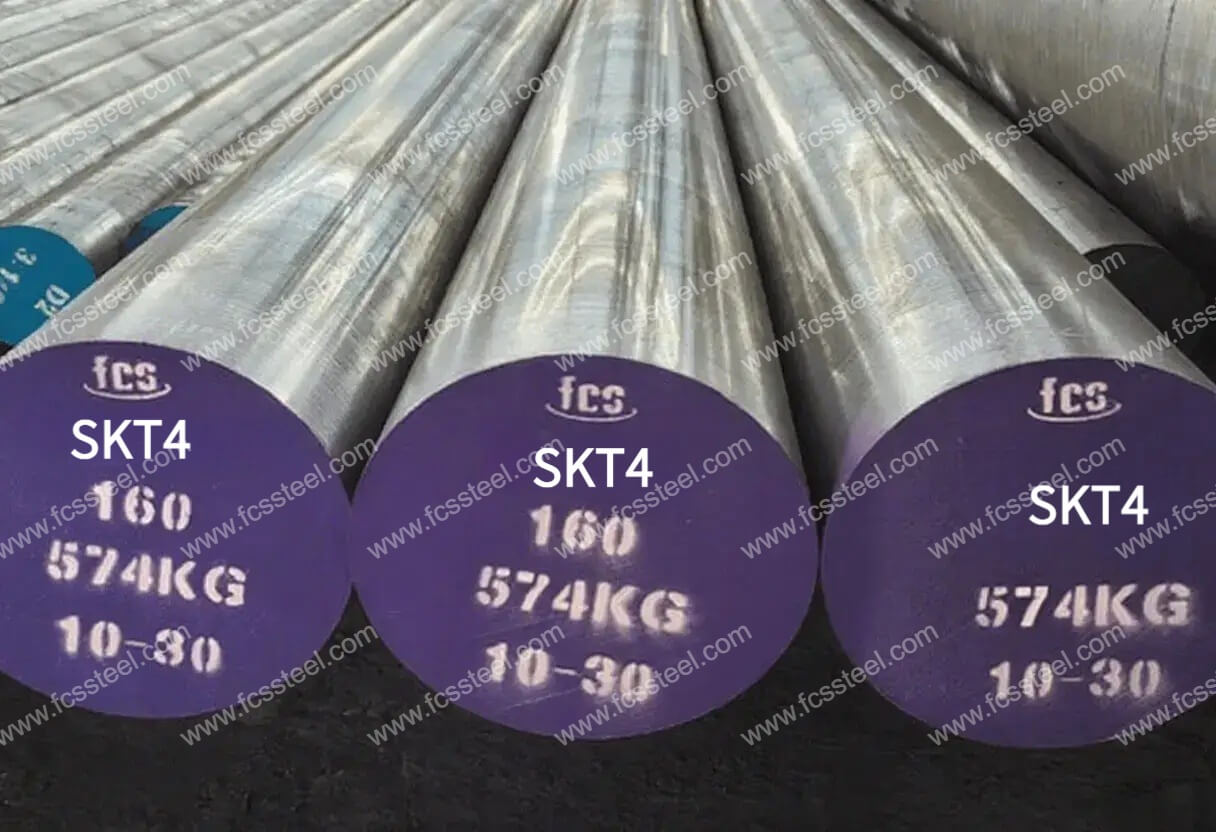

SKT4 Tool Steel

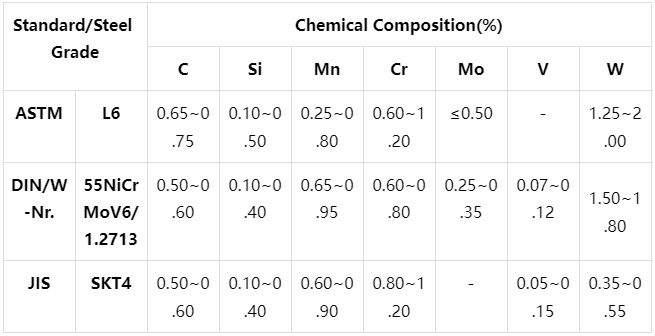

SKT4 tool steel is a premium grade hot work mould steel designed to meet the challenges of high temperature forming operations. Where conventional tool steels fail under extreme thermal and mechanical stresses, SKT4 retains its structural integrity and performance properties.The Japanese standard JIS SKT4 tool steel corresponds to the American standard L6, and the German standard ASTM is 55NiCrMoV6/1.2713 tool steel.

SKT4 solves the problem of premature tool failure in hot work applications through its optimised chemistry and specialised heat treatment process, providing excellent resistance to thermal fatigue and longer service life. The result is significantly lower tooling costs, reduced production interruptions and consistent end product quality over longer production runs.

SKT4 Tool Steel Product Introduction

SKT4 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SKT4 Mould Steel:

SKT4 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- SKT4 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

SKT4 Tool Steel Chemical Composition

SKT4 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

SKT4 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

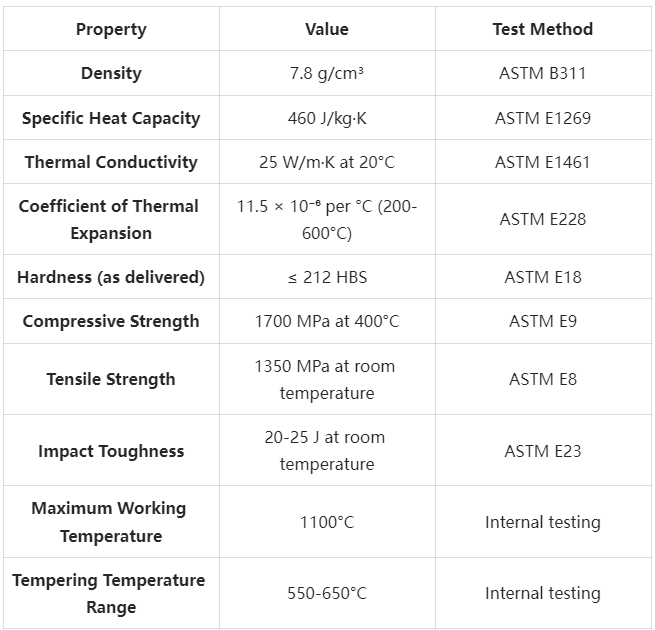

SKT4 Tool Steel Technical Specifications

SKT4 Tool Steel Product Applications

Main application scenarios

Extrusion tooling

For aluminium extrusion tooling with operating temperatures up to 550°C, SKT4 provides the critical combination of wear resistance and thermal stability required to maintain precise profiles over long production runs. The steel's excellent thermal hardness prevents premature wear of bearing surfaces, while its resistance to thermal fatigue prevents corner and thin section cracking. Extrusion companies report up to 40% longer die life and improved surface finish of extruded products when using SKT4 dies compared to conventional hot work steels.

Hot shear applications

In hot shear and dressing operations, SKT4 maintains a sharp cutting edge at high temperatures where other steels soften and deform. The combination of high thermal hardness and good toughness prevents both premature passivation and catastrophic failure due to chipping. Steel processors using SKT4 for hot dressing operations report up to 50 per cent longer insert life and less downtime for insert replacement and maintenance.

Pressure die casting tools

For pressure die casting tools that handle copper and brass alloys, SKT4 offers excellent resistance to thermal fatigue cracking and thermal splitting. The steel's ability to maintain dimensional stability and resist plastic deformation under a combination of thermal and mechanical loads ensures consistent part quality and longer tool life. Die casting operations report significant reductions in maintenance costs and increases in productivity when using SKT4 for cores, ejectors and inserts.

Industry-specific applications

- Automotive: transmission housings, engine blocks, wheel components.

- Aerospace: turbine components, structural parts, landing gear components.

- Consumer products: appliances, power tools, electronics housings.

- Construction equipment: hydraulic component moulds, structural parts.

SKT4 Tool Steel Competitive Advantage Comparison

SKT4 Tool Steel Customer Success Stories

SKT4 Tool Steel Pricing Structure Information

SKT4 Tool Steel Frequently Asked Questions

Q: How does SKT4 compare to standard H13 in die casting applications?

A. SKT4 typically lasts 35-45% longer than H13 tool steel in aluminium die casting applications due to superior thermal fatigue resistance and better retention of thermal hardness. This reduces thermal cracking and reduces plastic deformation during long production runs.Q: What are the key factors affecting the performance of SKT4 in service?

A. The key factors are proper heat treatment, operating temperature, cooling conditions, surface finish quality, and loading conditions. Our application engineers can help you optimise these factors for your specific application.Q: How does the typical cost of SKT4 compare to standard H13 over the life of the tool?

A. Although the initial cost of SKT4 is 15-25 per cent higher than H13, the total life cycle cost is typically 25-35 per cent lower due to extended service life, reduced downtime, fewer replacement tools and lower maintenance requirements.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |