1.2550 Tool Steel | 60WCrV7

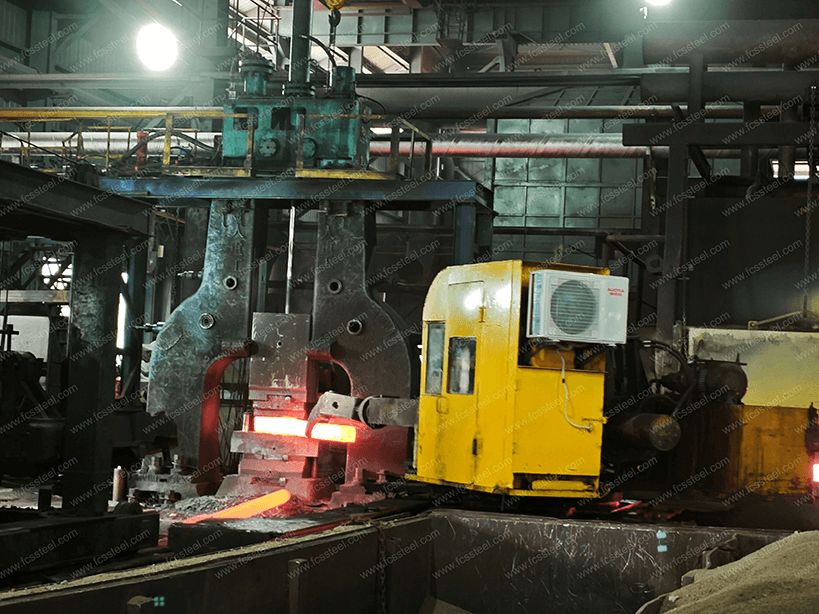

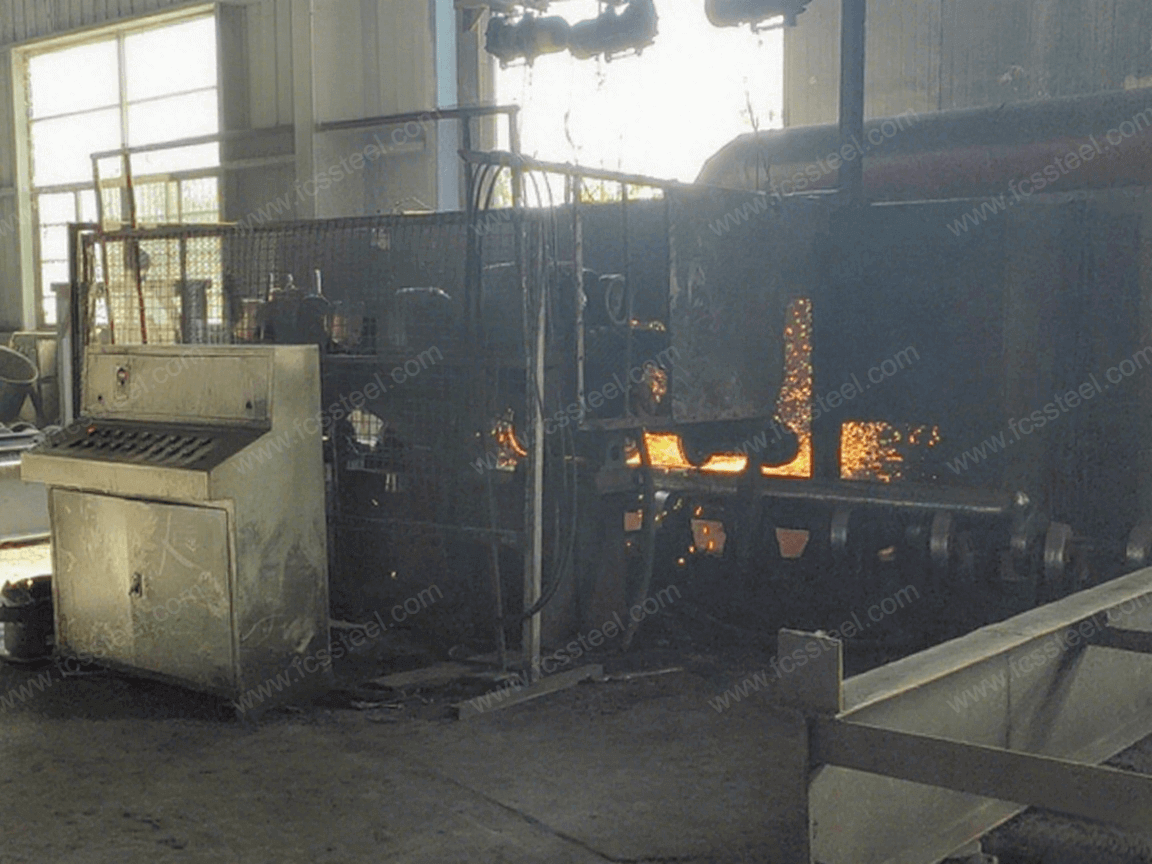

FCS Factory’s 1.2550 and 60WCrV7 tool steels represent the pinnacle of high carbon steel technology and are designed for applications requiring superior wear resistance and edge retention. These premium tool steels are designed to achieve optimum hardness while retaining the necessary toughness through precise control of carbon content and alloying elements.

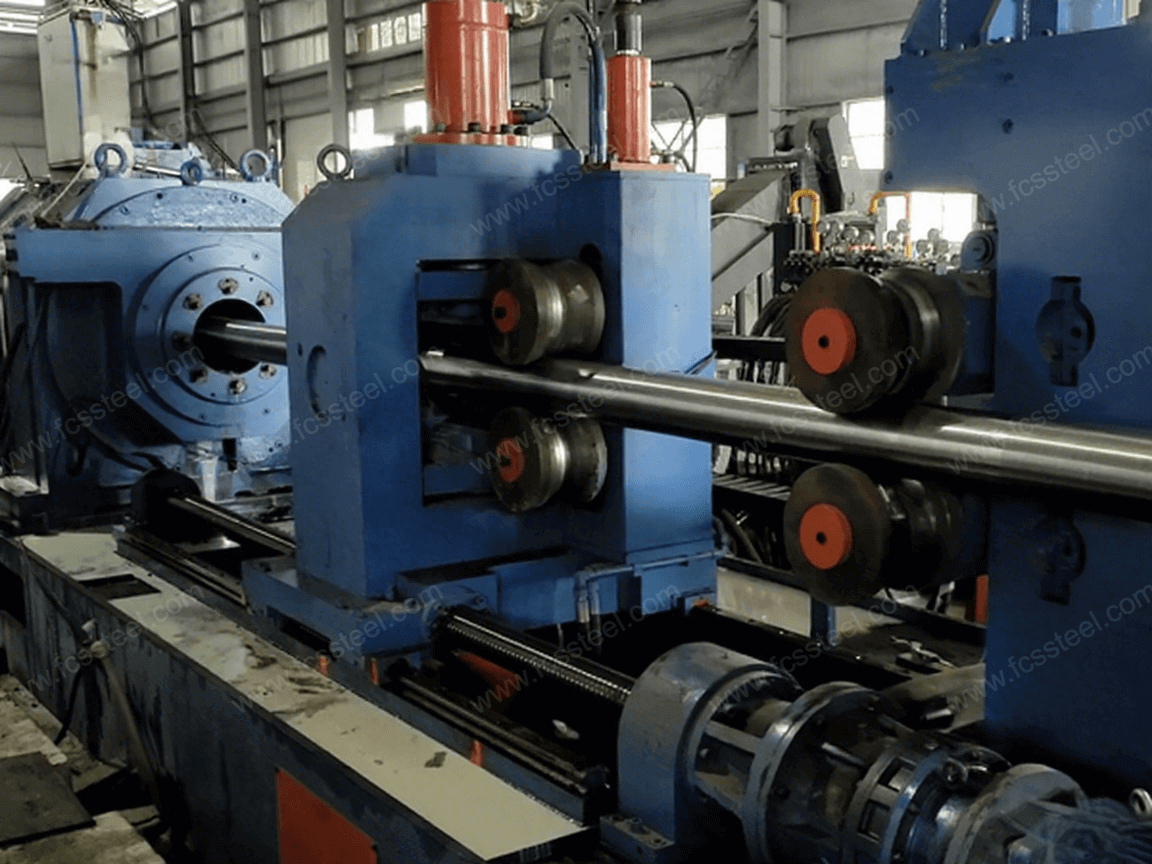

FCS TOOL STEEL‘s tightly controlled manufacturing process ensures consistent material microstructure for predictable heat treatment response and uniform performance. This allows manufacturers to produce with confidence and consistent performance from batch to batch.

The immediate benefits to your operations are extended tool life, reduced maintenance downtime, and ultimately a lower total cost of ownership for high wear applications such as cutting tools, industrial moulds, shear blades and more. Customer feedback shows that FCS TOOL STEEL product life is typically 15-30% longer compared to standard tool steels.

1.2550 Tool Steel | 60WCrV7 Product Introduction

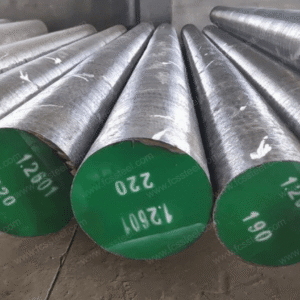

1.2550 Tool Steel

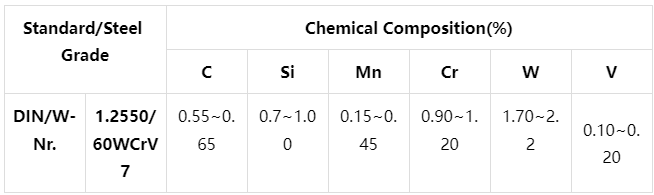

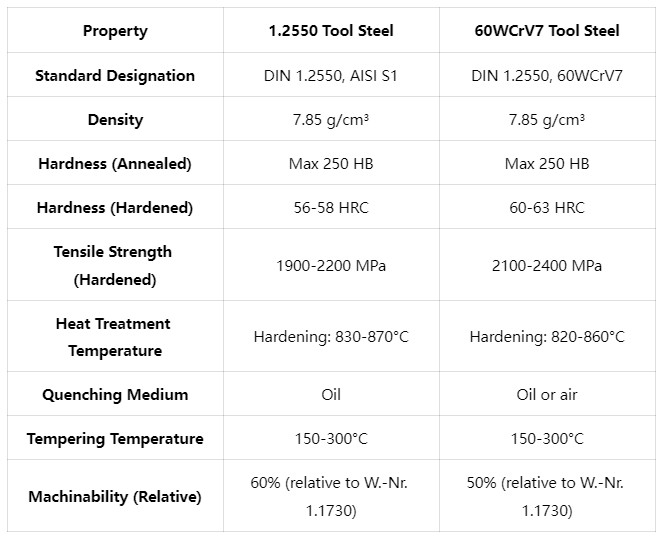

1.2550 tool steel is a high carbon, chromium, tungsten, tungsten and vanadium alloyed tool steel classified as an impact resistant rutile steel under the German W-Nr/DIN standard. Its typical chemical composition consists of carbon (0.55-0.65%), chromium (0.90-1.20%), tungsten (1.80-2.10%) and vanadium (0.10-0.20%), with high hardenability achieved through optimised carbide distribution, High toughness and hardness of 58-62 HRC after heat treatment are achieved through optimised carbide distribution, together with a low coefficient of thermal expansion (11.0×10-⁶/K at 20-100°C) and good thermal stability.

60WCrV7 Tool Steel

60WCrV7 tool steel is the equivalent grade of 1.2550 steel and is a high-alloyed, impact-resistant tool steel according to the German DIN 17350 standard. It has the same compositional range as 1.2550, a density of 7.93 g/cm³, a modulus of elasticity of 200 GPa, a hardness of 58-62 HRC after quenching (oil cooling at 860-950°C) and tempering, and high tensile strength (≥2100 MPa) with excellent fatigue resistance.

1.2550 Tool Steel | 60WCrV7 Types and Options

The table below shows the size range, surface condition and tolerance details for 1.2550/60WCrV7 Tool Steel:

1.2550 Tool Steel | 60WCrV7 Customized Options

- Customized chemical composition: GB, DIN, ASTM, JIS and other standard grades can be produced. Chemical composition can be customized individually.

- Customized specifications: round steel (diameter), plate (thickness, width) can be customized production.

- Specialized packaging for long term storage or extreme transportation conditions: includes spraying black paint all around, wrapping plastic film, spraying anti-rust oil, and shipping in wooden crates.

- Customized production based on samples or technical agreements.

- 1.2550/60WCrV7 Tool Steel Electroslag Remelting (ESR): premium option with higher purity and isotropic properties for critical applications.

1.2550 Tool Steel | 60WCrV7 Chemical Composition

1.2550 Tool Steel | 60WCrV7 Heat Treatment Process

1.Annealing

2.Quenching

3.Tempering

4.Precautions

Heating process should control the rate of heating to avoid too rapid a rise in temperature leading to workpiece surface oxidation and decarburization. Protective atmosphere heating can be used or placed in the furnace charcoal and other anti-decarburization agent.

When quenching and cooling, choose the appropriate cooling medium and cooling method according to the shape and size of the workpiece to ensure the quenching effect while reducing the risk of deformation and cracking.

1.2550 Tool Steel | 60WCrV7 Quality Inspection

1.Surface Condition Inspection

2.Chemical Composition Testing

3.Dimension and Tolerance Inspection

4.Hardness test

5.Ultrasonic Testing

6.Microstructure Inspection

(1) Metallographic Analysis

FCS factory will use metallographic analysis instrument to detect the microstructure state after heat treatment, including carbide distribution, martensite morphology, residual austenite content, etc.

(2) Grain size rating

1.2550 Tool Steel | 60WCrV7 Technical Specifications

1.2550 Tool Steel | 60WCrV7 Product Applications

Key Application Scenarios

Cutting Tool Manufacturing

Our 1.2550 and 60WCrV7 tool steels excel in the production of industrial cutting tools where edge retention and wear resistance are critical. Manufacturers of industrial shears, guillotine blades and precision cutting tools benefit from 15-30% longer life than standard steels. Consistent heat treatment response ensures consistent hardness from batch to batch, reducing production fluctuations and quality issues. A metalworking supplier switched to 60WCrV7, reducing the frequency of insert changes by 40%.

Industrial moulds and punches

For cold work applications such as drop dies, forming dies and deep drawing dies, our tool steel combines wear resistance with toughness. Typical dimensional stability of ±0.10% during heat treatment ensures accuracy of critical components. 1.2550 is particularly suited to scenarios where impact resistance is required while preserving the cutting edge, with customer feedback of a 25% increase in maintenance cycle yield.

Woodworking Tools

High-end woodworking tool manufacturers choose 60WCrV7 for its excellent edge retention in industrial planers, speciality chisels and professional cutting tools. Even when cutting abrasive engineered wood, the material maintains a sharp edge for cleaner cutting and less maintenance. Shop tests have shown a 35 per cent increase in resharpening intervals compared to conventional tool steels.

Moulds for the plastics industry

When processing abrasive polymers and fibre-reinforced plastics, our tool steels extend the wear life of cutting, shearing and pelletising equipment. Uniform microstructure ensures consistent wear patterns, reducing the risk of accidental failure and material contamination. Plastics processors report more predictable maintenance schedules and less unplanned downtime.

Customised precision components

When applications require both wear resistance and precision, our tool steels are heat-treated for superior dimensional stability. Refined grain structure and controlled alloy composition reduce distortion during hardening for gauge blocks, measuring tools and high-precision industrial components where tolerances are critical to performance.

Industry-specific applications

- Automotive: stamping dies, dressing tools, shearing equipment for high-volume production

- Aerospace: precision cutting tools for special alloys and composites

- Woodworking: industrial planer knives, special cutting tools, production equipment

- Metalworking: shear blades, punches, forming dies for steel processing

- Plastics: pelletiser blades, cutting dies, wear parts for extrusion equipment

- Electronics manufacturing: precision cutting tools for PCB manufacturing and component moulding Cutting tools

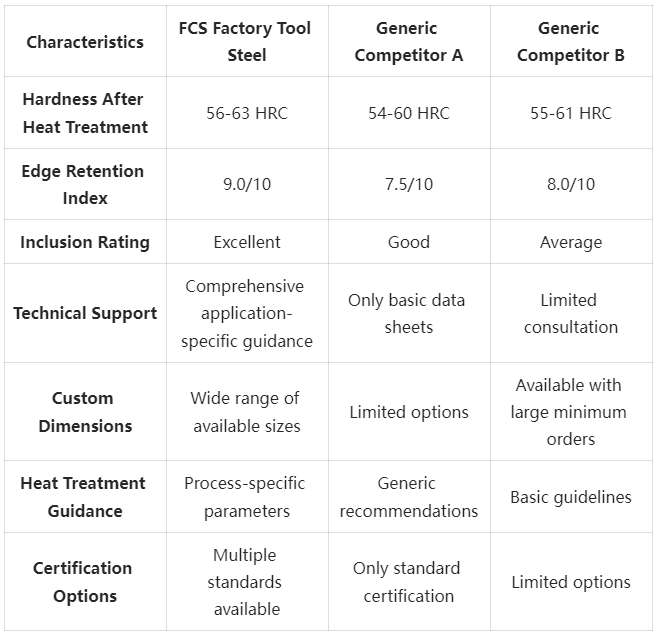

1.2550 Tool Steel | 60WCrV7 Competitive Advantage Comparison

1.2550 Tool Steel | 60WCrV7 Customer Success Stories

1.2550 Tool Steel | 60WCrV7 Pricing Structure Information

1.2550 Tool Steel | 60WCrV7 Frequently Asked Questions

Q: What are the standard sizes that can be delivered?

A: Standing common sizes: hot rolled round steel φ10-65mm, hot forged round steel φ70-700mm; hot rolled plate thickness 8-45mm, width 50-1000mm; hot forged plate thickness is 50-500mm, hot forged plate width is 50-1500mm.Q: What is the core difference between 1.2550 and 60WCrV7 tool steel?

A: Both are high-performance tool steels, but 1.2550 has superior toughness and impact resistance (56-58 HRC hardness) for shock load scenarios, while 60WCrV7 has superior wear resistance and edge retention (60-63 HRC hardness), making it the preferred choice for cutting tools and high wear applications.Q: What is the typical dimensional change during heat treatment?

A: Typical variation under normative heat treatment is 0.08-0.12% for 1.2550 and 0.10-0.15% for 60WCrV7, depending on geometric complexity and heat treatment parameters.

Additional information

| Weight | 45 kg |

|---|---|

| Dimensions | 165 × 60 × 25 cm |

-1.png)