I’ve often looked at kitchen appliances myself and wondered, “Is ‘brushed steel’ actually different from stainless steel?” If this sounds like, well, I can tell you you’re not the only one. Based on my experience, this distinction confuses quite a few people. I think there’s more to understand about these finishes than what we see on the surface. For example, I’ve noticed many people misunderstand why rust appears or why the prices differ so much. It seems there’s a bigger picture here. And I believe there’s one sneaky detail that people consistently miss…

Misconception 1: Brushed Steel is a Different Material Than Stainless Steel

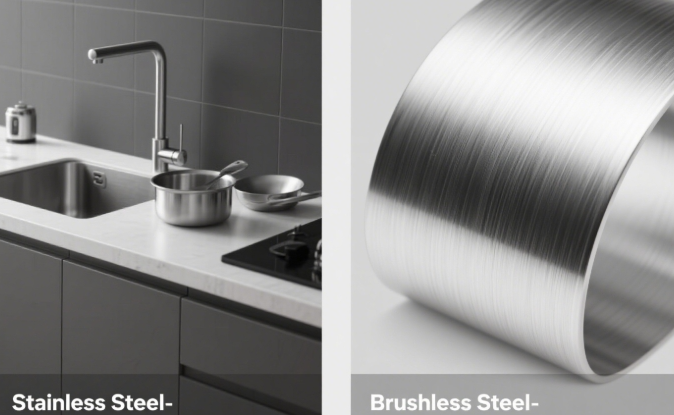

I observe that many people think “brushed steel” is a different type of material from stainless steel. Actually, brushed steel often means brushed stainless steel. It’s not a separate alloy.From my understanding, brushed stainless steel is standard stainless steel. Manufacturers treat it with abrasives like sandpaper or wire brushes.This treatment gives it a matte, linear texture. You’ll see fine, uniform grooves. I find this appearance is often called “satin.”The core makeup of brushed stainless steel doesn’t change. It still contains 10.5%–30% chromium and 0.03%–1% carbon. It also has added nickel and other elements for strength and corrosion resistance.

To sum up, I think the main point people miss is confusing the surface finish with the actual metal. Brushed stainless steel and standard stainless steel are made of the same stuff. The key difference is just how the surface is treated.

Misconception 2: Brushed Steel Resists Rust Better?

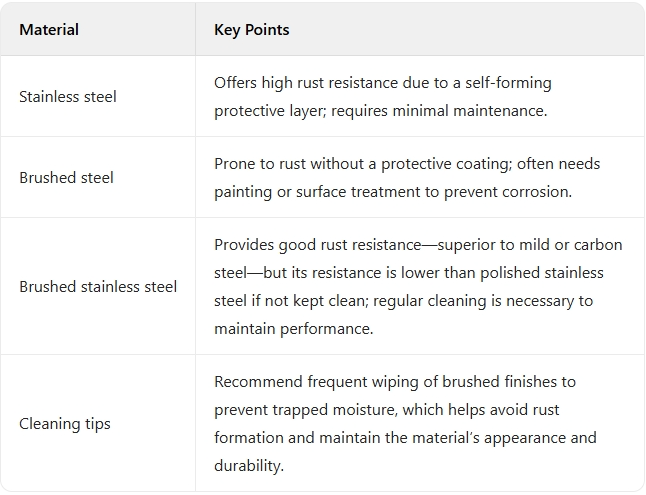

I find many people think brushed steel resists rust better than stainless steel. That’s incorrect. In my experience, what truly determines rust resistance is the metal’s makeup, mainly its chromium content. The finish isn’t the key.

Stainless Steel vs Brushed Steel: Let Me Explain Rust Resistance

Stainless steel has at least 10.5% chromium. I understand this forms a protective oxide layer on its surface. This layer acts as a shield. It stops rust from forming. Elements like nickel or molybdenum can make this shield even stronger. This is why I see stainless steel used where rust is a major concern. Think kitchens, hospitals, and ships.

Brushed steel is often carbon or mild steel. It has a textured, matte finish. I know it doesn’t have enough chromium. So, it can’t form that protective layer. This means it rusts easily. This is a big issue in wet areas or places with chemicals.

Brushed stainless steel is, in fact, stainless steel. It just has a special surface treatment. Its fundamental rust resistance remains good. However, I’ve noticed the tiny grooves from the brush finish can trap water and dirt. If you don’t clean it often, this trapped moisture might lead to small rust spots. Despite this, I believe it’s far more rust-resistant than plain brushed steel.

Real-World Performance: What I’ve Seen

I’ve seen data from salt spray tests. In these tests, stainless steel like grade 304 can go over 1000 hours before showing rust. Unprotected carbon steel, on the other hand, can rust in a few hours.I often see brushed stainless steel in busy places. Commercial kitchens and public elevators are good examples. This is because it resists rust effectively and maintains a good appearance.From my perspective, polished stainless steel gives the best rust protection. Its surface is the smoothest. This means there are hardly any grooves where moisture can collect.

Misconception 3: Brushed Steel Requires Less Maintenance

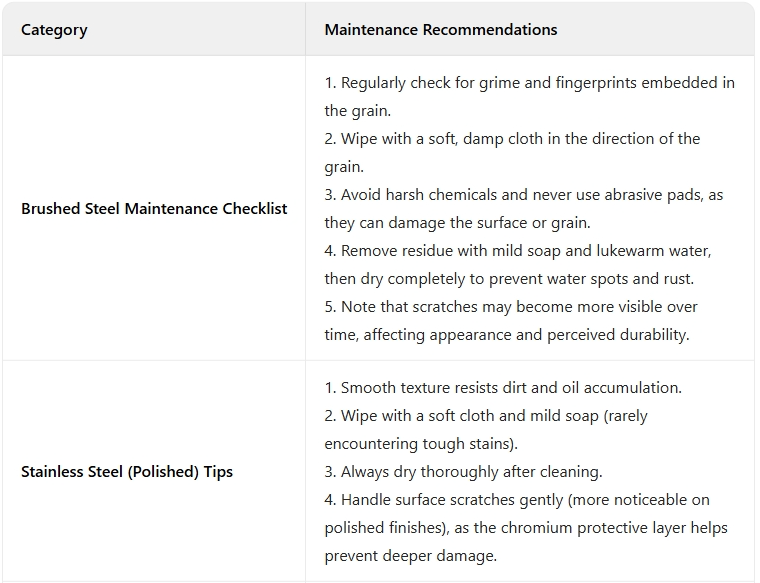

I’ve noticed many think brushed steel is easier to care for than standard stainless steel. From my experience, the opposite is often the case. I find that its special brushed surface has some unique cleaning challenges.

Brushed Steel vs Stainless Steel: Maintenance Realities

Brushed stainless steel has a surface with a grain and tiny grooves. I see this texture. At first, these grooves might hide small smudges and light scratches. This makes it look like it needs less cleaning. But I’ve seen those same grooves collect dirt, oil, and water pretty fast. If you don’t clean it, this buildup becomes hard to get off. I also think it can lead to a bit of rust or corrosion.

Standard (regular) stainless steel, like the polished or mirror kind, has a very smooth surface. I prefer this type for smoothness. So, dirt and grime don’t stick to it as easily. Fingerprints might show up more, so you might wipe it more often for a bright shine. But I find deep cleaning is simpler and you don’t need to do it as often.

Misconception 4: Brushed Steel Doesn’t Always Cost More

I’ve noticed a common misunderstanding: many think brushed steel always costs more than standard stainless steel. From my experience, this isn’t quite right. The actual cost difference comes down to several things. These include how it’s made, the quality of the metal, any special designs, and how much upkeep it needs.The final price really comes down to how it’s made, the metal quality, its size, any special requests, and what it needs for long-term care. If you want the best value, I recommend you look closely at the specific details of the product. You should think about both the initial price and any future costs. Don’t just use the surface finish to guess the price.

How Production Affects Brushed Steel Cost

I’ve found that brushed steel can cost more than standard stainless steel, and its finishing process is a key reason. Achieving that smooth, satin look requires an additional abrasion step. This involves using special, and sometimes expensive, abrasive materials. This extra production stage adds to the initial price. I also suggest you think about long-term care. Brushed finishes might show wear, like scratches or dullness, faster than polished stainless steel. This could mean more maintenance down the road.

Material Grades Make a Price Difference

In my experience, not all stainless steels have the same price tag. The quality of the metal, or its grade, really affects the cost. For instance, top-quality stainless steels like grades 304 or 316 are great against rust and last longer. This can make them more expensive than brushed steels made from lower-quality metal. I’ve seen situations where a polished, high-grade stainless steel actually costs more than a brushed steel that uses a less expensive base metal. So, I recommend looking at the grade closely.

How Size, Thickness, and Special Orders Affect Price

I’ve learned that the product’s size and how much it’s tailored to specific needs also change the final price. If you need larger items, thicker metal, or custom-made designs, the cost will go up. This applies to both brushed and standard stainless steel. On the flip side, if you order a large quantity, you might get a better price per item. This is because making things in bulk is often cheaper, no matter the finish. I always suggest getting quotes for your specific needs.

Misconception 5: Thinking Brushed and Polished Steel Are the Same for Everything

Brushed and polished stainless steel might seem alike. However, I know they have different jobs and uses. In my opinion, it’s wrong to think you can just swap them without any problems. In my view, brushed and polished stainless steel finishes both have unique advantages. I always recommend choosing the finish based on what the job needs. For example, you might want a scratch-hiding, modern look for busy spots. Or, you might need a spotless, mirror finish for places people see often or for sanitary uses. You can’t always use them interchangeably. Understanding the difference helps protect your money. It also leads to better outcomes, in my experience.

Key Differences in Appearance and Performance

Visual Impact and Texture:Polished stainless steel has a bright, mirror-like finish. It reflects a lot of light. I think it gives a clean, fancy look. Brushed stainless steel has a matte, soft texture. You can see fine lines. This finish cuts down on glare. I find it looks softer and more modern.

Scratch and Wear Resistance:Brushed finishes are great at hiding scratches and everyday scuffs. The grain in the texture hides small flaws. That’s why I see it used a lot in busy places. Polished finishes show every fingerprint and scratch easily. They look lovely initially. But, they show wear fast in active areas if you don’t maintain them with care. I’ve noticed this happens.

Grip and Practical Function:The grain on brushed stainless helps with grip. It makes surfaces less slippery. I find this very useful for handles and commercial kitchen equipment. It’s also good where you need slip resistance. – Polished steel is glossy and smooth. So, it doesn’t offer extra grip.

Misconception 6: Does a Brushed Finish Change Stainless Steel’s Basic Properties?

I’ve noticed many people think that brushing stainless steel changes its core properties or makes the metal weaker. That’s not true. A brushed finish does not alter stainless steel’s fundamental material properties. Brushing is a surface treatment that modifies texture and appearance but leaves the alloy’s core characteristics intact.

Practical Impact:

While the brushed finish hides scratches better than polished surfaces, it does not inherently make the steel “softer” or more prone to wear. Any perceived durability differences stem from maintenance habits, not material degradation.

In summary, brushing alters only the surface aesthetics, not the intrinsic properties of stainless steel. Its corrosion resistance, strength, and thermal stability remain unchanged. Proper care ensures brushed finishes maintain both functionality and longevity, leveraging stainless steel’s core advantages while adding visual and practical benefits.

Misconception 7: All Stainless Steel Has a Shiny Appearance

I find that many people think all stainless steel is shiny. That’s not quite right. In my experience, stainless steel actually offers many different finishes and appearances. How it looks depends on how manufacturers make it and the type of steel they use.So, from my perspective, it’s clear: not all stainless steel is shiny. The finish and the type of alloy actually decide how it looks. This can range from a soft matte to a very reflective mirror surface. So, if you’re picking stainless steel for a project, I recommend you choose a finish that fits both how you want it to look and what you need it to do.

Misconception 8: Brushed Steel is Less Durable

A common misconception is that brushed steel is inherently less durable than standard stainless steel. This claim misunderstands the relationship between material and finish. Brushed stainless steel retains the same corrosion resistance and structural integrity as its polished counterpart, as both rely on a chromium-rich alloy (≥10.5% chromium) to form a protective oxide layer. The brushed finish’s textured grain even enhances practicality by concealing scratches and improving grip in high-use settings like kitchens or public infrastructure. While micro-grooves may trap debris, routine cleaning prevents long-term corrosion risks. Alloys such as 304 or 316 further bolster durability against chemicals, heat, and wear. Far from being weaker, brushed stainless steel combines stainless steel’s inherent strength with a low-maintenance, damage-masking surface, making it equally—or more—durable in real-world applications where aesthetics and functionality intersect.

Misconception 9: Brushed and Polished Steel Don’t Perform the Same

Brushed and polished stainless steel finishes differ significantly in functionality beyond aesthetics. Brushed steel features a textured, matte surface with fine grooves, offering better grip and effectively concealing scratches, fingerprints, and wear. This makes it practical for high-traffic areas like kitchen tools. However, its textured surface traps dirt and moisture, requiring meticulous cleaning to prevent localized corrosion. In contrast, polished steel boasts a smooth, mirror-like finish that’s easier to sanitize but highlights fingerprints and scratches prominently. While both finishes share the same corrosion-resistant base, polished surfaces’ non-porous nature minimizes water retention risks, whereas neglected brushed surfaces may corrode due to trapped contaminants.

Cost and maintenance preferences further distinguish the two. Polished finishes demand labor-intensive buffing to achieve flawless surfaces, often increasing production costs. Brushed finishes are generally more affordable but may require specialized cleaning to address ingrained grime. Industry experts emphasize that performance gaps are tangible: brushed steel prioritizes durability and low maintenance visibility, while polished steel emphasizes aesthetics at the expense of frequent upkeep. Choosing between them hinges on prioritizing visual appeal versus practicality, factoring in usage environment, cleaning commitment, and budget constraints. Neither finish universally outperforms the other, but their distinct characteristics cater to different functional needs.

Misconception 10: All Grades of Stainless Steel Are the Same

A widespread assumption is that stainless steel grades universally share identical properties, but this overlooks critical distinctions. While all stainless steels contain chromium for corrosion resistance, varying compositions of nickel, molybdenum, and carbon differentiate their performance. For instance, Grade 304 (18/8 stainless) excels in everyday applications due to its balance of durability and affordability, whereas Grade 316 includes molybdenum for enhanced resistance to chlorides, making it ideal for marine or medical environments. Specialty grades like 430 prioritize cost-efficiency but sacrifice corrosion resistance, while high-temperature alloys like 310 withstand extreme heat in industrial settings. These variations directly impact strength, corrosion tolerance, and thermal stability.

Choosing the wrong grade can lead to premature failure. A restaurant using Grade 201 (low nickel) in humid kitchens may face rust issues, while construction projects in coastal areas require Grade 316 to avoid saltwater degradation. Even surface finishes—brushed versus polished—affect performance in specific contexts. Manufacturers and consumers must prioritize application-specific needs over generic assumptions. Stainless steel’s versatility lies in its tailored formulations, not a one-size-fits-all approach. Ignoring these nuances risks costly repairs, safety hazards, and wasted resources—proof that not all stainless steel is created equal.

summary

Looking into common wrong ideas about stainless steel has helped me appreciate its subtle qualities. I find that understanding the differences between brushed and polished finishes lets me make smarter choices for my projects. For me, it’s not just about how it looks; it’s about picking the correct type for each specific job. Learning the truth about stainless steel’s characteristics, finishes, and care requirements means I can choose options that look good, work well, and last. I believe the right information is key to my work with these adaptable materials.