuts (stamping) |

5. Application Domains in Birmingham, UK

5.1 Automotive Sector

- 1.2344: Die-casting tools for aluminum engine blocks and transmission housings.

- D2: Blanking dies for sheet metal cutting in car body panels.

5.2 Aerospace Industry

- 1.2344: Forging dies for turbine components, where high heat cycles dominate.

- D2: Cutting tools for titanium and nickel alloys at room temperature.

5.3 General Engineering and Tooling

- 1.2344: Extrusion dies for plastic and non-ferrous alloys.

- D2: Industrial knives, shear blades, and punches.

6. Market and Supply Context in the UK

- Birmingham suppliers often stock both grades due to demand from automotive (Jaguar Land Rover, supply chains) and aerospace sectors.

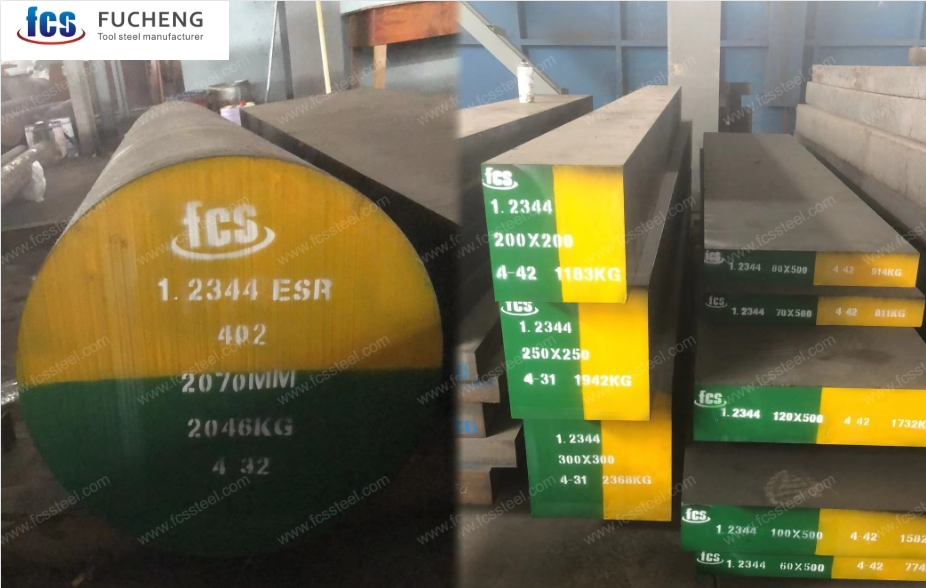

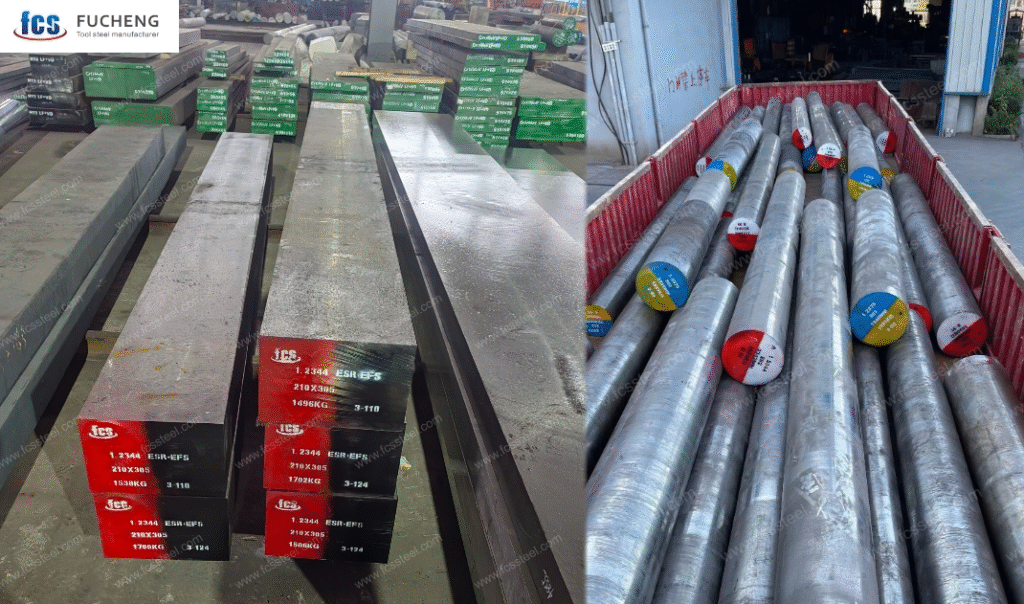

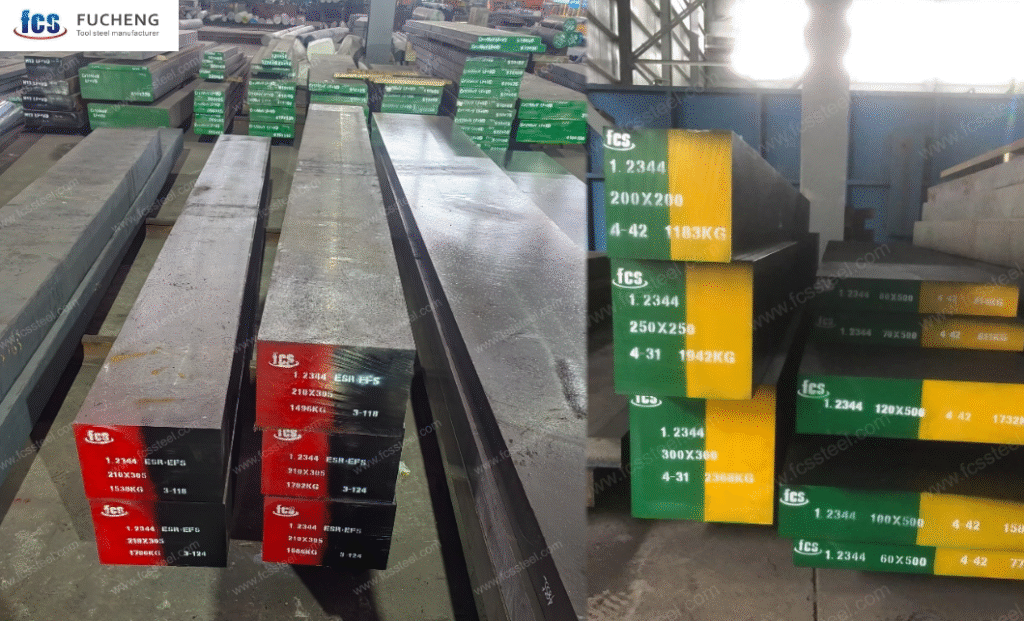

- According to UK Steel Federation reports (2024), tool steel imports from Germany and Sweden dominate, but UK stockholders carry 1.2344 ESR (Electro-Slag Remelted) for premium tooling.

- Price difference:

- D2 (cold work) ~ 10–15% cheaper per tonne than 1.2344 ESR grades.

- 1.2344, however, justifies cost with longer die life in hot conditions.

7. Practical Selection Guidelines for Birmingham Buyers

7.1 When to Choose 1.2344 (H13)

- High-temperature cycles (>400 °C).

- Need for resistance to thermal shock.

- Large hot-work dies (forging, extrusion, die casting).

7.2 When to Choose D2 (1.2379)

- Cold stamping, blanking, and forming.

- Applications where wear resistance > toughness.

- Tools requiring dimensional stability after heat treatment.

8. Procurement Checklist (Birmingham Context)

| Item | 1.2344 Steel Buyer Requirements | D2 Steel Buyer Requirements |

|---|---|---|

| Chemical composition cert. | Cr-Mo-V balance verified | Cr 11–13% verified |

| Hardness report | 44–52 HRC post HT | 58–62 HRC post HT |

| UT inspection | EN 10228-3 Class 3 | Optional (smaller tools) |

| Packaging | Anti-rust + traceable stamping | Anti-rust + traceable stamping |

| Warranty clauses | Hot fatigue resistance | Wear resistance guarantee |

9. Cost-Saving Tips for UK Buyers

- Consolidated orders: Larger batch imports reduce per-tonne logistics.

- Spot vs contract buying: For 1.2344, contract buying stabilizes alloy surcharges (Mo/Cr).

- ESR vs standard: ESR improves tool life but costs 15–20% more; consider for high-value dies only.

- Third-party inspection in EU: Prevents receiving sub-spec materials.

10. Conclusion

The comparison of 1.2344 vs D2 highlights a fundamental difference: hot vs cold work.

- 1.2344 steel (H13) is the go-to material for Birmingham’s hot-work die casting, forging, and extrusion tools, thanks to its resistance to thermal fatigue and cracking.

- D2 steel (1.2379) dominates cold stamping, cutting, and wear-intensive operations, thanks to its hardness and edge retention.

For toolmakers in Birmingham, the choice is not about which steel is better, but which steel matches the application environment. By aligning procurement specifications, heat treatment requirements, and supplier clauses, manufacturers can maximize productivity while controlling long-term costs.