SKH2 Tool Steel

SKH2 high speed tool steel is a high carbon, high tungsten alloyed high speed steel equivalent to the international standard ASTM T1 grade. As a leading tool steel manufacturer, FCS Factory’s SKH2 steel is designed to solve the problem of rapid tool wear during high-intensity cutting.

While conventional tool steels tend to soften and fail at high temperatures and pressures, resulting in frequent tool changes, increased downtime and reduced machining accuracy, FCS TOOL STEEL’s SKH2 steels are optimised for red hardness and wear resistance through the optimisation of the elemental ratios of carbon, tungsten, molybdenum, vanadium and chromium.

Customers applying FCS Factory’s SKH2 tool steel have experienced an average 40% increase in tool life, 25% improvement in machining accuracy, and significant improvements in productivity. This makes it an ideal material choice for high-precision cutting tools, stamping dies and precision measuring tools.

SKH2 Tool Steel Product Introduction

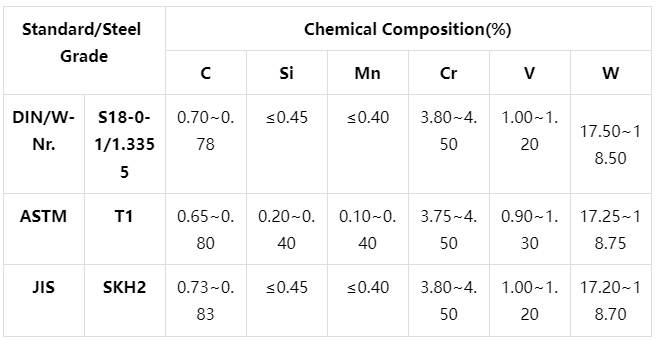

SKH2 tool steel is a tungsten high-speed tool steel that conforms to the Japanese Industrial Standard (JIS G4403) and belongs to the category of Rheinzite steels, which are also known as ‘white’ or ‘sharp’ steels due to their air-cooled hardening properties. Corresponding to the U.S. ASTM grade is T1, Germany DIN / W-Nr grade is S18-0-1/1.3355. Its chemical composition to high carbon and high tungsten as the core, supplemented by chromium, vanadium and other elements, strict control of phosphorus, sulfur impurities. It has excellent red hardness (HRC63 at 600℃) and excellent high temperature wear resistance (HRC66 at 540℃).

SKH2 Tool Steel Types and Options

The table below shows the size range, surface condition and tolerance details for SKH2 Mould Steel:

SKH2 Tool Steel Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

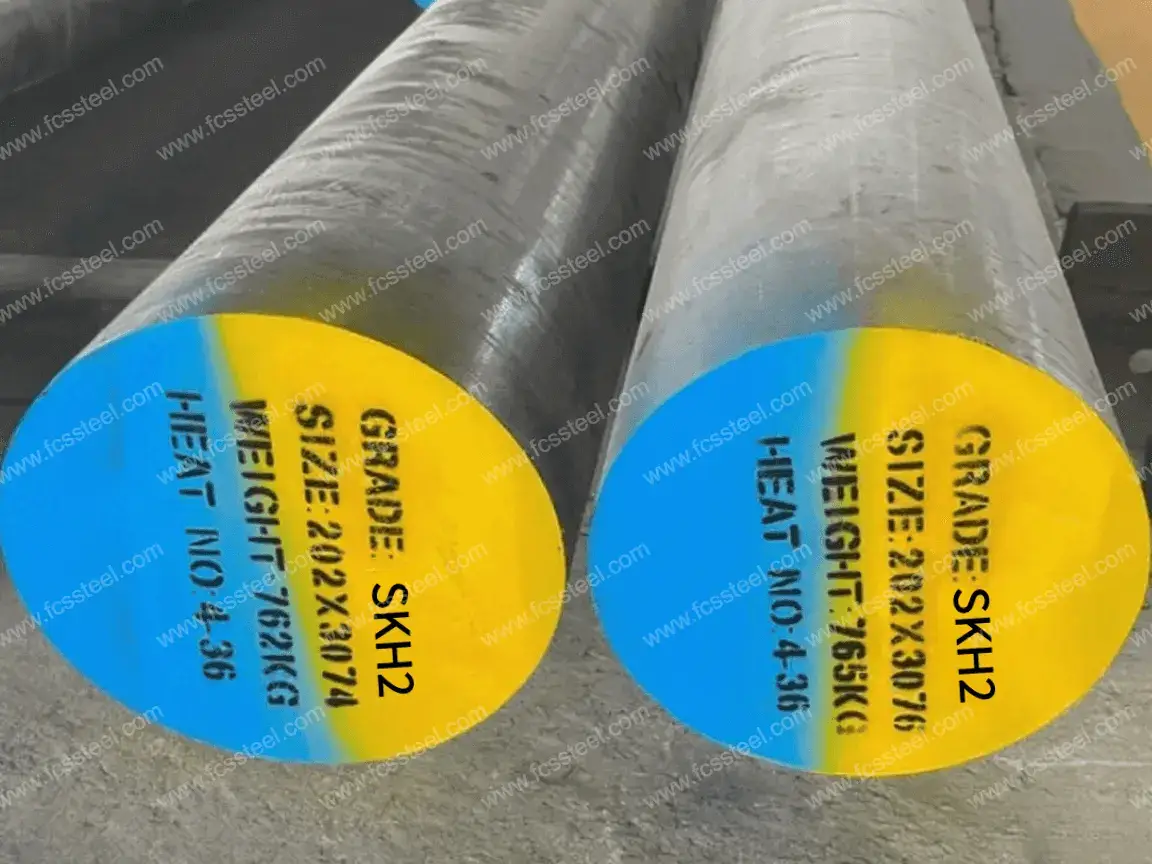

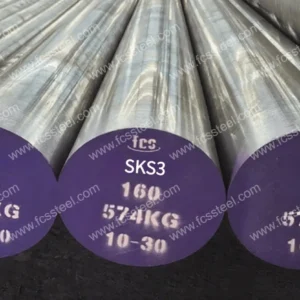

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- SKH2 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

SKH2 Tool Steel Chemical Composition

SKH2 Tool Steel Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

SKH2 Tool Steel Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

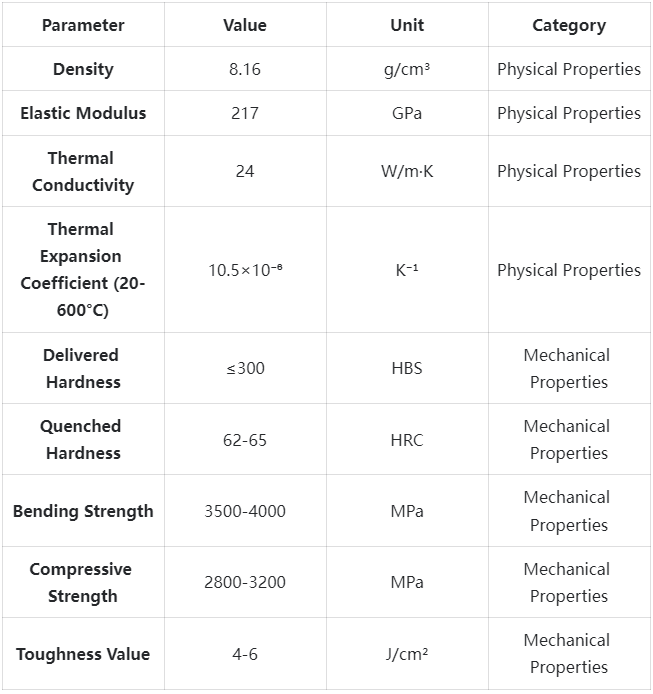

SKH2 Tool Steel Technical Specifications

SKH2 Tool Steel Product Applications

Main application scenarios

High Speed Cutting Tool Applications

Precision mould applications

Measuring Tool Applications

Industry-specific applications

- Aerospace: High-performance cutting tools for titanium and high-temperature alloys

- Automotive: Stamping dies and precision component machining for high-strength steel plates

- Electronics: Precision stamping of electronic connectors and fine assemblies

- Medical Devices: Precision machining tools for surgical instruments and implants

- Mould Manufacturing: Long-life, high-precision core components for injection and stamping tools

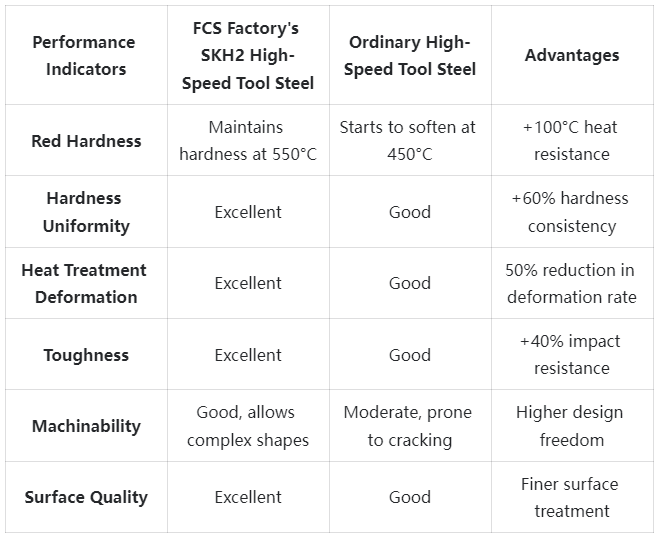

SKH2 Tool Steel Competitive Advantage Comparison

SKH2 Tool Steel Customer Success Stories

SKH2 Tool Steel Pricing Structure Information

SKH2 Tool Steel Frequently Asked Questions

Q: What is the difference between SKH2 and M2 tool steel?A. SKH2 is a Chinese standard grade that corresponds to the international standard M2 grade. The two steels have essentially the same chemical composition and properties and are medium alloyed high speed steels used primarily for cutting tools and wear resistant applications.Q: What materials is SKH2 suitable for?A. SKH2 is particularly suitable for machining materials with a hardness of 30-55 HRC, including carbon steels, alloy steels, stainless steels, grey cast irons and non-ferrous metals. For higher hardness materials, we recommend considering SKH9 or powdered HSS.Q: How can I extend the life of my SKH2 tools?A: The key is to use the correct cutting parameters, proper coolant, avoid overheating, and use hard coatings such as TiN or TiAlN. We offer comprehensive usage guidelines to maximise tool life.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-300x300.png)